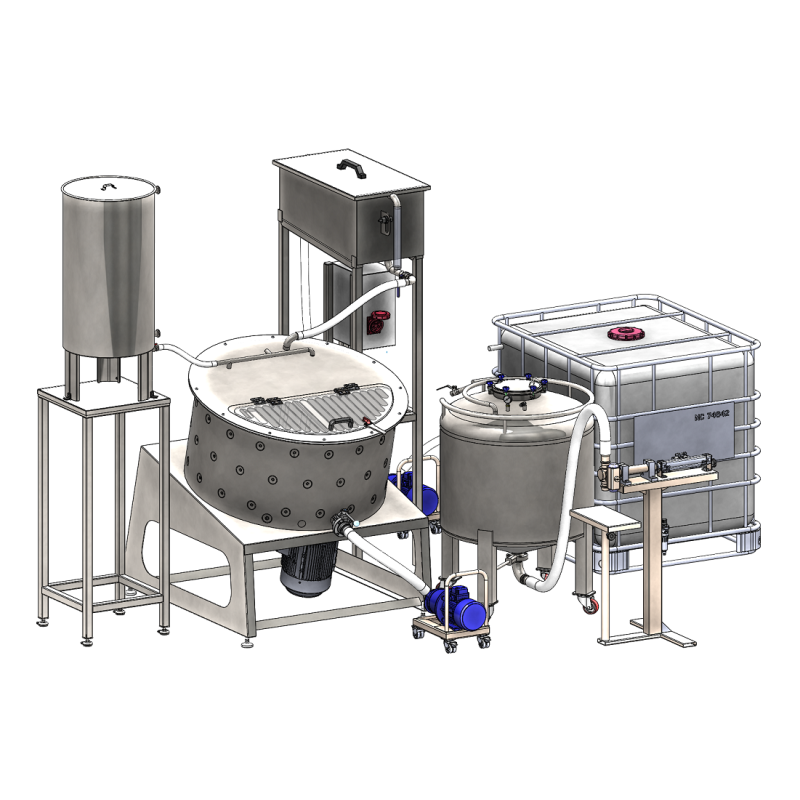

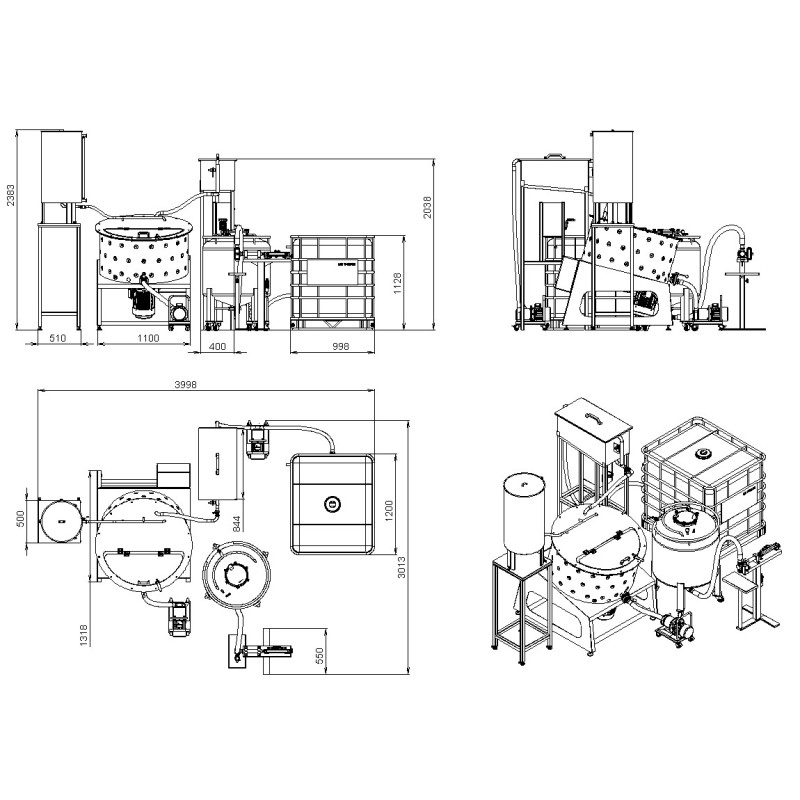

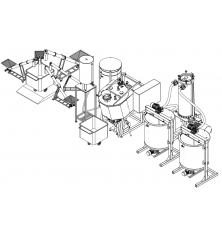

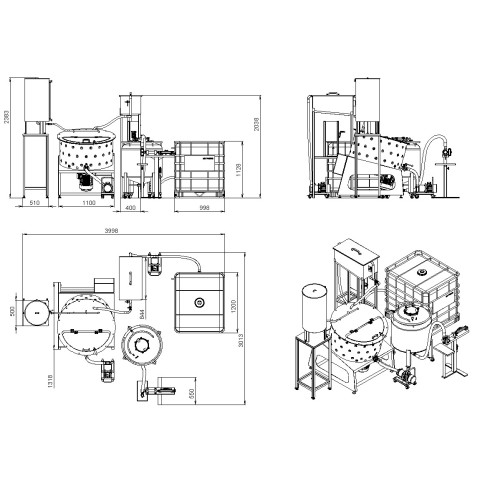

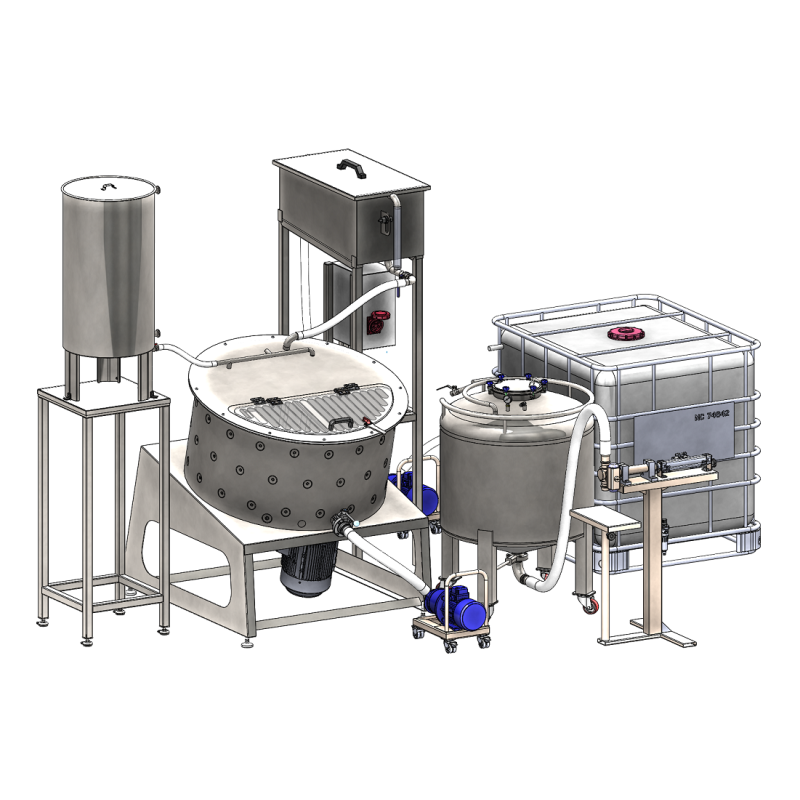

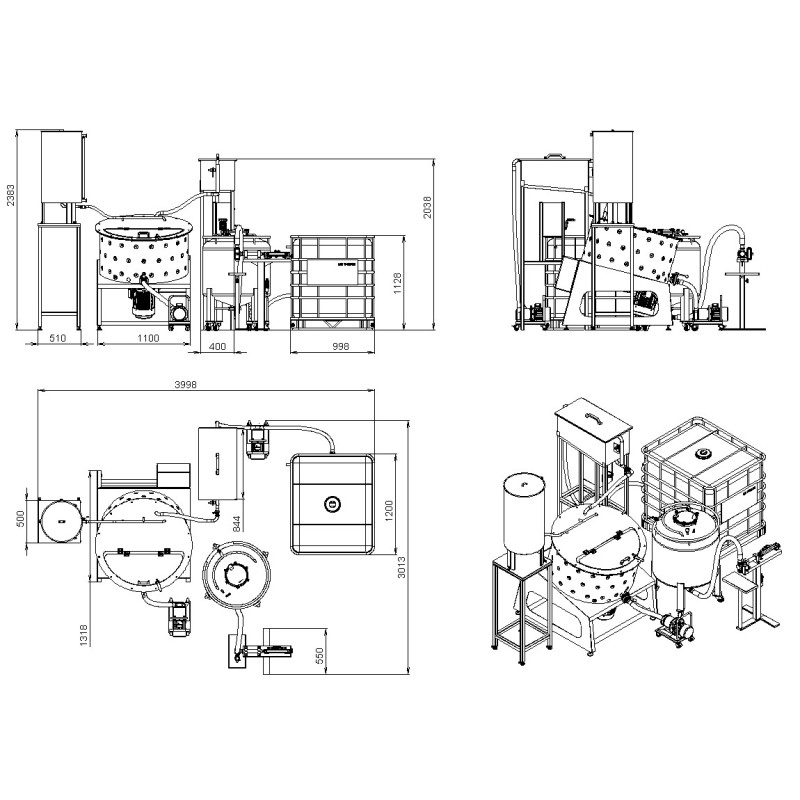

Mayonnaise production complex based on an atmospheric cutter 300

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

The primary technological installation for mayonnaise production is based on a universal atmospheric cutter equipped with cutting knives and a mixing device.

This equipment complex serves as a simple and convenient solution for mayonnaise production for small and medium-sized enterprises, allowing for the creation of mayonnaise-based sauces with various additives such as vegetables or seasonings.

Advantages:

- A cost-effective solution for precise dosing without requiring a substantial financial investment in an automation system.

- The cutter allows not only for the production of a stable emulsion but also immediate mixing with various additional ingredients in a single installation.

- The presence of a "jacket" for the coolant around the cutter allows for even thermal treatment of the finished mixture/mayonnaise/sauces, depending on the production technology (when the coolant is supplied from an external heating/cooling source).

- High efficiency with gravitational mixing is achieved through the inclined design of the cutter.

- In the basic configuration, suspended scrapers are already installed on the frame mixing device.

- The upper housing of the unit is designed to accommodate the installation of CIP heads for washing (optional).

Basic version and processes

For auxiliary (preparatory) processes, reactors/dosing machines operating on the principle of gravity loading are utilized.

Presented separately is a water dosing machine equipped with an automatic filling system based on the level sensor settings in the installation (requiring a permanent connection to the water supply system). For each dose, the required water volume is determined and set based on the level sensor, which, after opening the «vessel â cutter» direction, flows into the cutterâs working container by the force of gravity. For the next dose, the automation opens the electromagnetic valve and again allows in the volume of water set by the level sensor from the water supply.

The oil dosing vessel, incorporating a special self-priming oil pump, operates on the same principle. The pump of the dosing unit, connected to an oil container via flexible pipelines, automatically releases a dose of oil into a single portion of mayonnaise production using an installed level sensor. Following this, utilizing the gravitational principle, the oil is loaded into the working container of the cutter.

After adding liquid ingredients, other components can be introduced into the cutter through the upper housing hatch.

The cutter is equipped with special knives featuring a high-power electric drive. Due to the inclined design, the product is guaranteed to be directed to the lowest hydraulic point where the cutting knifes are installed. The mixing device, utilizing the gravitational mixing principle, intensively mixes the resulting emulsion, distributing the ingredients throughout the whole mass, creating a homogeneous final product.

Options:

- Rotary heads for CIP cleaning of cutters

- Pump for pumping the finished product

- Container for the finished product

- Mayonnaise dosing systems

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

You might also like

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V

A universal homogenizing module for mayonnaise production. The special compact atmospheric unit with a bottom homogenizer and a circulation system allows to create stable fat emulsion in just a few minutes!

- Compact design

- No dead zones and corners due to the conical shape of the unit

- Powerful bottom inline homogenizer with circulation

- Hygienic design

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 9

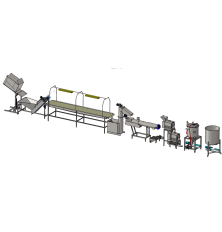

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk or normalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Our hydrodynamic extraction line is designed for extracting various components from plant materials, including biologically active substances, proteins, fats, carbohydrates, antioxidants, dyes, and flavors.

- Effective âsoftâ continuous hydrodynamic extraction â percolation from finely crushed raw materials.

- Extraction without the need for pre-drying the product, resulting in savings on labor and energy costs.

- Utilizing raw materials without heat treatment, preserving all of their valuable substances and enzymes.

- Possibility of performing vacuum-pulse extraction (optional).

- Additional income from processing âwasteâ products - extracting valuable components from pulp and pomace.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia