Fruit and vegetable juice tanks 750 L - 5000 L

These storage tanks are intended for fruit and vegetable juice storage and treatment. Price depends on your production process and the product.

For more information, send us a request.

These storage tanks are intended for fruit and vegetable juice storage and treatment.

The tanks for storing fruit juices are suitable for containing the juice under atmospheric pressure to preserve its organoleptic features. They guarantee the utmost hygiene, reliability, practicality in use, safety and durability

JUICE STORAGE TANKS - MAIN FEATURES:

- Entirely made of stainless steel.

- Round upper door 400 mm.

- Washing unit on the top.

- Oval side doors at the bottom.

- Total outlet at the bottom.

- Side pumping outlet at the bottom.

- Sampling cock in the middle.

- Sampling cock at the bottom.

- Digital thermometer.

- Level glass tube.

- Looking glass pipe on the outlet.

- Glass integrated on wall of the tank.

- Rotating decanter valve for pumping.

OPTIONS:

- Cooling jacket,

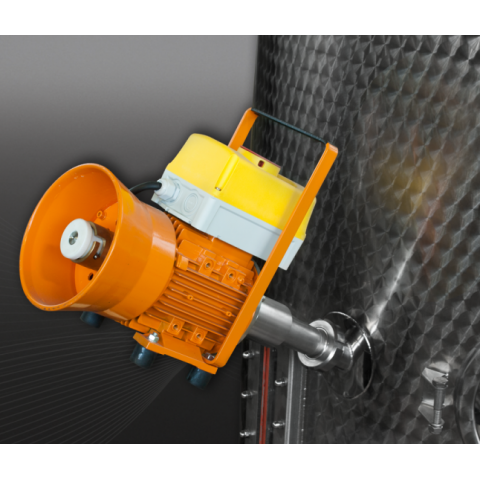

- Connection for mixer/agitator.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 750 1000l/ 1500l 2000 2600 l/ 3000 4000 l/ 5000 l

You might also like

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

The hot water tank is designed to catch the preheated water from the first stage of the wort cooling and then heat it to 80 ┬░ C, the pump bowl is a part of the vessel.┬Ā

- Material: Stainless steel

- Type of the equipment: Individual machine

- Volume: 2000

Pneumatic fruit presses are intended for smaller winemakers who want to produce high quality wine. Price depends on your production parameters.

- Material: Stainless steel

- Principle of operation: Continuous mode

The mill is designed for milling whole fruit or vegetable before further processing. Price depends on the chosen fruit and production capacity.

For more information, send us a request.┬Ā

- Productivity: 6000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

The cooling tank is designed for storing milk and other beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

It is possible to order tubs with four perforated walls and bottom, with or without outlet drain or with a tap.

- Material: Stainless steel

- Volume: 120l 200l/ 300l

The vacuum crystallizer-cooler is specifically designed for sweetened condensed milk. Crystallization with cooling is one of the most important stages in the production of condensed milk according to GOST and is necessary before dosing and packing the finished product.

- After crystallization, condensed milk has a delicate structure with small crystals

- Condensed milk has a homogeneous shape and attractive consumer properties

- The shelf life of condensed milk is extended without changing the quality of the product

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Tilting bratt pans with mixer are frying the product with continuous stirring. Designed for catering industry, school kitchens, restaurants and food industry. Variants of heating systems: direct electric and direct gas. Capacity: 150, 200 or 300l.

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 42

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 150l/ 200l/ 300l

- Voltage: 380-400V

The cylindrical conical tank is a designed for the fermentation of the beer and other beverages.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

A vacuum distillation system is used for controlled separation of liquids based on the evaporation of the liquid and subsequent condensation of its vapors.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 5l

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Open fermentation vat / vessel is designed for fermentation of beer and other liquids.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The atmospheric tank with an inclined design is used for mixing, stirring, and dissolving various products. By supplying a thermal carrier to the unitŌĆÖs jacket (duplicator) from an external source, thermal processing such as heating or cooling can occur (i.e. heating or cooling from an external coolant source with an inlet pressure of up to 0.5 bar). These units are widely utilized in the food and cosmetic industries.

- Inclined design: 50% more efficient mixing

- Due to the inclination angle of the working tank, rapid and complete (100%) emptying is achieved.

- Efficient heat transfer through the heating/cooling jacket

- No dead zones during mixing!

- Modular system with a wide range of additional options

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Working volume: 100l/ 200l/ 300l/ 450l/ 600l/ 900l

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l