Washing tank with a belt conveyor and mill EWT

Washing tank with wheels with conveyor belt for fruits and vegetables.

Washing tank with wheels with conveyor belt and mill for fruits and vegetables.

VEGETABLE WASHER - TECHNICAL FEATURES:

- Made of AISI304 stainless steel

- Valves and fittings in stainless steel AISI304 / AISI316

- The frame is equipped with wheels with brakes for handling┬Ā

- Conveyor Belt with a useful width of 330 mm made of suitable material for contact with food-stuff

- The Conveyor Belt is powered by a variable speed gearmotor

- Discharge pipe for the overflow of the washing tank level┬Ā

- Rinsing shower for a better cleaning of the product

- Circulation pump for the water handling into the tank

- The washing tank is equipped with a perforated inferior sheet-metal for the receipt of the product

- The Conveyor Belt and perforated sheet-metal are easily extractable for quicker and easier cleaning and maintenance operations

OPTIONAL: Kit air bubbling system

FRUIT WASHER - TECHNICAL DATA

- Dimensions LxWxH┬Ā 2980 x 960 x 2050 mm

- Loading Tank┬Ā ┬Ā ┬Ā ┬Ā ┬Ā 1470 x 800 mm

- Unloading Hopper┬Ā ┬Ā 200 x 410 mm

- MIll┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā ┬Ā2.4 kW

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

- Productivity: 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

Semiautomatic production line for washing and destoning apples. Approximate capacity 1000 kg/h.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

This machine is suitable for washing fresh fruits and vegetables. We offer 2 different capacities.

- Productivity: 1000 kg/h/ 3000 kg/h

- Material: Stainless steel

- Engine power, kW: 0,55/ 0,75

- Principle of operation: Continuous mode

- Voltage: 380-400V

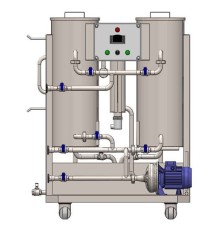

CIP-102 consists of two main tanks for alkaline and acid solution and one vessel used for neutralization of solutions.

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 100l

- Voltage: 380-400V

Our tunnel container washers are designed to wash different kinds of plastic containers.

- Material: Stainless steel

- Heating power, kW: 15/ 20

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The washer-elevator-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

The destoner lift machine is designed for pre-washing and transporting root vegetables such as potatoes, carrots, beets, and other similar vegetables. After rinsing, the auger destoner separates floating particles like leaves and stems in the receiving hopper, while the product is conveyed up to the discharge height using a screw lift.

- Allows you to separate stones, leaves from root vegetables

- Pre-washing of root vegetable crops

- Two functions in one unit: washing and transporting

- Spacious hopper/tub for loading the product

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V