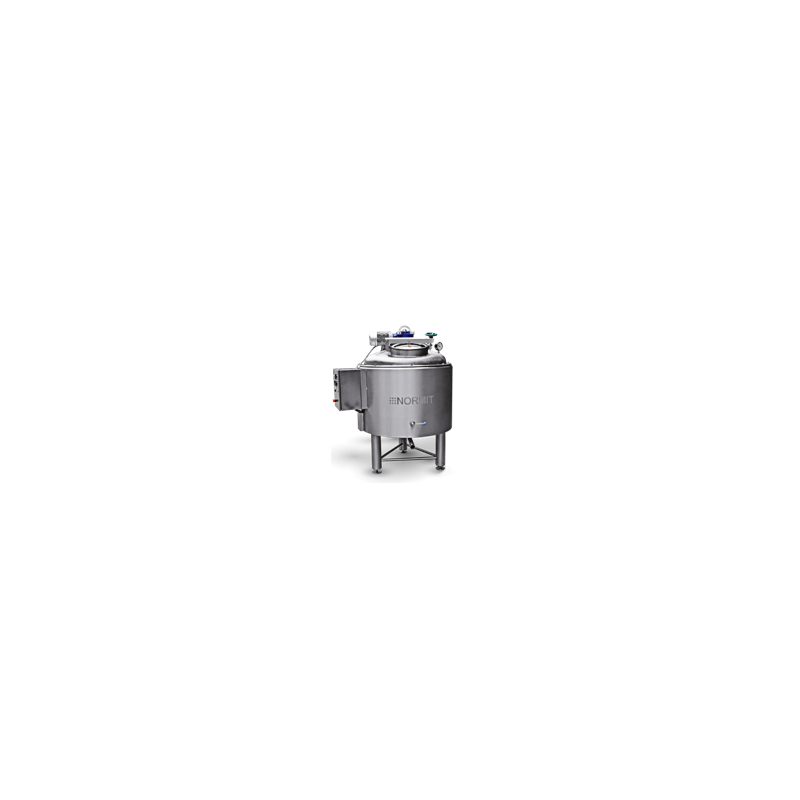

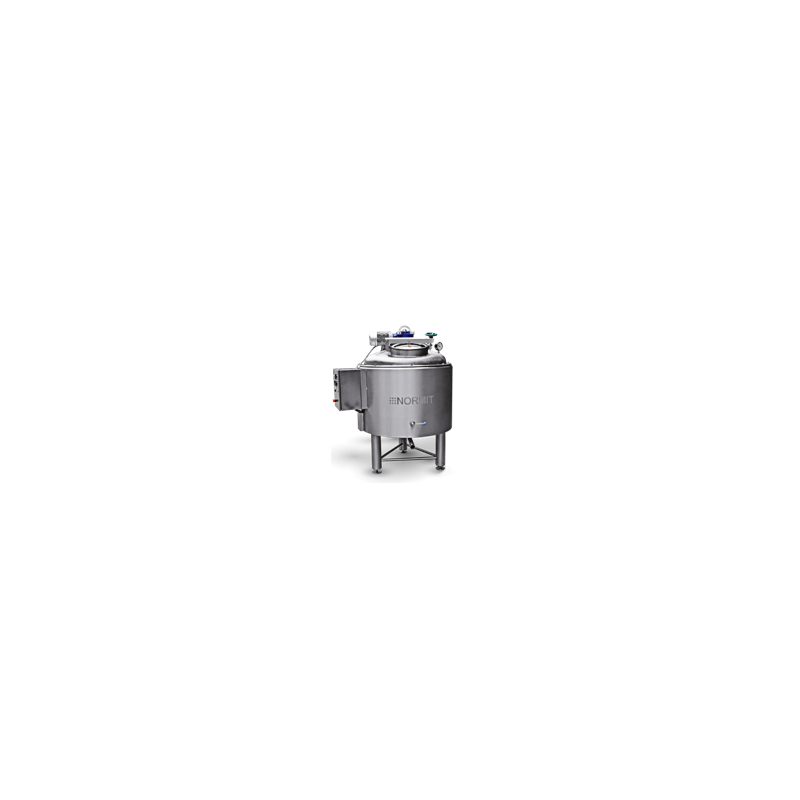

Vacuum cooker VC 300

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.Ā

The vacuum cooker is used for heating, cooking and mixing a wide range of products.

Technical details:

- Total volume: 350 l

- Working volume: 300 l

- Heating: electric

Applications:

- Jelly candies

- Jams

- Marmalades

- Syrups

- Sauces

- Creams

Design

- Boiler consists of double jacket with insulation, heating is provided by heating elements. The boiler is equipped with two temperature sensors, an oval manhole and an analogue vacuum manometer.

- The boiler contains a vacuum unit which generates a vacuum. The vacuum unit ensures better efficiency by reducing the boiling point of the fluid, thereby requiring less heat and less power for heating.

- The plant consists of individual vacuum cooking chamber in which the product is alternately cooked, which ensures an uninterrupted supply of the cooked mass to the dispenser. Components are loaded by means of a vacuum through a hopper set at a convenient height, which makes the operatorās work much easier and removes any need for additional lifts or tippers.

- The special design of the cooking chamber ensures ideal cooking, moisture removal, mixing, and dissolving of all ingredients.

- The cooking chamber are equipped with a specially-designed agitator with individual scrapers, which continually and effectively clean the inner walls of the chamber of any product, does not allow burning, and ensures even heating through the entire volume of product.

- The vacuum-cooking product allows removing excess moisture with low energy costs, and it ensures the color, taste and smell of the product are retained to the greatest possible degree. The lower cooking temperature in a vacuum allows you to use heat-sensitive ingredients in cooking, and you can also prepare confectionery where you donāt want sugar to caramelize and change the color.

- The cooked mass is unloaded by means of a pump.

Advantages:

- High product quality is ensured due to fast cooking at low temperature. The color, taste, and smell of the product is preserved.

- Effective mixing and dissolving, a small amount of additives are uniformly distributed through the entire volume of product.

- There are no dead zones that donāt get mixed, and heat is applied evenly.

- Components are conveniently loaded from the working platform by means of a vacuum.

- Itās easy to unload the ready product with a pump (or another variant at the customerās request).

- Itās affordable and has low maintenance costs. It uses the least possible energy for cooking the product.

- The model is complemented by a vacuum sample valve that allows you to taste the product during cooking without losing the vacuum pressure.

- Included is also the dosing table, which allows you to add various ingredients to the cooking process.

Features:

- The plant is manufactured entirely from AISI304 stainless steel for the food industry and has stainless steel scrapers.

- The cooking chamber have a specially-designed shape for optimal cooking.

- It features improved specially-designed scrapers.

- Itās compact ā all parts are optimally located within a small amount of space, and the layout is convenient for operators.

- Itās hygienic and can be easily cleaned by connecting to a CIP system. There are no areas where product can accumulate or which are inaccessible for cleaning.

- Steam, electrical, or gas heating.

- The vacuum generator is included in the set.Ā

Advantages:

- High product quality is ensured due to fast cooking at low temperature. The color, taste, and smell of the product is preserved.

- Effective mixing and dissolving, a small amount of additives are uniformly distributed through the entire volume of product.

- There are no dead zones that donāt get mixed, and heat is applied evenly.

- Components are conveniently loaded from the working platform by means of a vacuum.

- Itās easy to unload the ready product with a pump (or another variant at the customerās request).

- Itās affordable and has low maintenance costs. It uses the least possible energy for cooking the product.

- The model is complemented by a vacuum sample valve that allows you to taste the product during cooking without losing the vacuum pressure.

- Included is also the dosing table, which allows you to add various ingredients to the cooking

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

You might also like

Heating boilers are designed to cook sausages, hams and oļ¬al. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.Ā

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110Ā° ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.Ā

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as aĀ vacuum evaporator, aĀ vacuum cooking kettle, and aĀ unit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer āsandwichā base, allowing the heating temperature to reach up to 200 Ā°C.

- High processing temperatures of up to 200 Ā°C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110Ā°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Industrial kettle for cooking and stewing meat, vegetables, seafood, legumes, cereals under pressure up to 0.5 and temperatures up to 110 Ā°C bar.Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 600 l

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l