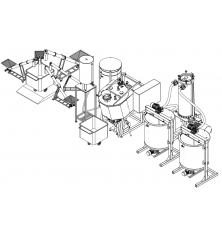

Chocolate production equipment complex CHOCO LINE

For the price quote or more information regarding this equipment complex for the production of chocolate, please send us a request.

Chocolate production line is an automated closed system for making chocolate, chocolate glaze and chocolate fillings.

The chocolate production line is intended for highly efficient production of chocolate fillings, chocolate mass, various types of chocolate glaze, nut and chocolate pastes (such as Nutella) and similar products.

How the chocolate is made

Melted fat, ground cocoa beans, sugar (powdered sugar), flavoring agents, and other ingredients according to the formulation are premixed in a mixing device. Next, the mixture is pumped through a heated pipe to a ball mill. After passing through a ball mill, the mixture is returned to the blender and the product is recirculated between the ball mill and the blender. During this product circulation process a high degree of homogeneity of the mixture is achieved and the particles are ground.

The construction of the homogenizer / emulsifier allows the free space between the rotor and stator to be adjusted and thus indirectly affects the particle size of the final product. The homogenization unit is equipped with a double mechanical seal with a separate lubrication and cooling system. Upon reaching the desired degree of grinding of the particles, the product is discharged by the pump through the ball valve discharge valve.

CHOCOLATE PRODUCTION LINE BENEFITS

- High quality equipment. The device is made of high quality stainless steel, which guarantees a long life.

- The device is hygienic and easy to clean.

- High quality finished product thanks to gentle processing and intelligent temperature control.

THE CHOCOLATE LINE CONSISTS OF:

1. Mixing vessel

with a melting grid in which all ingredients are pre-blended according to the recipe and pre-ground with a ball mill; The mixer consists of a vertical conical vessel with a gear motor, a chocolate line production line mixer with stainless steel scrapers and a melting grid. Pre-mixer with melting grid

2. Ball mill

serves to grind the raw materials using continuous spherical balls. The device consists of a vertical cylindrical vessel, a geared motor, a ball, a paddle stirrer and a double casing. After processing, depending on the technology, the product is transported to a mixer or to a container.

3. Storage tank┬Ā

container for storing chocolate glaze with jacket heating and low speed anchor stirrer with scrapers.

4. Heat exchanger

it is equipped with electric heating, circulation pump and piping.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

You might also like

The price is indicated without the control unit

The heat exchanger is designed for efficient and gentle heat treatment: heating and cooling liquid and pasty products, including those with a high viscosity, such as jam, chocolate, caramel, glazes, creams, marinades, baby food, honey, fish or meat stuffing and many similar products.

- Uniform thermal processing of thick and viscous products thanks to the supply of the coolant into the duplicator

- Efficient heat transfer due to especially shaped blades

- Continuous operation that does not allow the product to locally overheat or overcool

- Intensive heat transfer due to the internal mixing of the product with scrapers

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 250l/ 500l

- Voltage: 380-400V

- Heat transfer area, m┬▓: 2,7/ 5,4/

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

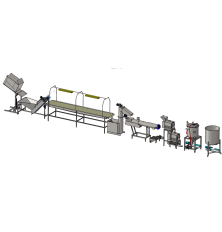

Automatic enrobing unit for the production of chocolate truffles.┬ĀFor more information, send us a request.

- Productivity: 50 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Working Area Width: 180 mm

- Voltage: 220-230V

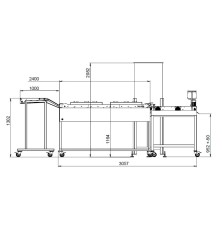

This machine is used to produce sweets coated with chocolate.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 7l/ 16

- Voltage: 220-230V

We offer equipment for processes such as: honey dissolution, honey drying, honey homogenization, honey pasteurization, honey creaming and honey packaging. The necessary equipment is selected by the customer based on the required processing technology for their manufacturing process.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

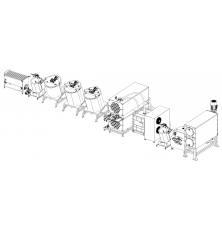

This equipment complex enables the production of Nutella-type chocolate pastes with a capacity of up to 250 kg/h.

- Material: Stainless steel

- Country of origin: Slovakia

A production line for making puree from seeded fruits such as apples or pears with a processing capacity of up to 2000 kg/hour of raw materials.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Croquettes production line for making and batter breading croquettes, preparing them for frying. Croquettes from 15 to 55 grams. Produces up to 12,000 pieces/hour. We also offer a range of fryers.

Price depends on your production capacity.

- Productivity: 12 000

- Material: Stainless steel

- Principle of operation: Continuous mode

The extended version of the modular conveyor fryer with a large number of optional accessories, significantly expands the production capacity for deep-frying various products by increasing both the frying area and heating power.

- Frying time can be adjusted from several minutes up to an hour!

- Overheating safety sensors are installed on each heating element

- Compact support structure on a mobile support

- Fine-mesh conveyor grid allows for frying small and fragile products

- A large number of additional options in the form of automatic oil top-up system, loading conveyor, filtration system, cooling conveyor, etc.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

The set of individual equipment for the production of French fries may differ depending on the initial raw materials. We offer various modifications from washing to frying with subsequent dehumidification starting from 50 kg/h for the final product.

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Meatball production line comprises of a filler, automatic machine for making meatballs and batter-breading machine. Price depends on your production capacity.

- Productivity: 15 000

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 220-230V

This set of equipment for the production of condensed milk from dry components by restoring the milk. This production line can be manufactured with a capacity of up to 500 kg/h or can be customized based on specific requirements.

- Material: Stainless steel

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

Production line for vegetarian vegetable-based formed or molded products such as falafel. The line is based on the classical method of producing semi-finished products for their subsequent freezing and packaging.

- Compact line suitable for both professional kitchens and industrial production.

- Fully automatic operation with minimal manual labor.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk┬Āor┬Ānormalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

A production line for thermostable fruit-based fillings, widely used in the production of pastries, baked goods, and various semi-finished products, as well as curd cheeses, creams, and even ice cream.

- Obtaining top-notch thermostable fillings while preserving essential nutrients and vitamins.

- Compact system featuring a unified control panel, ensuring easy and straightforward operation.

- Swift and efficient recycling included as a standard feature.

- Modular design with numerous additional options for customization.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The complex of equipment for the production of mayonnaise consists of several installations for automatic dosing, mixing, and obtaining a stable emulsion.

- Compact design, offering convenient and straightforward operation in a limited space.

- Cost-effective solution for automatic dosing without incurring high automation costs.

- A wide range of additional modular options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 13,5

- Voltage: 380-400V

This equipment set can be used for the production of a diverse array of sauces, as well as various vegetarian products based on nuts, soy and rice. It is capable of processing around 300/600 liters of product per batch.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 300l/ 600l/

- Voltage: 380-400V