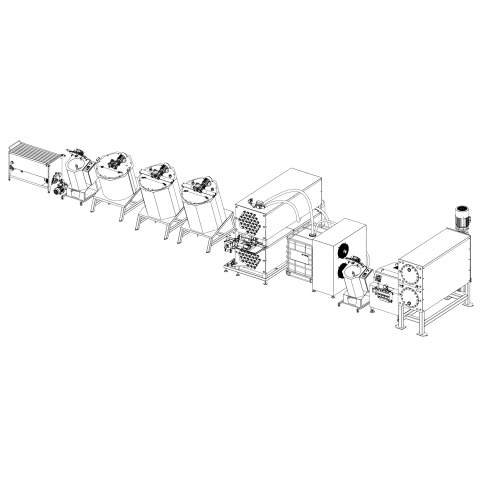

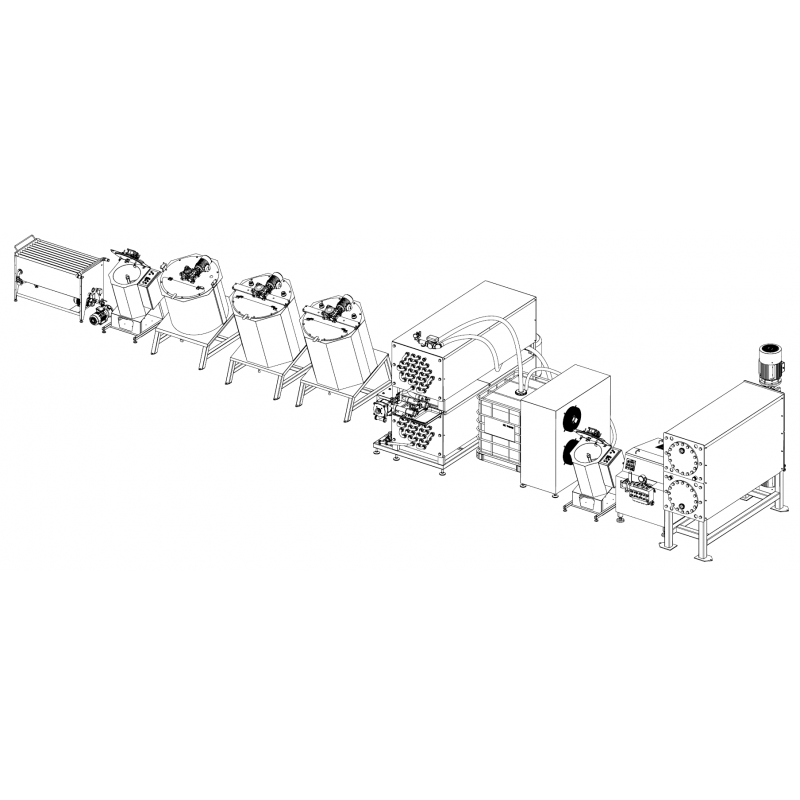

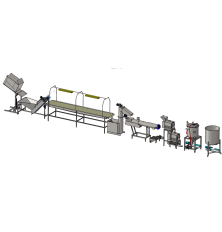

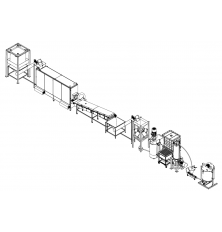

Margarine production line

A complete set of equipment for the production of margarine with a capacity of up to 500 kg/hour.

The complex of equipment for the production of margarine and other products on a margarine basis, comprises of the following equipment:

Melter - fat melter

Designed to melt frozen or hard blocks of fats of animal or vegetable origin and maintain them in a molten state at a given temperature. The bottom and walls of the melter are equipped with a heating jacket, hot water is circulated through the jacket, as well as the central grate.

A source of hot water is required (not included).

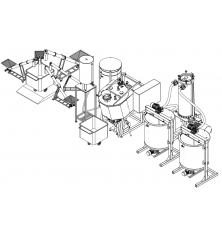

Fat phase mixer

Designed for mixing and the primary emulsification of fat phase components. It is an atmospheric unit with a working volume of 100 liters with a heating jacket and insulation, a mixing device. The basic version includes a temperature sensor in the product, soft-starter of the mixing device. A foot valve is already installed in the basic version! The unit can be retrofitted with CIP cleaning heads.

A source of hot water is required (not included).

Pump for feeding the fat emulsion into the emulsifier tank

Water phase mixer

Designed for mixing dry components in an aqueous medium and maintaining the temperature of the mixture at a given level. It is an atmospheric unit with a working volume of 430 liters with a heating jacket and thermal insulation, a mixing device. The basic version includes a temperature sensor in the product, soft-starter of the mixing device. The unit can be retrofitted with CIP cleaning heads.

A source of hot water is required (not included).

Pump for supplying the aqueous phase to the emulsifier tank

Emulsifiers with an external homogenizer

The emulsifiers have a remote Ultra Shear-type homogenizer-emulsifier to combine the fat and water phases into a stable emulsion. The tanks are used alternately to ensure the continuity of the process, while in one the emulsion is being prepared, from the other, the already prepared emulsion is fed into the pasteurization-cooling unit. Emulsifiers are atmospheric installations with a working volume of 600 liters with thermal insulation and a mixing device. The basic version includes a product temperature sensor, soft-starter agitator. The unit can be retrofitted with CIP cleaning heads.

Ultra Shear homogenizer for creating stable homogeneous emulsions and mixtures, 7.5 kW.

Pump for feeding the emulsion into the pasteurization-cooling unit.

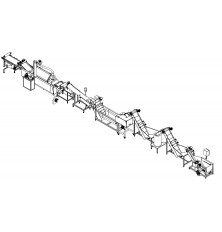

Pasteurization-cooling plant

For heat treatment and emulsion filtration in shell and tube heat exchangers, which increases the shelf life of the product. Hot water supply not included! An ice water station (chiller, buffer tank and refrigeration pump) must also be provided for the correct operation of the unit.

Storage tank (levelling)

It is an atmospheric container with a working volume of 100 liters made of stainless steel with legs.

High pressure pump

The plunger pump is designed for pumping the pasteurized emulsion into the scraped surface heat exchanger (cooler). The performance of the pump is regulated by changing the speed of rotation of the motor through a frequency converter. The outlet pressure of the product is also adjustable.

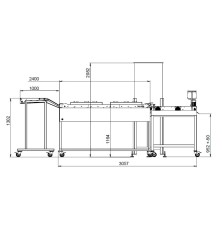

Scraped heat exchanger

For the implementation of heat exchange and the forced promotion of products of varying degrees of viscosity on the principle of translational-rotational motion of the rotor, equipped with special scraper blades, located inside the heat exchange tube with a cylindrical cooling "jacket". Two sections are installed on one frame: the first scraped heat exchanger for cooling and primary crystallization of the fat emulsion, above which is the second plasticizing section (finger processor) for intensive mechanical processing of the product in order to obtain a three-dimensional structure of the molecular lattice and ensure the plastic properties of the product.

Crystallizer

Designed for the final crystallization of the product to ensure its solid structure. Required in lines for the production of hard margarines and margarines for puff pastry. The dormant tube is a jacketed cylinder, which is internally equipped with baffles to slow down the passage of the product. The supercooled mixture from the scraped-off heat exchanger with the plasticizing section is sent to the resting pipe to create, mature the necessary crystallization structure into the mold (for structure maturation) and then to the forming equipment. It is recommended to install a "return" - a return before feeding to the packaging to maintain the required pressure.

- Type of the equipment: Part of a production line

- Country of origin: Slovakia