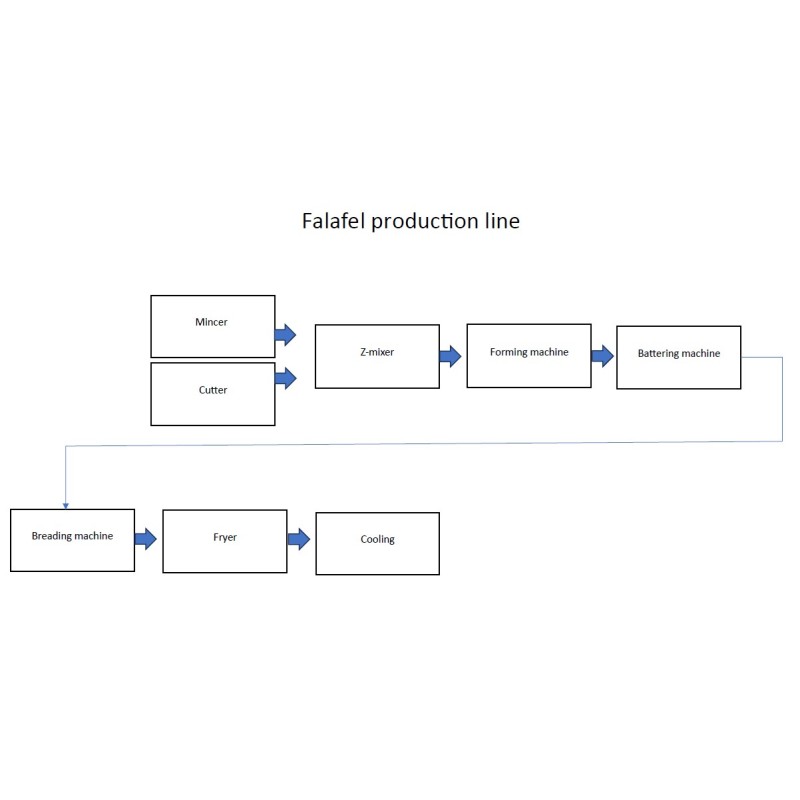

Falafel production line

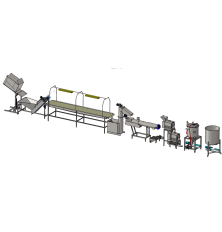

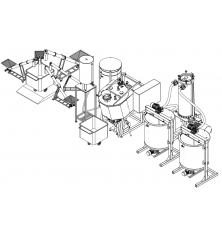

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

Plant-based products are now very popular not only in national cuisines, where various options of minced vegetables and their forms are widely used, but also in recipes from the vegetarian and vegan culture, as well as those focused on diet and nutrition.

The falafel production line can also be used to produce other vegan and vegetarian products such as:

|

|

|

|

|

The basic version of the line includes:

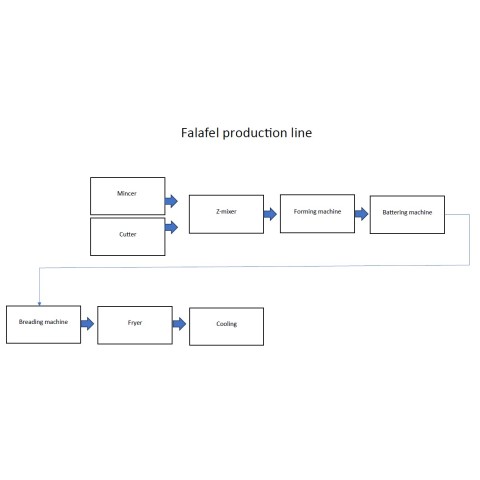

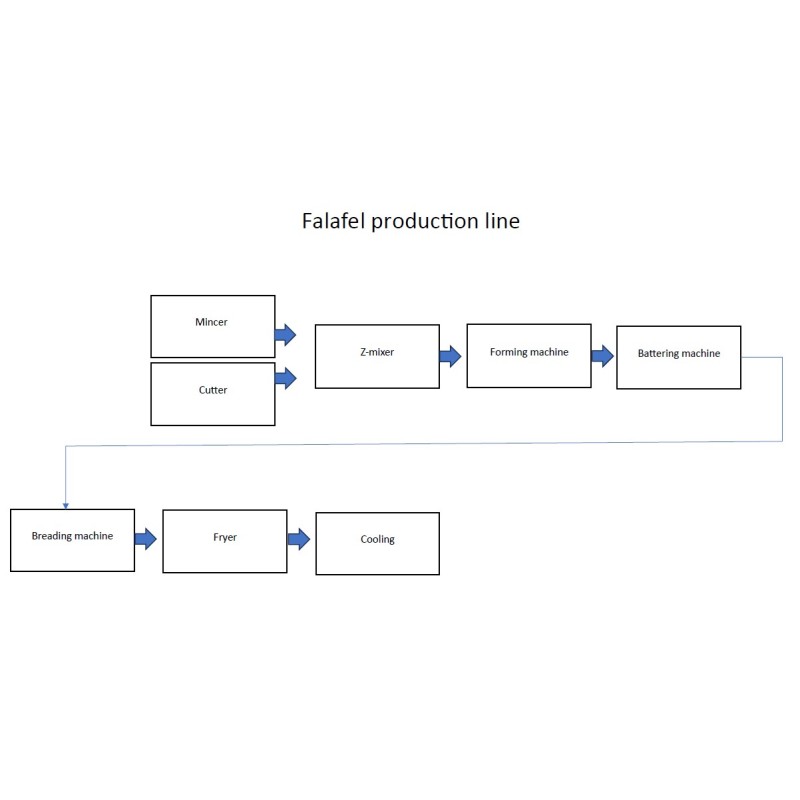

Vegetable, plant, and legume mass chopper

This is a versatile food processor, capable of continuous or batch grinding of fibrous masses, with the option to use various types of knives. The equipment's productivity is selected based on the required processing volume. The mixing unit is equipped with a wheel support featuring brakes for quick and convenient transportation.

Depending on the raw material being processed, the following devices may also be used:

Cutter for chopping soft vegetables and beans. This cutter features a robust electric drive for stainless steel knives installed in the lower part of the container. We also offer options with a rotating bowl.

After grinding, the product is fed into a Z mixer, equipped with Z blades on the shaft of the mixing device. The mixing device boasts a reinforced independent electric drive for each mixer shaft. This allows for the individual adjustment of speed and direction of rotation for each blade, enabling a customized mixing mode for each product based on its thickness and hardness.

Following the preparation of a homogeneous mixture of vegetable or vegetarian mince, the product is directed to the forming area. We offer various forming and molding systems. For falafel production lines, a former with round or oval shapes is typically utilized. These may include rotary press formers, which extrude the mince through a specialized molding matrix. The matrix is tailored according to the customer's product size. Forming machines are suitable for both denser products with fibers (such as meat and fish hamburgers, meatballs, and fish balls) and softer products (such as vegetable burgers, falafel, and potato-based semi-products). The advantages of the molding system include a wide variety of product shapes (round, conical, oval, or egg-shaped), shape retention and compliance with weight standards for each semi-product.

After molding, the products proceed to the coating/breading section. Depending on performance requirements, either small dry breading systems or combined wet and dry breading systems may be installed, based on the recipe. Breading machines feature a conveyor belt on top of which products pass through sections for dry, wet, and again dry breading, following the classic recipe for coating products in flour, batter, and breadcrumbs.

Automation and product transfer between sections are typically managed via conveyors, while in manual setups, equipment operators handle the process mechanically.

Post-breading, products can be transferred to the frying section, which may include a double-conveyor forced-immersion deep fryer or a pouring-type fryer with shallow oil frying. The choice of a suitable fryer depends on the desired degree of product frying. In industrial falafel production, the recipe usually calls for partial frying to seal the product's surface pores and to preserve internal juiciness, as the final baking is intended to be done by the consumer in ovens. Some technologies also utilize a combined heat treatment method, involving frying in oil and subsequent baking in continuous steam tunnels.

Following heat treatment, products enter the pre-cooling section before packaging/freezing. This section consists of a specialized enclosed conveyor equipped with multiple air knives and additional reserve connections for the cooling units. After passing through the pre-cooling section, which includes a built-in system for removing excess fat after oil-based heat treatment, products proceed to the freezing/packaging section for subsequent storage.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

You might also like

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

100 and 120 liter cutter mixers have been designed for the food industry, pharmaceutical industry and test labs.

- Productivity: 120 kg/h

- Material: Stainless steel

- Engine power, kW: 15/ 18

- Principle of operation: Batch mode

- Volume: 100l/ 120l

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

An automatic forming machine shapes food mixtures such as ground meat or plant-based alternatives into uniform portions. It automates portioning and shaping, and can also add a separation paper for easier handling before transferring the products with a conveyor. These machines reduce manual labor and increase output capacity for food processing facilities, butcher shops, and commercial kitchens.

- Material: Stainless steel

- Principle of operation: Continuous mode

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

The hamburger production line is designed for the production of hamburgers, veggie burgers or soy-based burgers. The line produces from 2.000 up to 6.000 hamburgers per hour. Price depends on the production requirements.

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Voltage: 220-230V

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

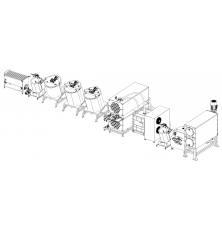

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

For the price quote or more information regarding this equipment complex for the production of chocolate, please send us a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk┬Āor┬Ānormalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

This jam production line allows you to get ready-made jam at the exit from whole fruits at the entrance! Equipment options may vary depending on the customer's technology.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU