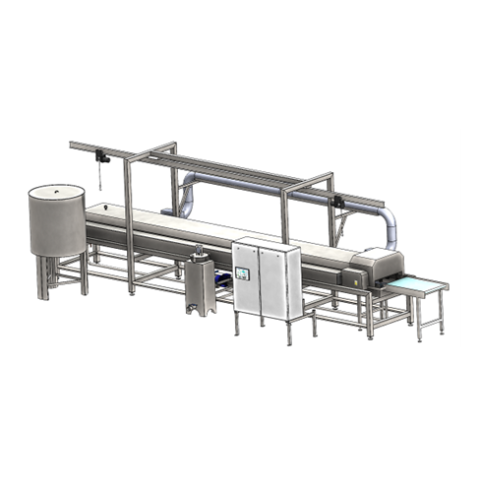

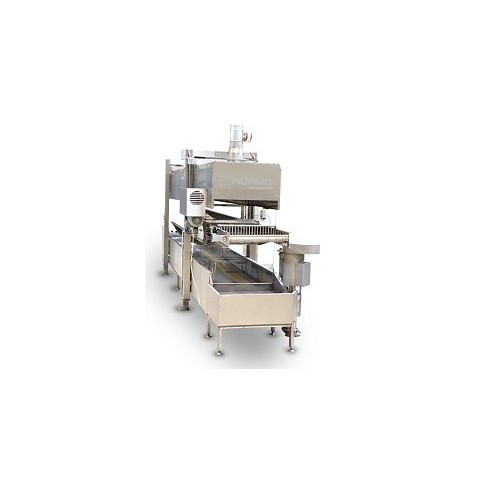

Industrial deep oil continuous fryers are designed for frying and deep-frying vegetables, mushrooms, frozen foods, french fries, meat and fish, dumplings, nuggets, onion rings, squid, crackers, popcorn, confectionery and other baked goods, donuts, cookies, spring rolls and crunches.

The Normit OilDeep deep fryer is useful for cooking various types of food and it is also a good solution for the problem of frying large amounts of food in a short time.

Normit OilDeep type of oil processing, designed for frying food in breadcrumbs, is simple and effective. It is fast and efficient thanks to its oil coating system. It maintains a simple oil flow and temperature across its entire width. The oil is filtered and circulates continuously. Thanks to this oil coating system, foods consume significantly less oil and are healthier than deep-fried foods.

Advantages of the Oil Deep Continuous Fryer:

- The higher quality of fried foods has a positive effect on taste and smell.┬Ā

- By using this deep fryer, you will be able to achieve a uniform and homogeneous┬Āappearance of the final product, the surface of which will be golden brown.

- The use of the device leads to excellent quality of end products good for their easy digestion.

The Deep Fryer is equipped with an oil filtration system that continuously filters the oil inside the fryer to prevent small pieces of burnt food from accumulating inside and resulting in quality degradation.

The continuous oil filtration system can significantly reduce the frequency of oil changes, which is cost effective and also reflects in the final products. Continuous oil filtration system extends the oil lifespan.

The OilDeep fryer is equipped with a feed control system that allows you to individually adjust the oil flow and parameters such as feed rate, optimal oil level, the volume of oil and its temperature. The oil control system helps you set the optimal frying conditions for your product. At the same time, it allows you to fry several different types of food in the same appliance simply by changing the parameters.

The plant is additionally equipped with an oil circulation system. The circulation of oil between the product and the heat exchangers, where the oil is only heated for a few seconds, prevents the formation of harmful carcinogenic substances in the oil. Thanks to this innovative heat exchanger, the oil cools down quickly after frying. The fryer is also equipped with an oil level maintenance system. Thanks to this system, the oil volume is automatically maintained at a certain set level.

Advantages of the industrial continuous deep fryer:

- Low oil consumption. This fryer uses significantly less oil (oil is only needed to coat the food; no deep frying is needed) and is a much healthier frying process. The total amount of oil needed is 25-40% less than the amount needed for deep frying. As a result of this type of frying, finished products are prepared quickly as well.

- Industrial Design. A well-thought-out position and technology allow the most efficient use of workshop premises. If your room size is limited or if you have any other special requests, production can be adjusted to suit your needs and requirements.

- Easy Maintenance. All elements and parts of the fryer can be easily dismantled for cleaning and maintenance. Any other items (oil storage tanks, filters, etc.) are placed at an optimal distance from the fryer so that their contact is kept to a minimum. This gives personnel easy access for cleaning, inspection and maintenance.

- Adjustable belt speed. The speed of the conveyor belts can be adjusted according to the time required to prepare the product and based on the pre-selected end products.

- Versatility and even fast cooking. The immersion fryer can be used to cook various types of food by simply changing the production capacity. Thanks to precise temperature control and fast oil flow, high quality end products can be guaranteed while preserving their flavor and aroma.

- High performance fryer with low power consumption. The high performance and low power consumption is achieved through using high quality materials and the well-balanced use of the most modern technologies. The result is a high quality finished product with low energy consumption.

- A simple way to operate the fryer results in minimal operating requirements.

- Controls include overload and undervoltage protection, as well as total network failure protection.

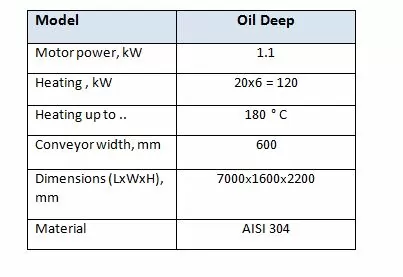

Technical details:

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The inspection conveyor is designed for inspection and manual removal of unsuitable pieces of root vegetables, fruits and berries.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

CAC Air cooling conveyors are designed for intensive cooling and removal of excess water or oil (air knife section) from products after frying, cooking or blanching.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 500 mm

- Voltage: 380-400V

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

EcoFry is designed for frying onion rings, seafood, dumplings, spring rolls, pies, vegetables, nuggets and hamburgers with the help of pouring hot oil. A smaller capacity, efficient frying equipment intended for small to medium sized┬Āproduction facilities.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 36

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960Ōé¼. The possibility of adding an oil spraying / pouring module (combifry), for an additional cost of 3980 Ōé¼ (RECOMMENDED OPTION)

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

An adjustable electric donut fryer with a continuous conveyor system is specially designed for small confectionery shops, pastry production and catering establishments. It is capable of frying a variety of products similar to donuts.

- Material: Stainless steel

- Heating power, kW: 12

- Country of origin: Slovakia

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.┬Ā

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode