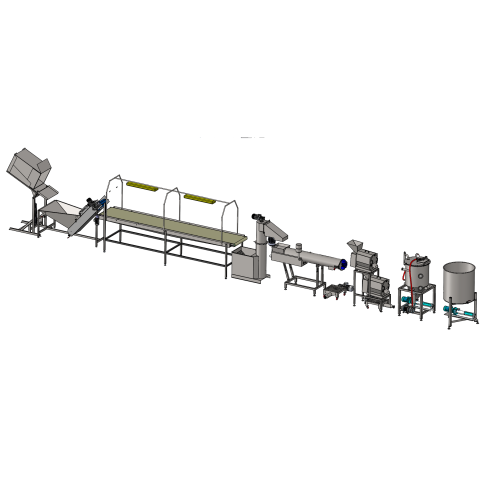

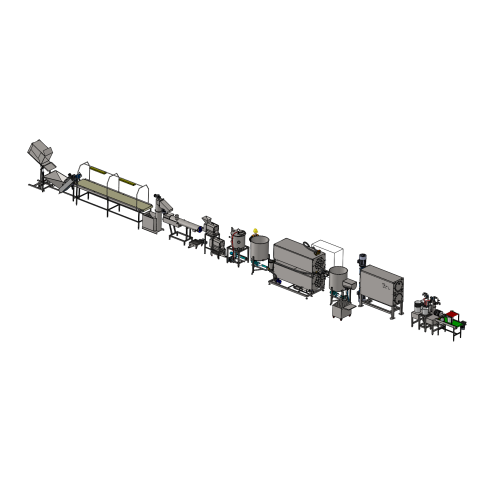

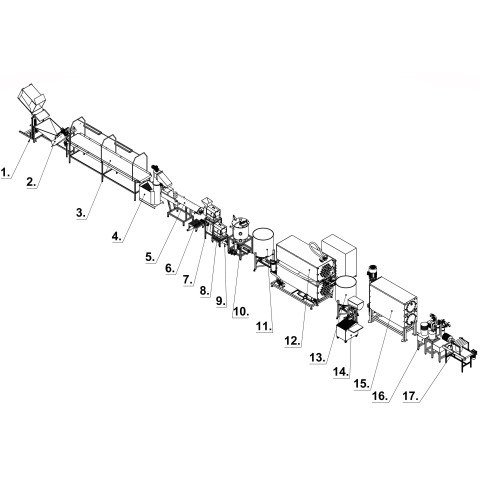

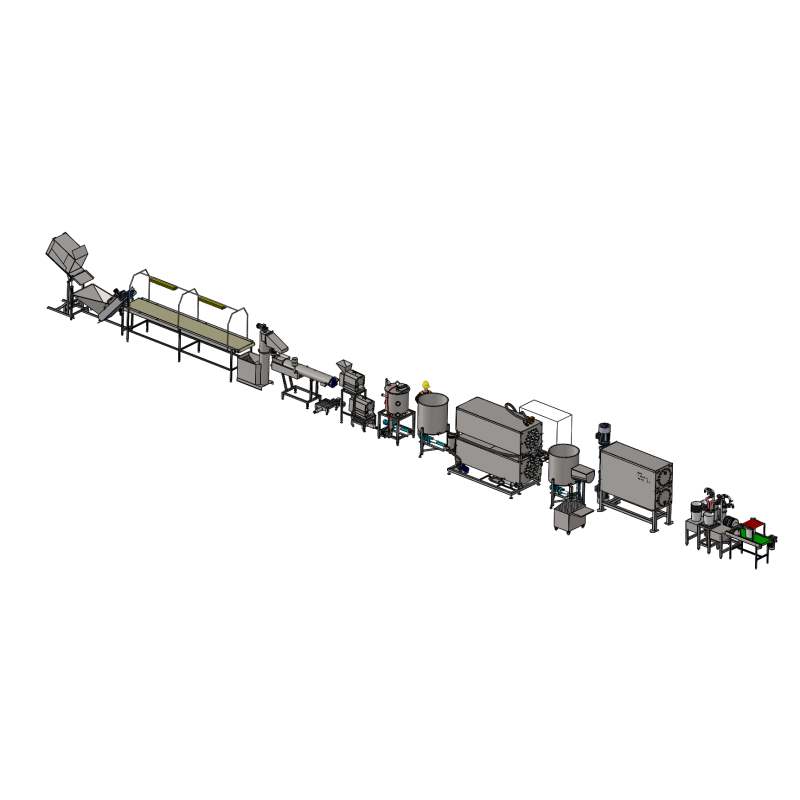

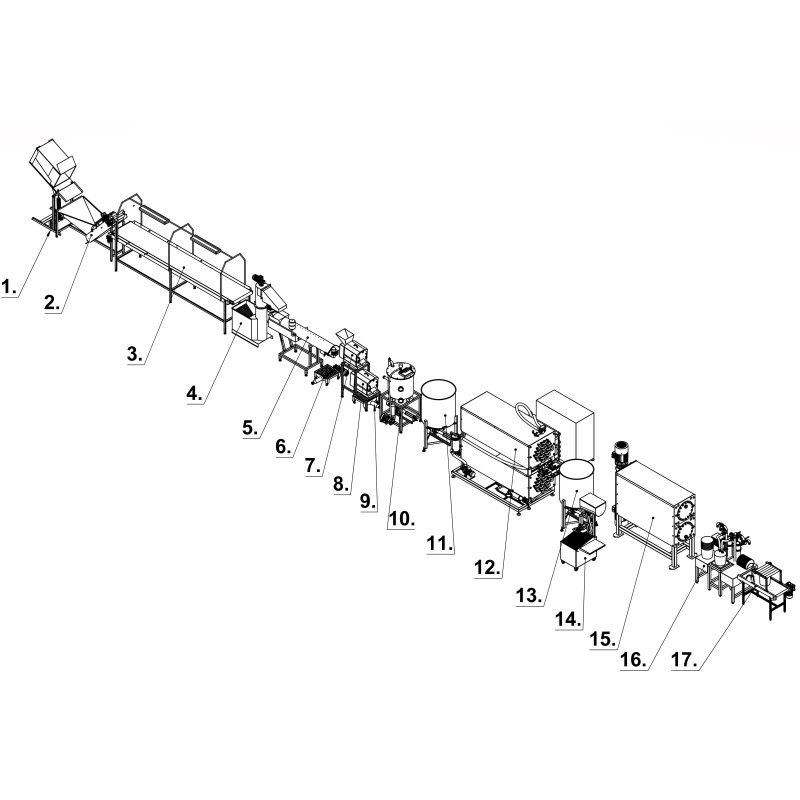

Apple puree production line

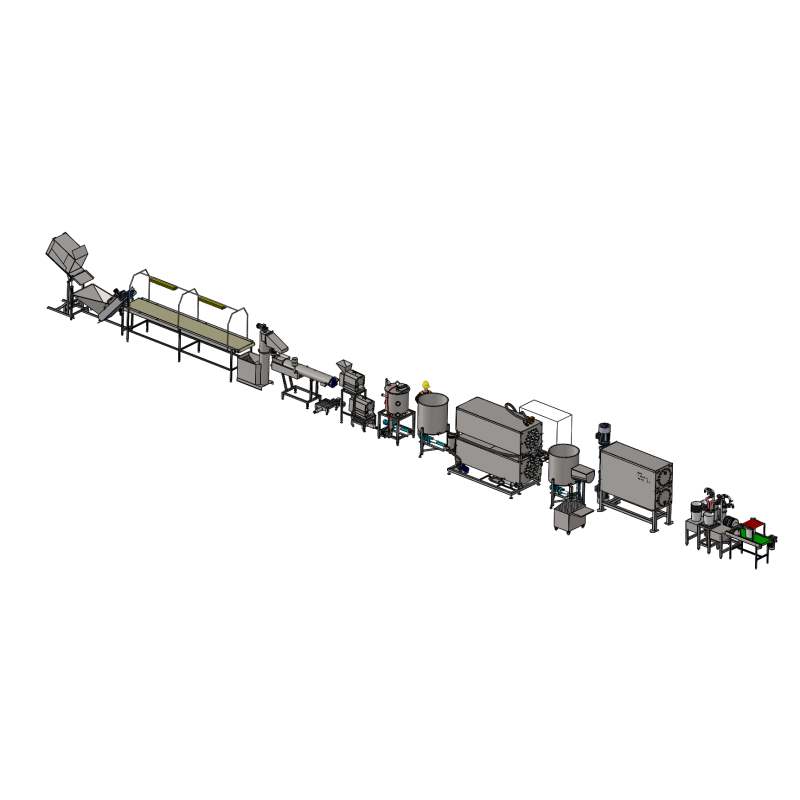

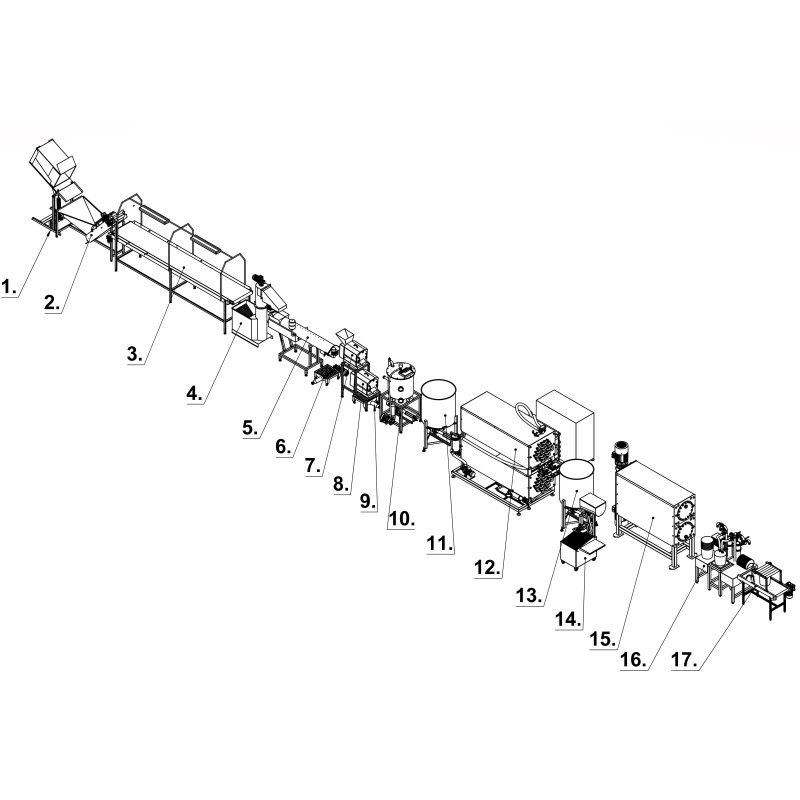

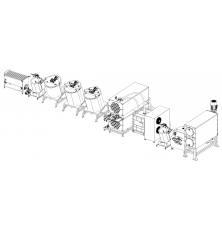

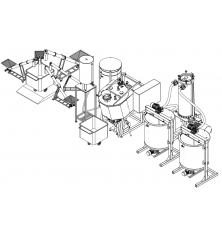

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

Applesauce is more than just a standalone product commonly featured in a wide variety of fruit-based baby foods; it also holds essential value as a natural component, especially in the production of heat-stable pastry fillings where pectin plays a crucial role.

The applesauce production line includes the following stages:

|

|

|

|

|

|

|

|

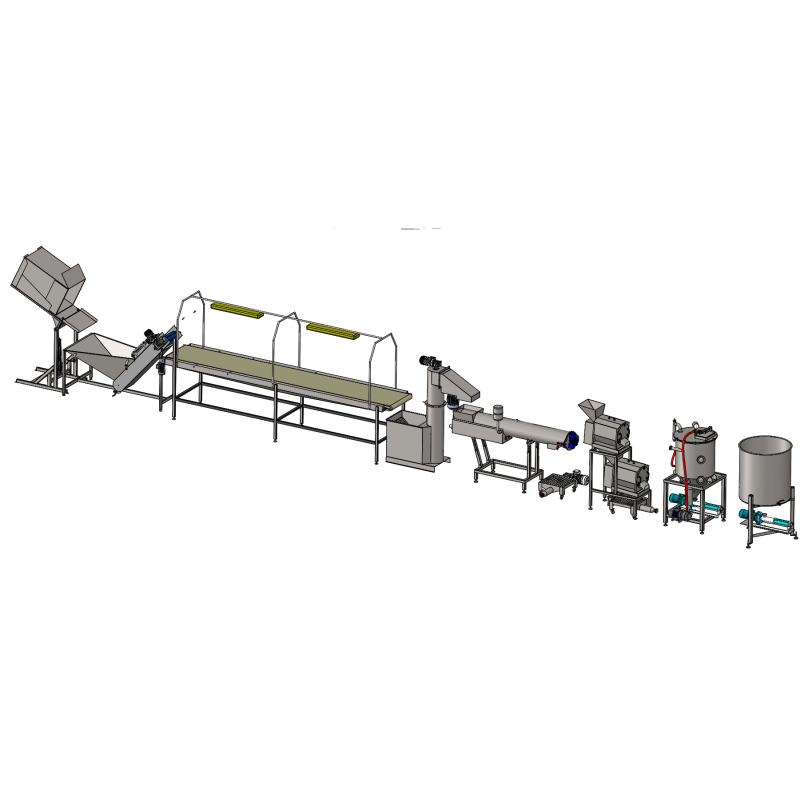

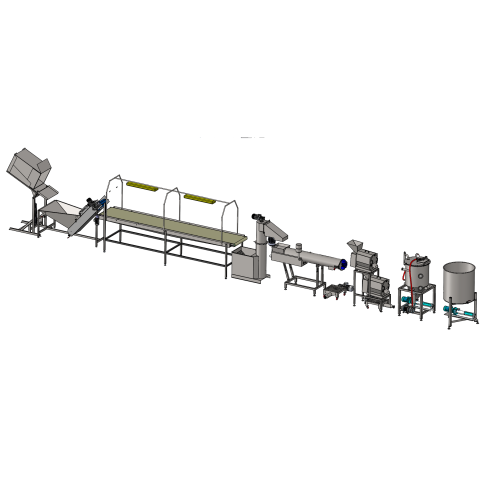

Basic version

Apples are loaded into the container of the tipping machine from various plastic or wooden boxes. The tipper is made entirely out of stainless steel and features an automatic hydraulic drive.

This is the first stage of processing, during which core fruits (apples or pears) are fed to the next section, which can be direct washing, inspection, or sorting. In this line for careful processing, the product is fed into a rinsing agent receiving hopper with a conveyor-lift (elevator).

Suitable for various containers with a maximum size of: 120x120x85.

The product is gradually unloaded (in small batches) into the rinsing hopper of the receiver, allowing for the regulation of the workload on the subsequent section - the inspection conveyor. This intermediate step ensures that the product remains undamaged due to its volume, weight, and dimensions, which is particularly important when processing ripe or even overripe raw materials as well as certain soft varieties of apples or pears. Once inside, the elevator lifts the product gradually in portions, with nozzles positioned above supplying water for showering and rinsing the product. A connection to the installation of a water supply source and sewage is necessary. The rinsing process effectively washes away and removes leaves, sand, and stones before unloading onto the inspection conveyor.

One of the most important stages after receiving raw materials is sorting and inspection. This process is usually performed mechanically by operators stationed on either side of the conveyor. The inspection table consists of a conveyor with a PVC conveyor belt, the speed of which can be adjusted using a frequency converter. Lighting lamps are positioned above the belt to assist operators during fruit sorting. The length of the inspection conveyor is determined based on the productivity requirements.

Following inspection, the apples undergo processing in a specialized vertical lift washing machine featuring an auger and a crusher, positioned at the equipment's outlet. This device operates in both continuous and periodic modes, equipped with a robust drive. Depending on the version, the installation may vary in height, incorporate a rotating tower for convenient cleaning, and offer various cutting sieves tailored to different fruit types and desired grinding fractions. This washing and grinding method is specifically designed for core fruits.

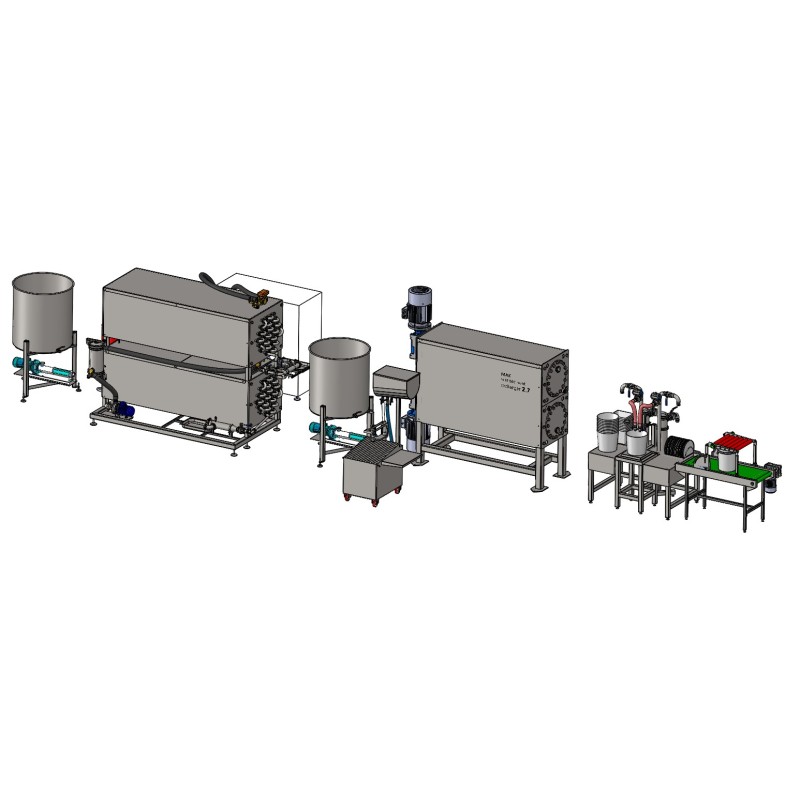

To enhance subsequent grinding and obtain apple puree, a blanching process is employed, softening the crushed apples and raising their temperature. This process occurs in a continuous screw blancher with direct injection of purified steam. The product, transported via a screw conveyance mechanism along the entire installations length, undergoes direct scalding with steam - an approach more effective than soaking and lessening raw material loss, as seen in the classic hot water blanching method. Steam imparts its energy to the product swiftly and intensely, softening it without excessive soaking.

The resulting mass is discharged into the receiving hopper of a specialized pump designed for thick products and fruit masses. This monopump can even handle whole berries, featuring a screw conveyor with a hopper and equipped with reverse functionality as well as a control panel.

Utilizing this pump, the softened fruit mass is directed to the destoning section - a process eliminating seeds, peel, and stalks. The production line employs a double destoning system, comprising a two-level installation with two sequential units. The rotor compels the fruit mass through a perforated sieve, separating pulp from the peel, seeds, and stalks. The fruit mass passes through the sieve and is ground into a soft puree. Sieve sizes are chosen based on the specific product, the replacement or washing of the sieve is performed easily. The installation is outfitted with level sensors for the puree storage tank.

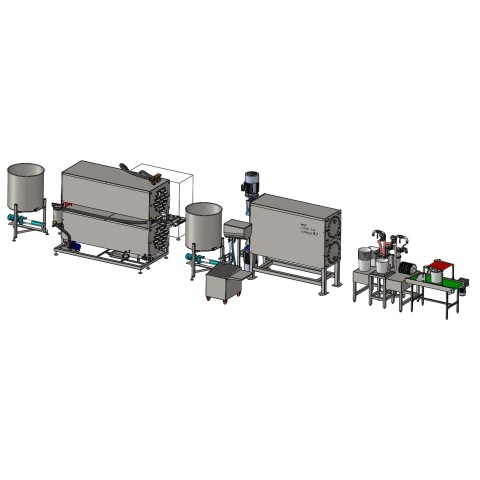

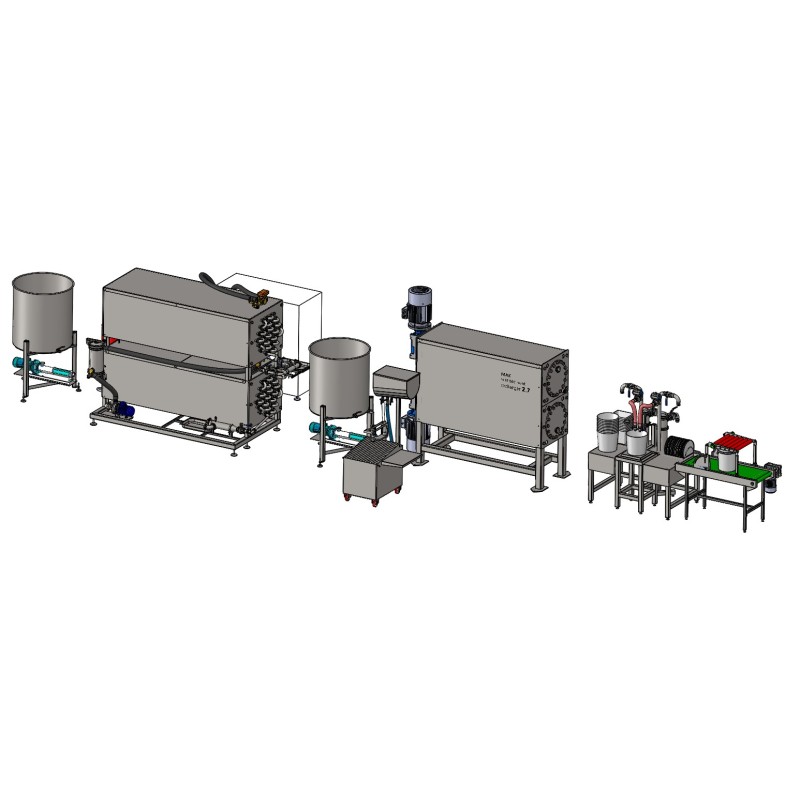

Using a special monopump with a hopper, applesauce is fed into the deaerator.

The continuous deaerator serves to degas applesauce, eliminating extraneous odors, preserving its natural color and taste, while also extending its shelf life and reducing the risk of oxidation. The installation features a vacuum system and a dedicated screw pump at the outlet. The installation can be retrofitted with sections of transparent inspection pipelines at the inlet and outlet for visual inspection. The maximum pressure in the vacuum chamber is up to - 0.8 Bar.

After the applesauce has been degassed, it is transferred to a closed buffer tank, which can be supplied with nitrogen to prevent air from being reintroduced into the fruit mass.

Additionally, the following features can be ordered as options:

- flow pasteurization section followed by cooling and Bag in Box filling

- flow freezing section with a dispenser for packaging in large containers (plastic buckets)

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Deaerator is used for the removal of air bubbles from the puree. Price depends on the required volume and production capacity.

For more information, send us a request.┬Ā

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

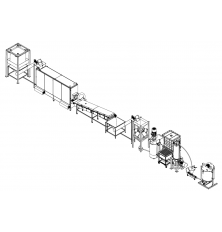

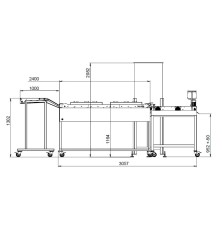

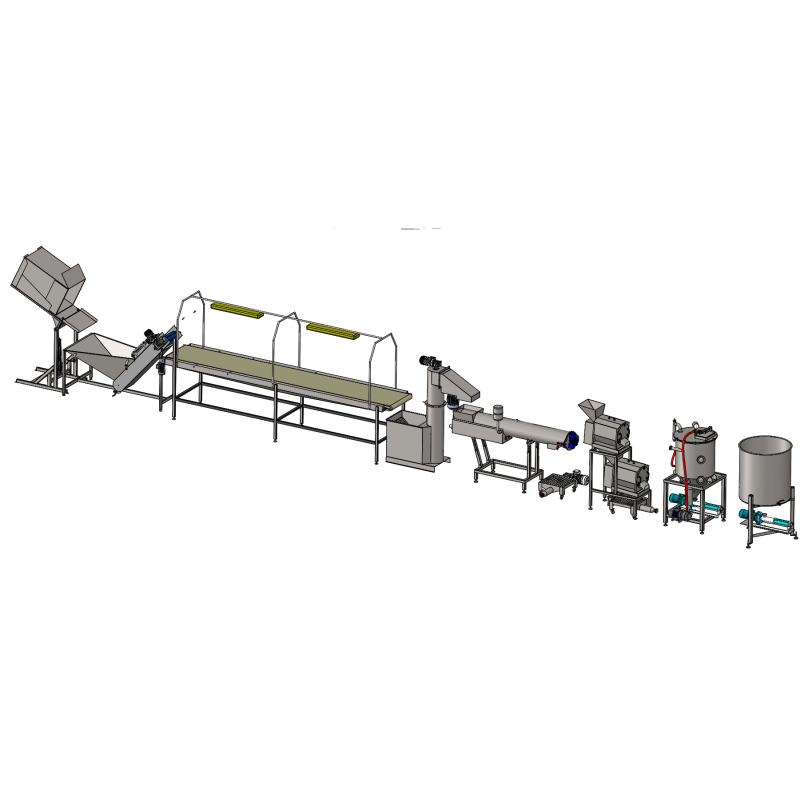

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk┬Āor┬Ānormalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode