Continuous fryer MS

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

Our continuous fryer is ideal for frying scallops, potatoes, croquettes and many other products. Ideal for catering companies, food firms or school kitchens.

It is manufactured in stainless steel and consists of double metal conveyor belt with independent motion. The speed of the belt is adjustable depending on the frying time.┬Ā

The heating system can be electric or mixed electric/steam. Included is a specially designed lid for the steam evaporation produced during the frying. The fryer also includes a lower tank for storing the used oil. Recirculation pump is used for oil transfer and providing an ideal consistent oil temperature.

The machineŌĆÖs oil filter is placed in the recirculation pipe, which is constructed from stainless steel together with other accessories and taps. Low voltage touchscreen for the operating of the equipment. There is an option for running different programs. The machine dimensions can be customized according to the product and customerŌĆÖs needs.

CONTINUOUS FRYER - TECHNICAL SPECIFICATIONS:

- External dimensions 3400x850xH1000

- Basin internal dimensions 3400x600x H350 (useful 2200)

- External dimensions with conveyors 4000x850x H=1000

- Useful length frying 2200 mm

- Belt width = 420 mm

- Electric power, 72 kw.

- Oil storage tank for oil to be reused

- Constructed in stainless steel, 18/8 AISI 304

- Oil filter

- Automatic lifting of the belt for cleaning of the

- machine

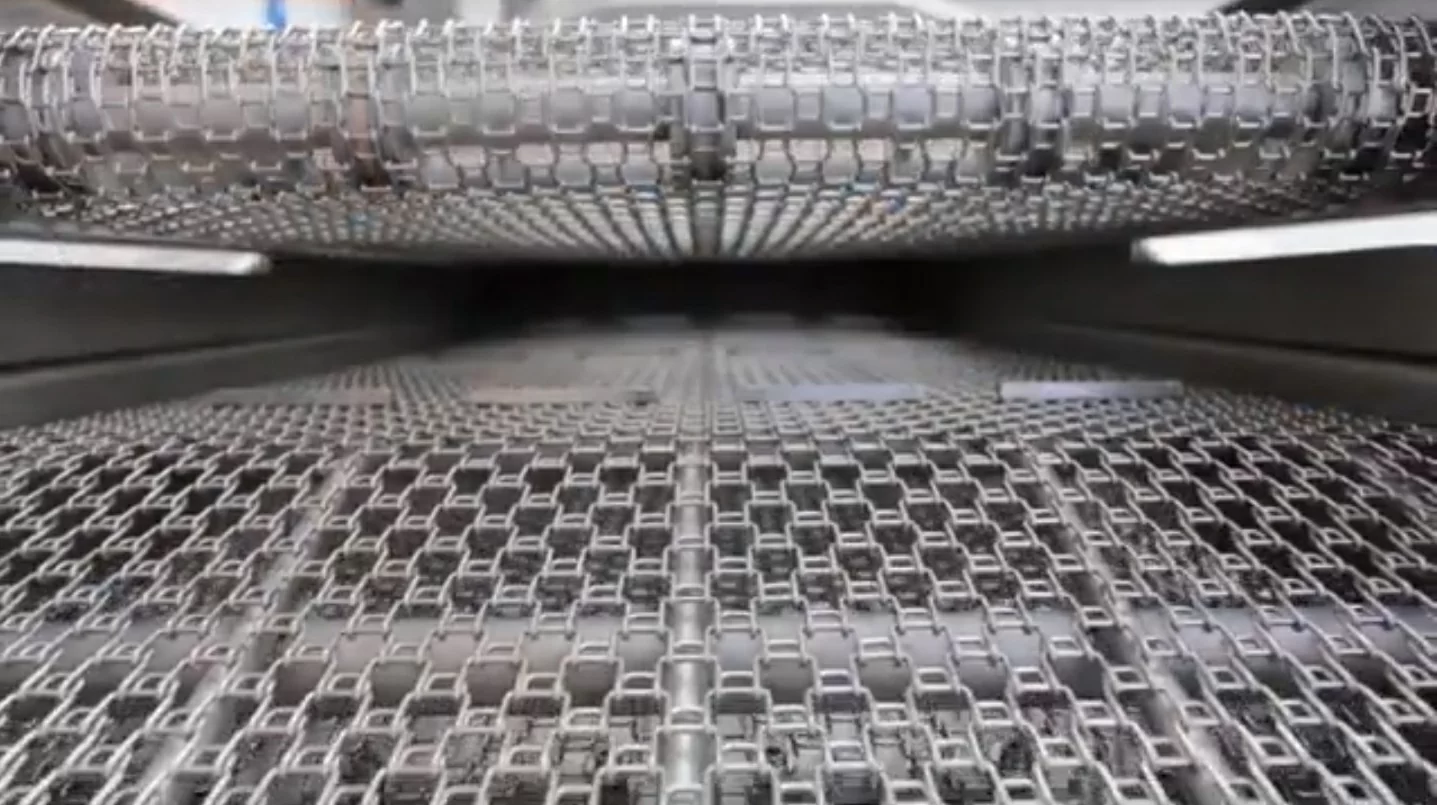

- Conveyor model compact Grid belt model 10x1,6

- Transfer oil pump from the tank bottom to top for recirculation of oil in the frying pan during the operation.

- The electric resistances immersed in the frying oil

- Oil temperature control with automatic regulation, and limit safety temperature.

- Dashboard low voltage touch screen to control the various parameters of the machine, and to perform maneuvers for cleaning. Supports the implementation of work programs.

- Two stainless steel conveyor belt driven by two geared variable speed engines. Distance between belts adjustable between 60 and 90 mm

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

You might also like

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.

- Productivity: 160 kg/15 min

- Material: Stainless steel

- Heating power, kW: 90/ 110/ 180

- Country of origin: Slovakia

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

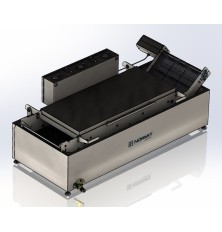

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized┬Āproduction facilities.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.┬Ā

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

- Material: Stainless steel

- Heating power, kW: 12

- Country of origin: Slovakia

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.

- Productivity: 160 kg/15 min

- Material: Stainless steel

- Heating power, kW: 90/ 110/ 180

- Country of origin: Slovakia

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The automatic donut forming and frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Weight: 40

- Total power, kW: 3

- Voltage: 220-230V

- Dimensions, mm: 965 x 330 x 650

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

- Material: Stainless steel