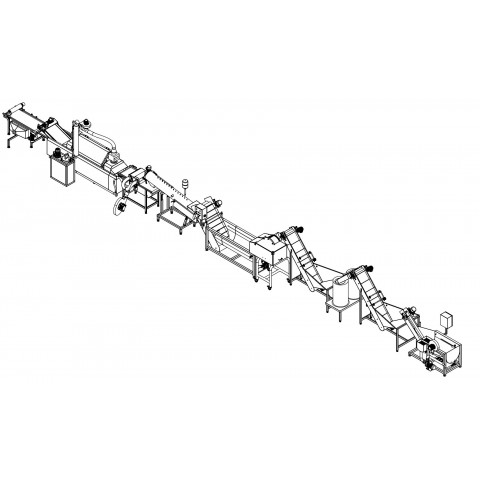

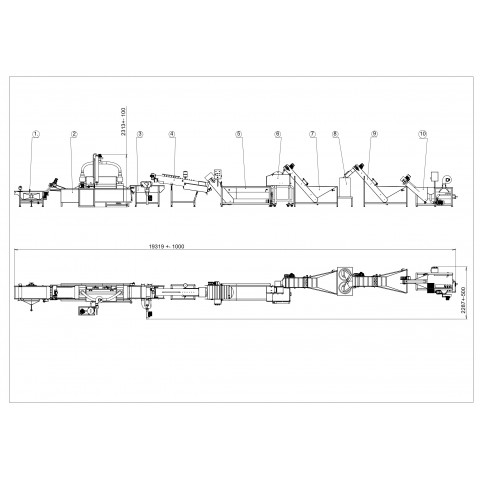

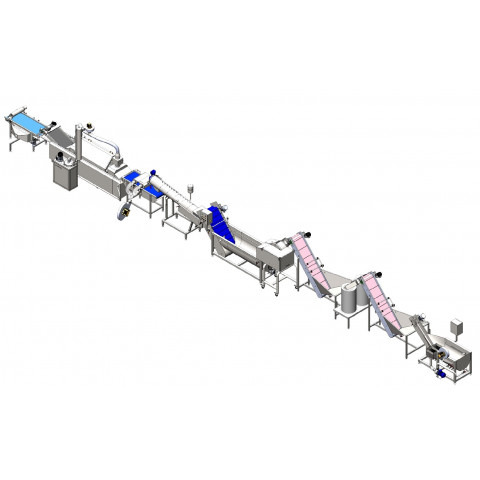

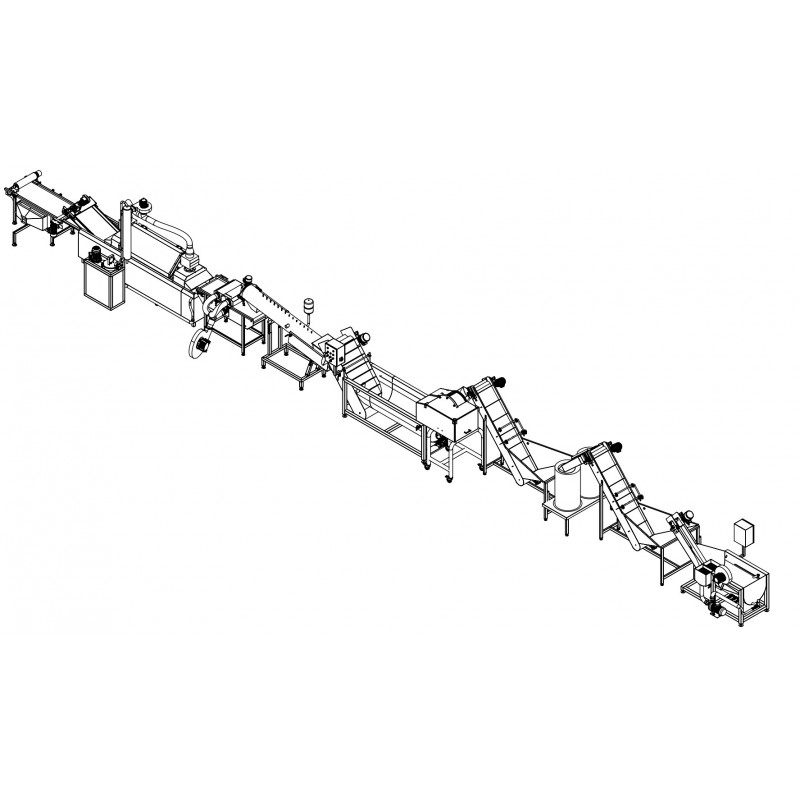

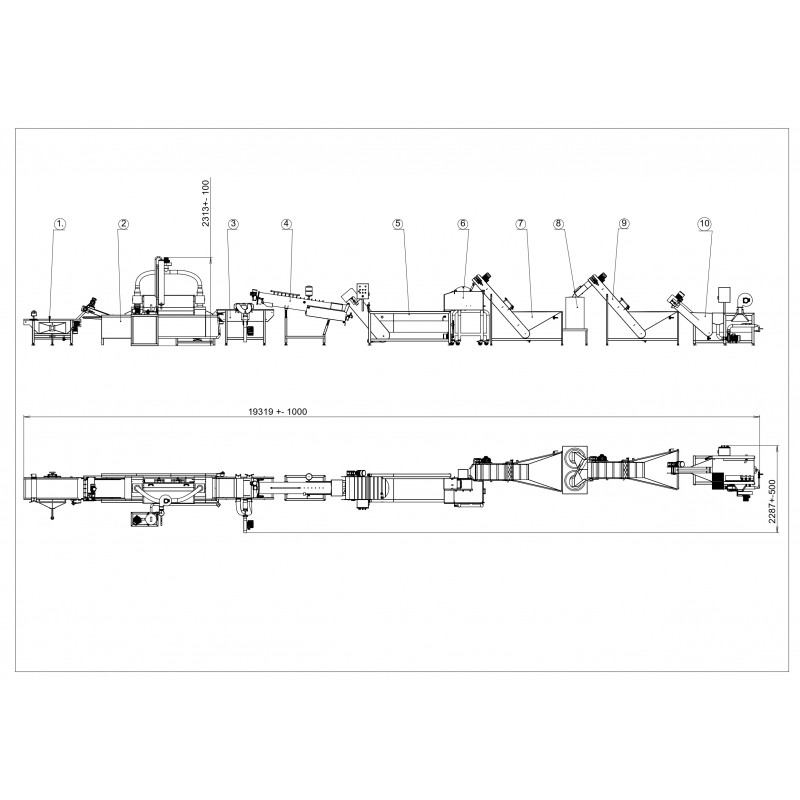

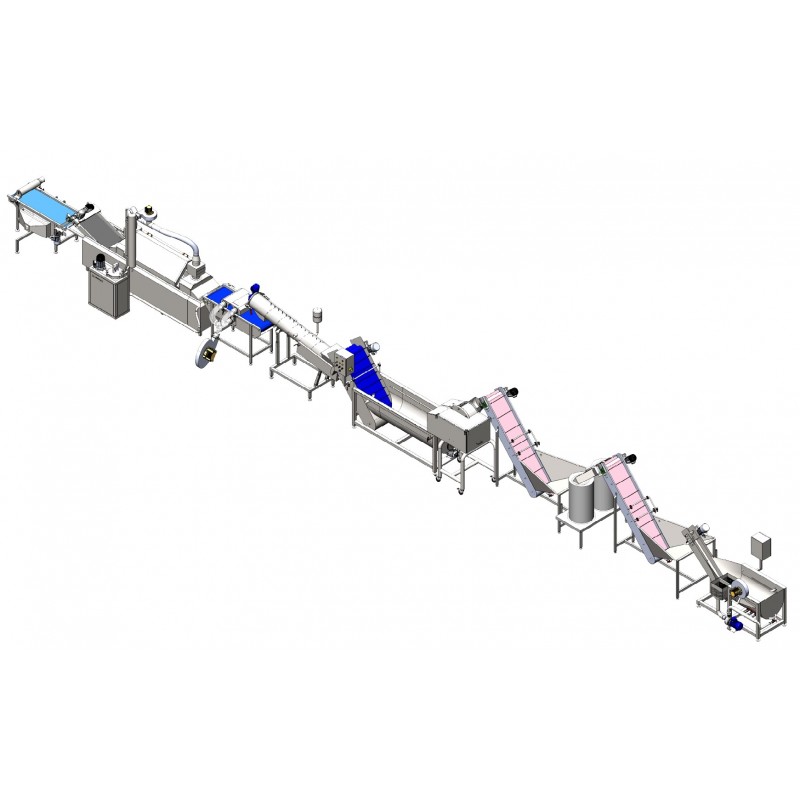

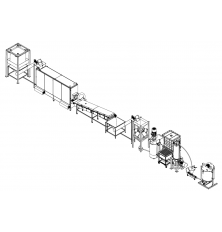

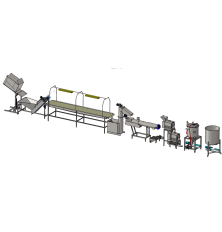

French fries production line

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

Equipment for the production of french fries and other potato snacks usually includes:

- Washing machine

Washing of root crops can be carried out in equipment with various different modifications and cost. It mostly depends on the degree of contamination of the potato or other root vegetables. We offer several drum type washing machines to choose from.

The simplest and most economical option is the drum washer with a remote conveyor. It is a drum set up at an angle with a drive for rotation, inside which a water irrigation system (shower device) and soft guide ribs are installed, with the help of which the product is gradually directed towards unloading. Due to the rotation of the drum, the potatoes are constantly turned over, the root crops rub against each other, being mechanically cleaned under the shower water flow. The washing principle is similar to the system used in drum washing machines. The inclination of the drum can be changed, thereby extending the time during which the potatoes will be washed in the working drum. The conveyor consists of a PVC sheet with remote blades, the slope of which can also be adjusted. It is recommended to include a frequency converter to adjust the speed of the conveyor.

Our offer also includes a drum-type brush washing unit, which is able to effectively clean the product without causing damage in the water flow due to the cylindrical rotating brushes installed along the entire length. This model is suitable for products such as young potatoes, when it is necessary to clean the tender skin, but where no further abrasive potato peeling is required.

For crops with minimal amount of contamination, a bubbling washer can also be used. It cleans the products using a bubbling system - supplying gas which is under pressure directly below the water level and creating a ‚Äúpseudo-boiling‚ÄĚ state in which the product is actively submerged under water, rotated and is subsequently fed in directed flows for unloading.

The next step includes the potato peeler.

Depending on the productivity, two parallel potato peeling machines can be installed, in which case it is necessary to install a feed separating conveyor to feed the root crops in parallel to each potato peeler.

- Abrasive potato peeler

The root crop, after getting into the working container with a stream of water, rubs through the abrasive walls and bottom, which polishes it, removing the peel layer. The size of the model is selected depending on the desired processing volume/productivity. It is always recommended to purchase additional abrasive spare parts for replacement. It is necessary to connect the the installation to a water supply and connect the outflow to the sewer.

After cleaning, the potatoes enter the receiving hopper onto the conveyor. It is recommended to install a conveyor equipped with a watering / rinsing system for the product.

- Potato cutter

The cleaned and washed root crop is loaded into the potato cutter with the help of a conveyor. The system cuts the product into strips safely and quickly with a constant supply, working continuously, and discharges it immediately into the rinsing machine.

- Rinsing machine

This equipment is necessary for a technological process such as washing out excess starch. The installation works as a washing machine with a turbulent water flow, which is created by means of an electric drive of the working shaft located inside the bath. The shaft is equipped with blades that not only create a flow, wash, forcibly lowering the product straws under the water level, but also advance it to the unloading point, where a belt conveyor is installed, carrying the chopped potatoes to the next processing section.

- Continuous blancher

After the starch is removed, the sliced ‚Äč‚Äčpotatoes enter the blanching section. The presence of this stage depends on the production technique, but even an ordinary cook always recommends boiling for 5-6 minutes before deep-frying, depending on the size of the chopped potatoes. This will reduce the time of subsequent frying and, accordingly, the over-cooking of the product (softening) and excessive saturation with oil. The blancher performs exactly this function during the continuous operation of the complex.

The blancher consists of an inclined working cylinder, inside of which an auger is installed, which advances the product inside. The unit is equipped with built-in electric heating for thermal oil. For proper operation, it is necessary to connect a water supply, and connect the waste water outlet to the sewer.

After blanching, the product is discharged into the drying section.

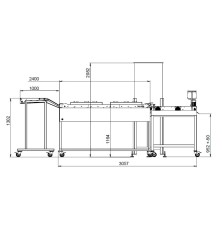

- "Air Knife"

It is a transporting conveyor with a PVC conveyor belt, above which 2 air knives are positioned at the top and one at the bottom for intensive directional airflow. This section is necessary to remove excess water from the product before loading it into the fryer.

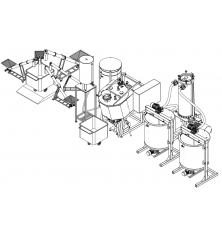

- Paddle fryer

The dimensions and heating power depend on the desired processing volume of a particular product.

The professional continuous paddle fryer is intended for frying potato chips, french fries and other root vegetable snacks. A defining feature of this model is the special blades installed along the entire length of the working bath, which carefully, without "sharp corners", dip the product into the oil, turning it over and moving it in the direction of the next blade so that the product is quickly, but qualitatively and evenly fried on each side. .

This type of fryer is used not only for french fries, but also for other types of snacks such as chips, which do not submerge themselves in oil, but float on the surface. The special shape and angle of the blades do not break or jam the product, minimal product losses, as special guides are located on the sides so that the product is guaranteed to be captured by the blades, turned over and moved towards the unloading point. At the end of the working container, a conveyor for lifting and unloading the product is located. Fast processing allows you to create a crispy crust without over-oiling the product.

The unit has electric heating, an oil filtration system, at the request of the Customer it can be retrofitted with numerous options, which include a vapor removal and filtration system, a recovery system, digesters, an automatic oil admission system and much more.

- Another "Air Knife"

After frying, the product is unloaded onto the conveyor, which is somewhat different in modification from the air knife used after the blancher, as it also has a bath underneath, into which excess oil flows from the product. Typically, one air knife is used, which is installed above the conveyor, which removes the oil from top to bottom with the directed movement of air as it falls into a container under the belt. For simple and convenient cleaning, a service hatch is installed on the side.

Depending on the requirements of the customer, the product can then be transported for freezing and packaging, or further processing.

- Principle of operation: Continuous mode

- Country of origin: Slovakia