Vacuum paddle meat mixer

Vacuum paddle mixers are designed for fast and precise mixing meat-mass in a vacuum. Used in meat production in meat processing factories.┬Ā

Vacuum Paddle Meat Mixers are designed for fast and precise mixing meat-mass in vacuum.

Used in meat production in meat processing factories. This machines use a dual system of mixing paddles which allows for precise and steady mixing of all stuffing ingredients.

VACUUM MEAT MIXER - SUITABLE PRODUCTS:

- Meat mixed with spices

- Meat hash

- Minced meat

MAIN CONSTRUCTION FEATURES OF A VACUUM PADDLE MIXER:

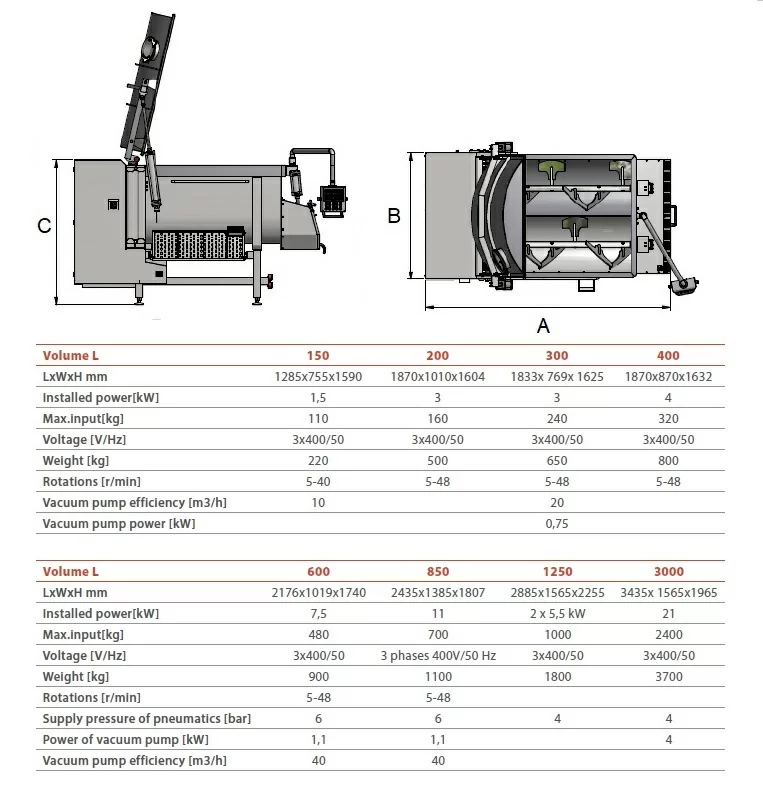

One or dual shaft system with mixing paddles, smooth, variable speed of mixing by using inverter; clockwise and anticlockwise rotations, 100% of stainless steel, manual tilt of mixer during unloading for 150L vacuum mixer, pneumatic loading and unloading system for the rest of the vacuum mixers; vacuum system (Busch pump); in 200L mixer, there are solid, full metal mixing shafts; meat-mass unloading adapted to standard 200 liter stuffing trolley for the mixers with capacity 300, 400, 600, 850, 1250 and 3000L. 600L, 850L and 3000L vacuum mixer is adapted for the loading pillar (optional); 1250L has two speed motors and right, left rotation. 3000L vacuum mixer has two speeds of mixing; water dosing system; load cells system, loading and emptying valve opened and closed pneumatically, loading pillar (optional); manual or automatical control of mixing. All components, such as engine and vacuum system are located in the cover, and access to them is possible only when cover is removed. Electrical installation is located in box on the side of the machine

HOW THE VACUUM MIXER WORKS:

Mixers have a variable direction of rotation of paddles and variable speed of mixing by using inverter. Whole machine is made of stainless steel, it allows to keep it clean. The mixing process can be carried out in a vacuum at a pressure of 0.07 mpa or at atmospheric pressure. Mixers have a variable direction of rotation of paddles and variable speed of mixing. Machine is integrated with loading pillar which can load standard 200 L trolley for meat-mass.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 3000

You might also like

Hydraulic piston fillers for the food processing industry, filling machines for meat and sausages, ideal equipment for meat industry producers and butchers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Volume: 20l/ 30l/ 50l

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

Stainlees steel free standing mixer for meat and dough.

- Material: Stainless steel

- Engine power, kW: 0,75 1,1

- Principle of operation: Batch mode

- Volume: 40 60l/ 80l/ 120l

The dough mixer is a batch type mixing equipment, working in the opposite direction, to produce a wide range of dispersions and emulsions of varying viscosity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Shaker mixer SMU6 is designed for mixing the contents of packaged products that are in foil or other protective packaging. The device is used in the food, pharmaceutical, chemical, construction and cosmetic industries, where it is necessary to thoroughly mix the contents without damaging the packaging.

- No need to remove the product from the packaging - mixing takes place in the original packaging

- Hygienic and safe mixing without contamination

- Robust and durable construction made of stainless steel AISI 304

- Material: Stainless steel

- Country of origin: Slovakia