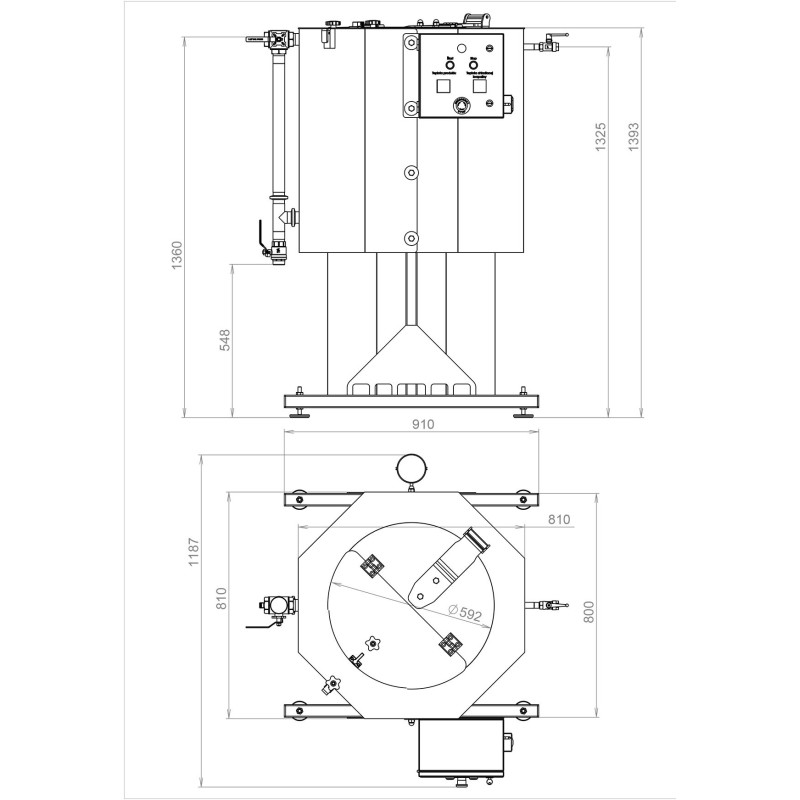

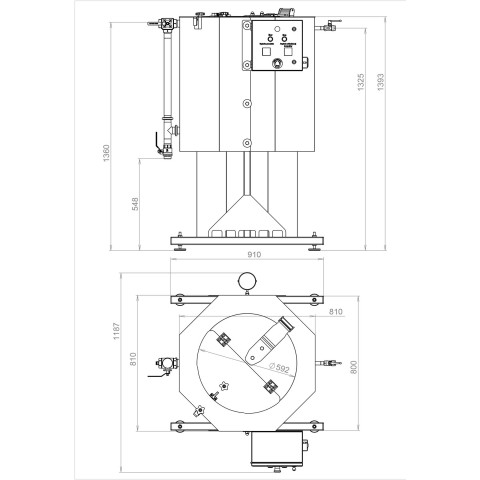

Homogenizer for Soy Milk Production MH 150/120

The price is set for the basic version of the installation for making plant milk without a steam generator

The Veggie Milk cooking kettle is used as a unit for hydrodynamic thermal extraction of substances from legumes and nuts to create a finished suspension - the basis of plant based drinks.

- Efficient and fast extraction

- Partial pasteurization due to direct steam injection

- High-powered bottom homogenizer

- Hydrodynamic mixing

- Mechanical shaft seal for the homogenizer with an open cooling system

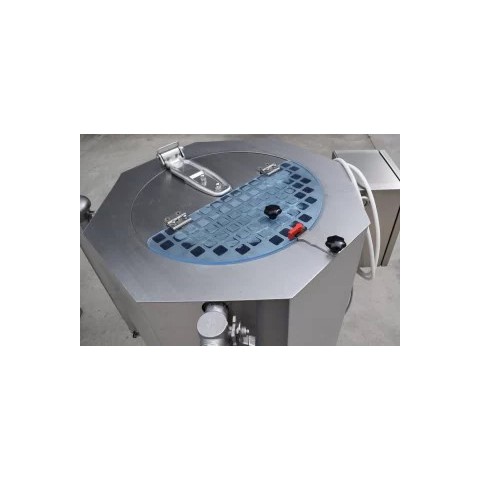

- Safety grid on the hatch cover for safe product loading

- Sectional plexiglass hatch for visual inspection

The Veggie Milk plant is used not only for industrial applications in the plant-based beverage industry, but it is also an integral part of the soybean processing process to produce tofu or other similar vegan products.

The plant milk homogenizer is suitable for the production of plant bases for beverages such as:

|

|

|

|

|

|

|

|

|

|

You can get a plant base from almost any nuts, grains or seeds.

Advantages:

- High efficiency and productivity, up to 100 liters of the base with a particle size of up to 100 microns is produced in just one cycle, the time of the cycle depends on the product, for soybeans - 5-10 minutes.

- A high degree of homogenization is achieved by the combined influence of the following factors: mechanical grinding and crushing, multi-level cutting, geometric linear speed acceleration, change in pulsating voltage, cavitation, ultrasound.

- Efficient Heating: Direct steam injection into the product is the most economical and intensive heating method with minimal inertia.

- An additional factor that increases the cost-effectiveness and efficiency of plant milk production using a plant milk homogenizer is the effect of converting the mechanical energy of the homogenizer into thermal energy, which allows for faster heating and saving on steam.

- Veggie milk has a hygienic design that is easy to clean. There are no dead zones where product can accumulate. The installation has a self-cleaning system: cleaning is carried out by circulating the cleaning agent and water throughout the homogenizer along the path of the product.

- A cooling system for the mechanical shaft seal, which protects the operation of the unit during dry running or when the volume of processed product is small.

- Thermal insulation for the working tank to reduce heat loss and ensure safe equipment operation during its use.

Processes:

|

|

|

|

|

|

* Steam generator - option

Basic version

The Soy Cow or Veggie Milk unit comprises an atmospheric reactor mounted on a supporting structure and a homogenizer with a┬Ā electric drive suspended at the bottom. It includes an extended stainless steel electric motor shaft, a mechanical seal, a perforated protective housing for the external rotary units of the homogenizer, an external circulation circuit, a direct steam supply system, and a sectional opening top cover. The unit is equipped with a frequency converter and an analog thermometer for measuring product temperature.┬Ā

Operating principle

The homogenizer grinds the product in a humid environment with the external circulation circuit turned on. Purified steam is introduced into the lower part of the apparatus through a specialized bubbling system, facilitating intense heat transfer, hydrodynamic stirring, mixing, and absorption. Direct injection of purified steam into the product allows you to significantly intensify the heating process with minimal energy losses, which also partially pasteurizes the product.

Options:

- Bottom decorative stainless steel housing

- Height-adjustable legs

- Support structure on wheels with locks (brakes)

- Changing the electric motor power within the size category of 132

- Time relay

- Water meter

- Steam control system

- Control with PLC controller

- Steam generator (control and safety fittings are not included in the basic delivery package)

Additional equipment:

- Vacuum coater for water saturation and soaking beans, grains and nuts

- Feeding conveyor

- Separator/centrifuge

- Okara press

- Steam purification filter

- Pasteurizer

- Productivity: 600 kg/h for soybeans

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 120l

- Total power, kW: 7,5

- Voltage: 380-400V

You might also like

The generator is mounted on a stainless steel platform support, covered with stainless steel AISI 304 properly shaped with electrical and water connections already made. Stainless steel cocks AISI 316, malleable iron pipe fittings, feed water pump (mod. TP78A CALPEDA) with 1 stainless steel non-return valve, with VITON seal.

For additional information, please email us at sales@foodtechprocess.com

- Heating power, kW: 24/ 32/ 48

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

For more information, contact: sales@foodtechprocess.com

- Type of the equipment: Optional equipment

Set of 4 height adjustable legs+/- 100 mm.

For more information contact: sales@foodtechprocess.com

- Material: Stainless steel

- Type of the equipment: Optional equipment

The new design of the universal cutter with gravity mixing is used for the production of thick and pasty products. The cutter is designed to carry out production processes such as cutting, mixing, crushing and emulsifying of various types of products to a liquid state. Thanks to the built-in duplicator, it can also be used as a device for the production of cream honey or cream honey souffl├®.

- Cutting knives with a powerful 11 kW electric drive

- Frame mixing device with fluoroplastic scrapers

- Hatch opening sensor for safe maintenance

- Plexiglass hatch for visual inspection

- Duplicator for the thermal liquid around the bottom as well as the walls of the installation

- Inclined design for efficient grinding, homogenization and discharge of thick and viscous products

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 12

- Voltage: 380-400V

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

For more information, send us a request at sales@foodtechprocess.com

- Engine power, kW: 0,55

- Principle of operation: Batch mode

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

Semi automatic packaging machine for filling and capping jars.

For additional information, please contact us at┬Āsales@foodtechprocess.com

- Material: Stainless steel

Used in chemical, construction, cosmetic or food industries.

For a price quote, send us an email to sales@foodtechprocess.com

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

- Volume: 50l

- Voltage: 380-400V

This mixing machine is intended for mixing┬Āsauerkraut with carrots, beets, salt, spices, also for salad, kimchi mixing etc.

For more information, send us an email at sales@foodtechprocess.com

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l/ 600l/

The conveyor is made out of strong and highly-resistant stainless steel. It is also additionally reinforced for reliability during operation.

For additional information, please contact us at sales@foodtechprocess.com

- Material: Stainless steel

- Principle of operation: Continuous mode

An open-type cream separator with a capacity of 1,000 l/h is designed for continuous separation of whole milk into cream and skim milk. The separator allows the purification of milk from impurities and milk mucus.

For more information, send us an email at sales@foodtechprocess.com

- Productivity: 1000 l

- Engine power, kW: 0,55

- Principle of operation: Continuous mode

- Weight: 71

- Voltage: 380-400V

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

The equipment is designed for centrifuging and separating different types of products and raw materials.

For more information, send us an email to sales@foodtechprocess.com

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The big bag dosing/discharge station is designed to dispense powder blends big bags with a weight of 30kg with a built-in fan.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price depends on the selected modifications and specific options

The plow mixer is often used in the food, pharmaceutical, and chemical industries for mixing and saturating powder products with liquid media in order to obtain a high-quality mixture.

- High intensity and quality of mixing, stirring

- Short mixing time and a high productivity

- Guaranteed repeatability and reproducibility of the product batches

- Gentle handling of the product due to the mixing device's special plows

- A large number of options to choose from to fit a specific product type

- Air Purge Seals

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 700l/ 1200l/ 1800l

- Voltage: 380-400V

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

For more information, please, send us an email to sales@foodtechprocess.com

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers. For more details and price, please email us at sales@foodtechprocess.com

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications.

For more information, send us an email at sales@foodtechprocess.com

- Heating: Steam

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350 l

The price is indicated without gastro containers

Use this all-stainless steel water bath for gradual heating or cooking. The device is equipped with a practical drain tap for easy emptying of the container and is suitable for use with gastronorm containers.

- Compact installation

- Simple controls

- Safe operation

- Wide range of applications

- Material: Stainless steel

- Principle of operation: Batch mode

- Voltage: 220-230V