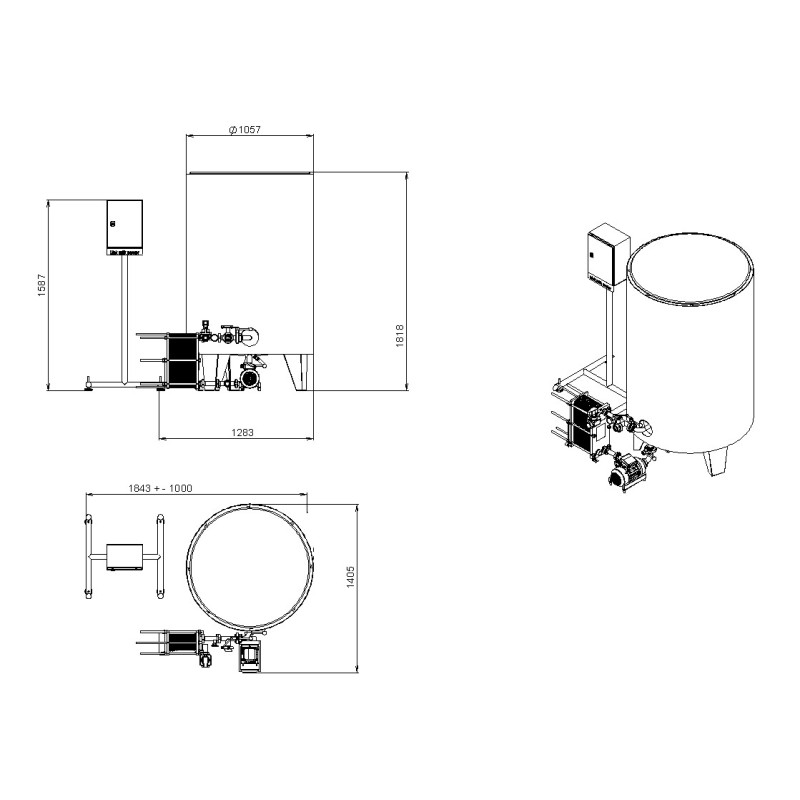

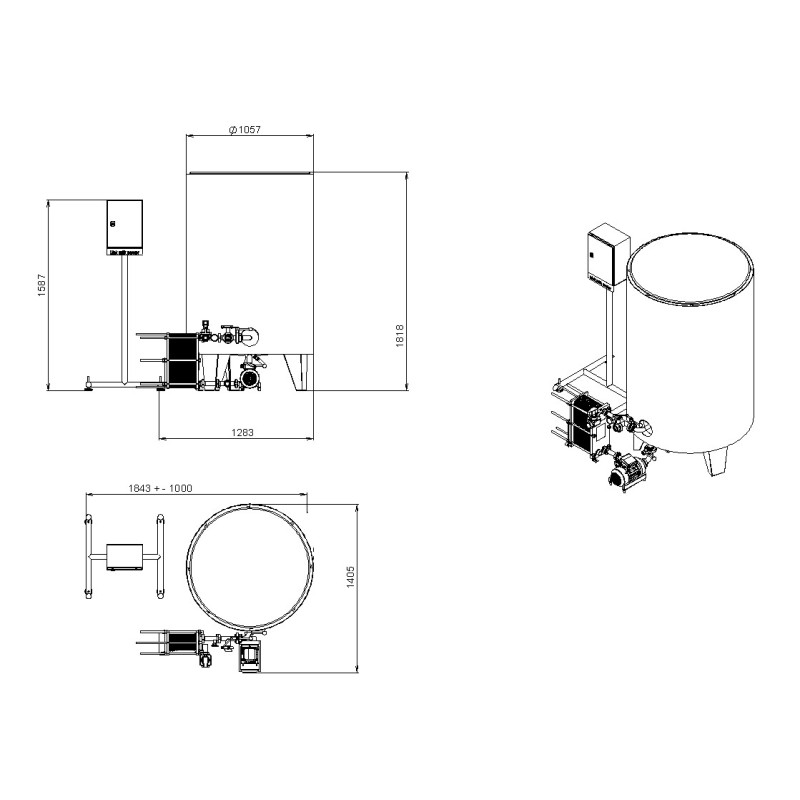

Milk pasteurizer - 1100 L

The long-term pasteurization tank is a compact solution for the heat treatment of milk in order to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period of time. The special design allows not only for pasteurization of milk in the flow, but also for sequential cooling, by feeding cold water into the heat exchanger after heating.

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- Can also be used as both a pasteurization and cooling unit

- High-performance milk pump

- Compact vertical design

The milk pasteurizer allows for heat treatment in long-term pasteurization mode while maintaining a specific temperature. This process eliminates nearly 98% of bacteria and pathogenic microflora without destroying the protein and preserving the organoleptic properties of milk. Rapid cooling quickly lowers the temperature of milk after heating, which effectively preserves the delicate enzymes and proteins, prevents thermal damage, and ensures that the milk retains its fresh taste, desirable texture and nutritional quality.

The long-term pasteurization bath is an ideal solution for compact small-scale production involving the processing of milk in small volumes, such as the production of sweetened condensed milk from whole normalized milk.

Advantages:

- A special feature of this unit is the ability to use it for subsequent rapid cooling of milk in the flow. The design of the unit allows steam to be supplied to the heat exchanger, as well as cold water for intensive cooling to the required temperature.

- Highly efficient and intensive steam heating through a heat exchanger allows for the rapid attainment of the pasteurization temperature, with steam flow regulated by a temperature sensor.

- High milk flow rate is achieved due to the forced external circulation circuit. The unit is equipped with flow temperature sensors to prevent localized overheating or burning of the milk.

- Intensive heat transfer occurs through hydrodynamic mixing of the milk during constant circulation, which prevents possible stratification of the product into fractions. There is no need to install a mixing device!

- The unit is entirely made out of stainless steel, including the milk pump, all piping and shut-off valves in the circulation circuit.

- It features a compact vertical design with a freestanding control panel.

- Due to milk entering the circulation circuit below the liquid level, the likelihood of milk foaming during pasteurization is practically reduced to zero.

Basic Version:

It consists of a three-layer stainless steel tank (with thermal insulation and an external decorative casing), equipped with a forced external circulation circuit, a milk pump, a steam heat exchanger (up to 3 bar), a temperature sensor, and a control panel. Steam is supplied to the heat exchanger from an external source.

Options:

- Steam generator

- Touchscreen control panel

- Industrial controller-based control panel

- Additional cooling circuit for modifying the unit into a pasteurization and cooling unit

The milk pasteurizer can be custom-manufactured in different volumes and production capacities to meet specific requirements. Please contact us to discuss your desired volume capacity.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

You might also like

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

A cheese kettle is a specialized cooking vat used in cheese making processes to heat and curdle milk, allowing the separation of curds and whey. It provides controlled heating and agitation to facilitate the cheese production process. Working volume up to, l: 300 l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer different pasteurizers for different applications.

- Heating: Gas

- Productivity: 300 l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 220-230V

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

- Material: Stainless steel

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500l/ 650l

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

The cheese boiler is used in the dairy industry for the production of cheese grains during the production of natural hard, semi-hard, soft cheeses, and other cheese or curd products. The cheese maker is equipped with a special knife-mixer (lyre) for cutting the cheese curd. Suitable for both small and large scale production. Using this cheese-cooking boiler you can also pasteurize other dairy products, produce yogurt, cottage cheese kefir, fermented baked milk, varenets, sour cream and more.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode