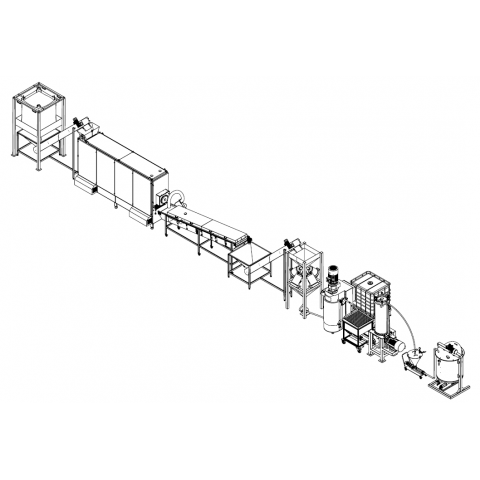

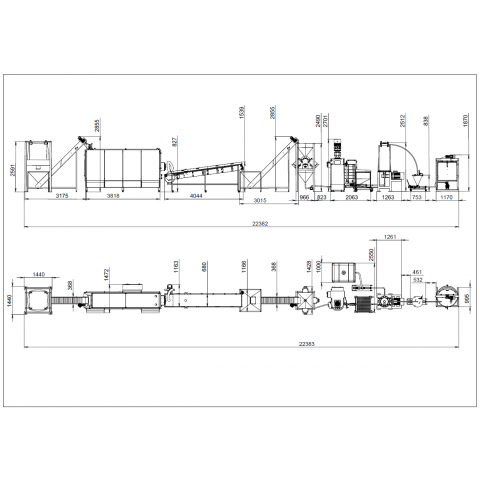

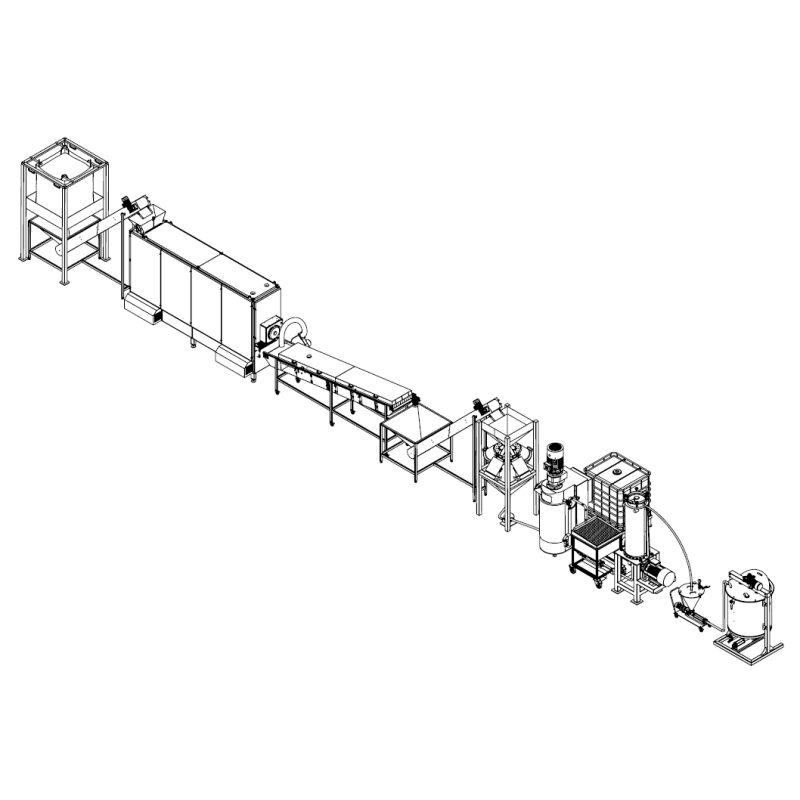

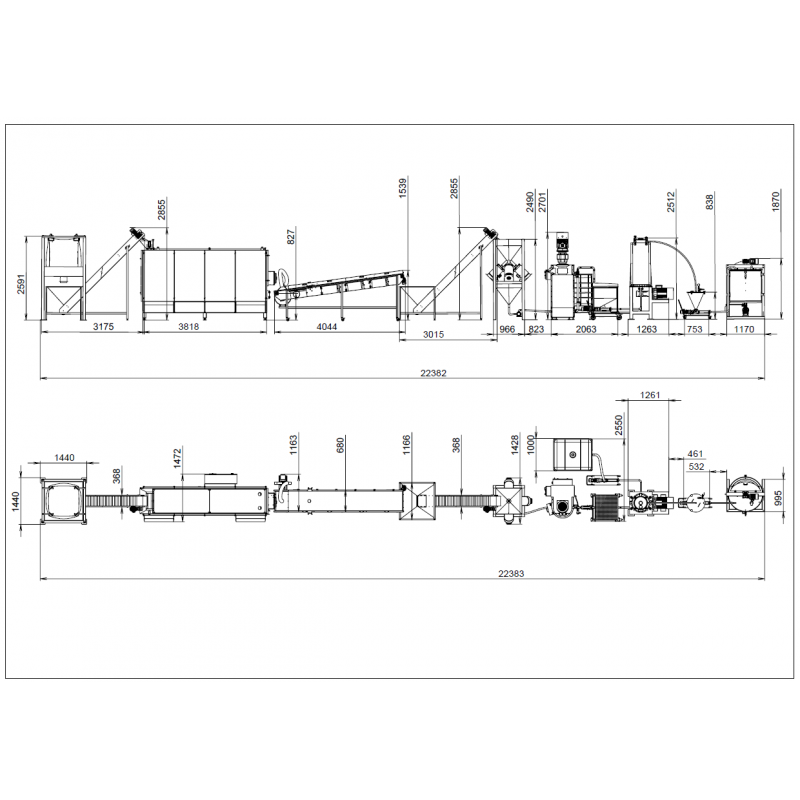

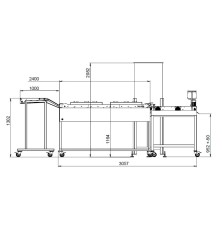

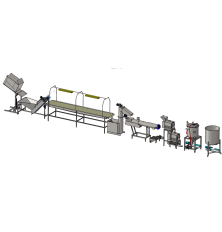

Peanut butter production line

An equipment complex designed for processing raw, peeled, and blanched peanuts, offering a production capacity of up to 500 kg/hour.

The complex of equipment is intended for processing raw, peeled and blanched peanuts to obtain completely finished peanut butter.

Includes processes such as:

- frying peanuts

- cooling

- grinding roasted peanuts in colloid mills

- homogenization of the finished mixture by grinding it into a particle size of 20 microns in a ball mill

- filtering

- deaeration of the finished paste to obtain a thick, tender mass similar to butter

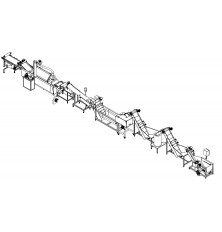

The unloading of raw materials is carried out using a special station - a big-bag unloader.

The unit is designed for unpacking bulk products packed in special big-bags of various sizes with a maximum weight of up to 1500 kg. A big bag is loaded into the container, under the pressure of its mass, the knife cuts the package, the raw material is poured out and accumulated in the receiving hopper of the conveyor. The grids located inside under the knife serves as a coarse filter to avoid getting big-bag particles or other foreign particles into the product.

Infeed conveyor for transporting bulk materials (peanuts) to the frying oven

A conveyor with a PVC working belt and a receiving hopper, designed to raise raw materials (bulk products) to the required height and load them into the oven. It is recommended to install a frequency converter to adjust the belt speed.

Continuous Multilevel Conveyor Infrared Oven DR7

The equipment can perform the following functions:

- drying / dehydrating

- baking / frying

of various products.

Equipped with 7 sections / levels of the heating zone, heating is carried out by heat emitters located above each conveyor. The product is loaded from above into the loading cone of the furnace, it passes through 7 heating sections located one above the other, where, passing from one section to another it turns over, which ensures uniform processing of the product. The product is then unloaded from the installation. The maximum heating temperature depends on the material of the working belt, it is recommended to choose a fine mesh stainless steel mesh for peanuts and similar products. The conveyor speed is adjustable from 20-50Hz.

The presence of an oven for the production of peanut butter in the complex is important in order to choose the degree of roasting of peanuts necessary in accordance with the recipe, which then affects both the taste, visual, nutritional and health properties of the product.

After unloading from the oven, the product enters the cooling conveyor

Designed to stop the frying process after heat processing in the oven, cools peanuts to room temperature before grinding.

The cooling conveyor is equipped with a PVC working belt, above which an air knife is installed near the ‚Äúentry‚ÄĚ for the product. The conveyor is also equipped with sidewalls, stainless steel top covers and special shutters at the inlet and outlet of the conveyor. Special openings are positioned below the level of the working conveyor belt for the possibility of connecting an additional cooling medium, which can also serve to remove steam.

After cooling, the peanuts are unloaded by means of a conveyor into the separating hopper of the grinding section.

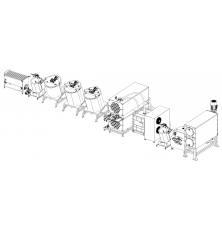

The separating hopper is designed for continuous and uniform feeding/loading of 4 colloid mills operating in parallel. It is made entirely out of stainless steel, the supporting structure is a two-level station, in the upper part of which is a divided cone, in the lower part there is a platform for installing and fixing colloid mills.

Grinding is carried out with the help of colloid mills

The colloid mill is a high-speed electric motor with a stainless steel shaft, where a rotor with a stator using special "teeth" / knives is mounted. A feature of the installation is the ability to adjust the distance between the rotor and the stator at three points, which allows you to choose the degree of grinding of the product. The plant makes it possible to produce not only smooth peanut butter, but also the "crunchy" type, which is distinguished by the fact that it contains small pieces of peanuts.

Colloidal mills are the main processing plant for the production of finished peanut butter from roasted peanuts. The remaining processes are mainly associated with the addition of various components, salt, honey, cream honey, stabilizers and thickeners to the finished paste. After grinding, if necessary to obtain a smooth oil structure, a ball mill can be installed. It is used in the production of chocolate, chocolate spreads and other similar products to achieve a uniform homogeneous mass with a fraction size of up to 20 microns.

The installed capacity options of the colloid mill are 7.5/11/15 kW.

Ball mill

The device consists of a stainless steel container with a specially shaped electric stirrer. The frame mixer has a shape similar to a pin mixer for thick and viscous products. Stainless steel agitator shafts, similar to "fingers", are arranged spirally or crosswise along the entire length of the agitator shaft, they can be replaced when abraded after prolonged use. Grinding of the product inside the container is carried out due to the movement of steel balls rubbing them together.

During processing, the temperature of the product rises by several degrees, so the working capacity of the plant is equipped with a coolant duplicator for cooling down, up to 0.5 bar. The "jacket" can also be used for supplying thermal water and heating the walls of the tank for better product unloading when processing high-viscosity raw materials. Working container material - AISI316Ti with titanium.

- Volume - 200 l

- Ball diameter - 6 mm (not included in the delivery, but can be ordered separately).

- When loading the mill at 1/3, about 350-400 kg of balls are loaded, when loading 1/2, about 550-600 kg.

The product is fed into the tank from below by means of a screw pump and exits through the top pipeline. It is recommended to retrofit the unit with a frequency converter for soft start and speed control of the agitator.

An obligatory step after processing the product in a ball mill is filtration

When unloading from the ball mill, steel balls may remain in the product, which must be filtered through the vibrating table.

The vibrating table is equipped with a special sieve on the upper body of the table, through which the product coming out of the upper pipeline of the ball mill flows. To ensure that the product does not accumulate in a heap, does not stagnate on the surface of the table and flows better through the sieve, the unit is equipped with a vibration drive. In the lower part there is a cone from which the product flows into the screw pump and with it's help, is subsequently transported to the mixer.

Continuous mixer

Based on the tests for this set of equipment carried out in our manufacturing facility, a natural peanut butter recipe was chosen, which does not contain artificial additives, emulsifiers and stabilizers, only two additional components are added to the finished paste: sea salt and cream honey. Sea salt is usually added during the process of grinding roasted peanuts, or into a mixer where cream honey is also added. Cream honey is supplied from an external container using a screw pump, the delivery rate of which is controlled by a frequency converter.

The peculiarity of cream honey is that it is a natural sweetener, which also has the property of a thickener when mixed with peanut butter, its shape makes it possible to guarantee the uniformity and homogeneity of the mixture, since cream honey does not crystallize. Peanut butter and cream honey are mixed in-line in the flow, where with the help of a screw pump, the paste is transported into a pin mixer.

After mixing the mass with all the components, it is recommended to deaerate the finished paste

Vacuum deaeration makes it possible to create a denser mass by drawing out excess air bubbles from the product and thereby extend the shelf life of the product. After processing in a deaerator, peanut butter is fed into a buffer tank for subsequent packaging using a screw pump for thick and viscous products. The customer's accumulator can be used, if long-term storage is required, it is recommended to choose a buffer tank with a "duplicator" for coolant up to 0.5 bar in order to keep the product in liquid form for easy unloading and dosing.

Piping, the degree of automation of the equipment complex control is requested additionally.

- Productivity: 500 kg/h/

- Principle of operation: Continuous mode

- Country of origin: Slovakia