Cooking kettle for making jam and pasteurizing jars

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

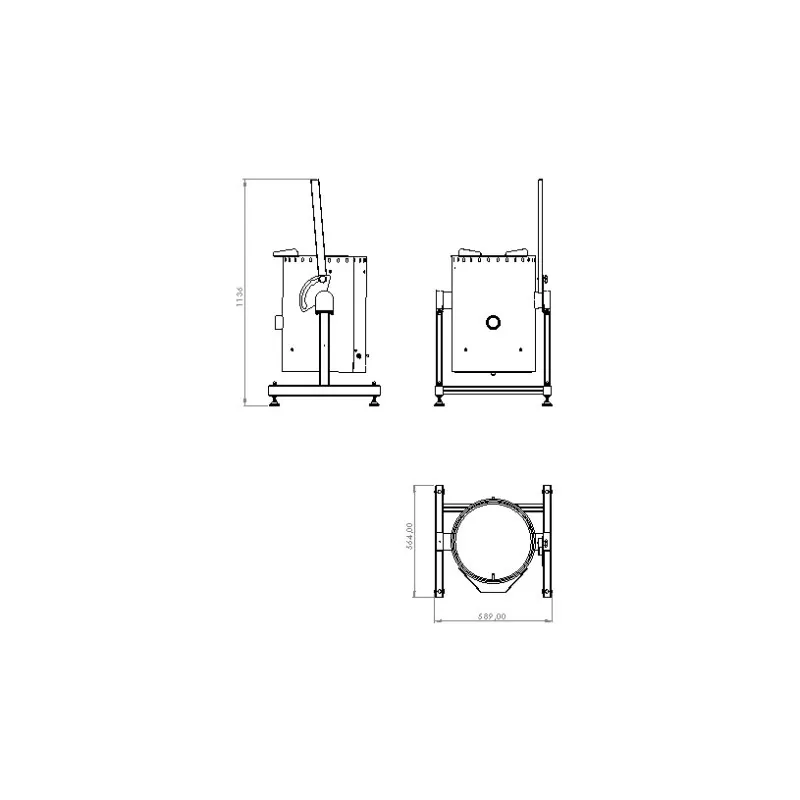

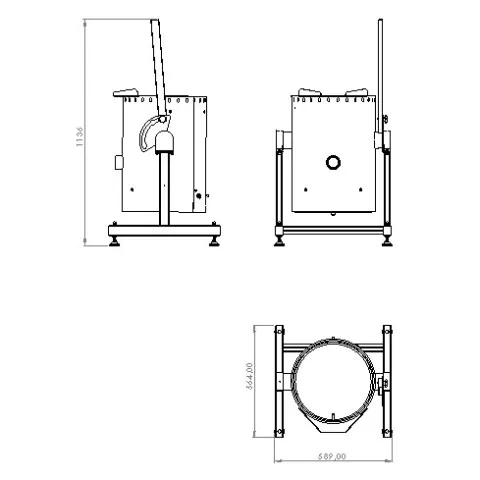

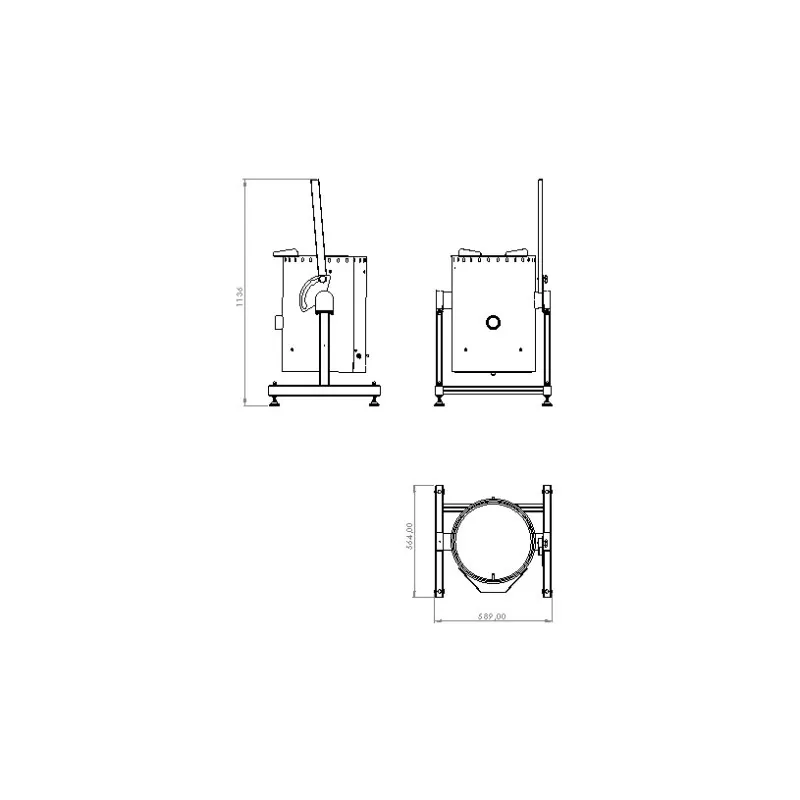

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110° ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

The multifunctional pasteurization kettle with a tilting system is a complete device designed for the entire jam production process, it is used for the heat treatment of fruit mass and subsequent pasteurization of the finished product directly in bottles or jars, which can be placed in a special basket (additional option). In one device, you can boil, fill and then pasteurize jam, which extends the shelf life without the use of preservatives and makes the entire production process more efficient.

The compact pasteurization kettle with electric heating and a manual tilting system is ideal for:

- cooking and pasteurizing jams, marmalades and fruit purees

- pasteurizing filled jars

Advantages

- A comprehensive solution in one device, from cooking the fruit mixture to pasteurizing finished products in jars without the need to transfer to other containers.

- The ability to boil and pasteurize directly in the same container significantly saves time and space in production.

- Heating and time control allows you to adapt the process to a specific product, preserving its taste, color and nutritional value.

- Energy-efficient design with even heat distribution reduces energy consumption and prevents the product from burning, even during prolonged heating.

- Safe handling thanks to the location of the controls in the "cold zone" with an ergonomic tilting system that facilitates emptying and dosing without the risk of burns.

- Smooth inner walls and removable parts significantly reduce the time required for cleaning and maintenance.

- The shape of the container and the tilting design allow for complete emptying and efficient use of the entire batch.

Possibility of pasteurization of packages. Filled jars can be pasteurized directly in a special basket, which reduces the risk of contamination and eliminates the need for additional equipment.

The basic version includes

The device includes a cooking vessel with an outer shell, a supporting structure, integrated heating, a temperature sensor, a safety lid opening sensor and a manual tilting system with three working positions and an angle of up to 110°.

Operating principle

The product is first boiled directly in the vessel at a controlled temperature. After the boiling phase is completed and the bottles are filled with the product, it is possible to proceed to pasteurization of the jars placed in a special basket. Uniform heating guarantees the safe destruction of microorganisms, minimizes the risk of contamination or boiling over and preserves the quality of the product.

Once the process is complete, the product is simply emptied using a manual tipping system that allows for complete emptying of the container.

The device can also be used as:

- tilting mixer

- tilting cooking kettle

- fat melter

- mixer for liquid products

- fruit blancher

Optional equipment

- Frequency converter as the control panel (IP65)

- Height-adjustable legs

- Heat transfer medium jacket up to 0.5 bar

- Drain valve

- Stainless steel mesh basket

Technical characteristics

- Material: stainless steel AISI 304

- Volume: 30 / 50 / 100 / 150 l

- Heating power: 2.6 / 5 / 6.5 kW

- Max temperature: up to 200 °C

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

You might also like

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer âsandwichâ base, allowing the heating temperature to reach up to 200 °C.

- High processing temperatures of up to 200 °C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.Â

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

It's compact cooking equipment for catering and gastronomic sphere: cafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Â

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

This stainless steel cooking pot will always ensure cooking, baking or boiling different foods.

- Material: Stainless steel

- Voltage: 380-400V

- Working volume: 100

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

Thanks to the indirect heating system, this electric kettle is ideal for cooking liquid foods. It is completely made of stainless steel and equipped with a convenient drain valve.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l