WBS bubble washers belong to continuous washing equipment and are used for cleaning fruits and berries before processing.

Bubble washers are designed for efficient and gentle washing of a wide range of fruits and berries with a delicate structure by sparging the working fluid (passing gas under pressure through the working fluid).┬Ā

The washers of this type are equipped with the integrated transporting conveyor for transporting the product from the washer to the next processing phase. They have a function of gradual exchange of water during washing: inflow of fresh water at the exit of fruits from washer, outflow of waste water at overflow at the entrance of fruits in the washer.┬Ā

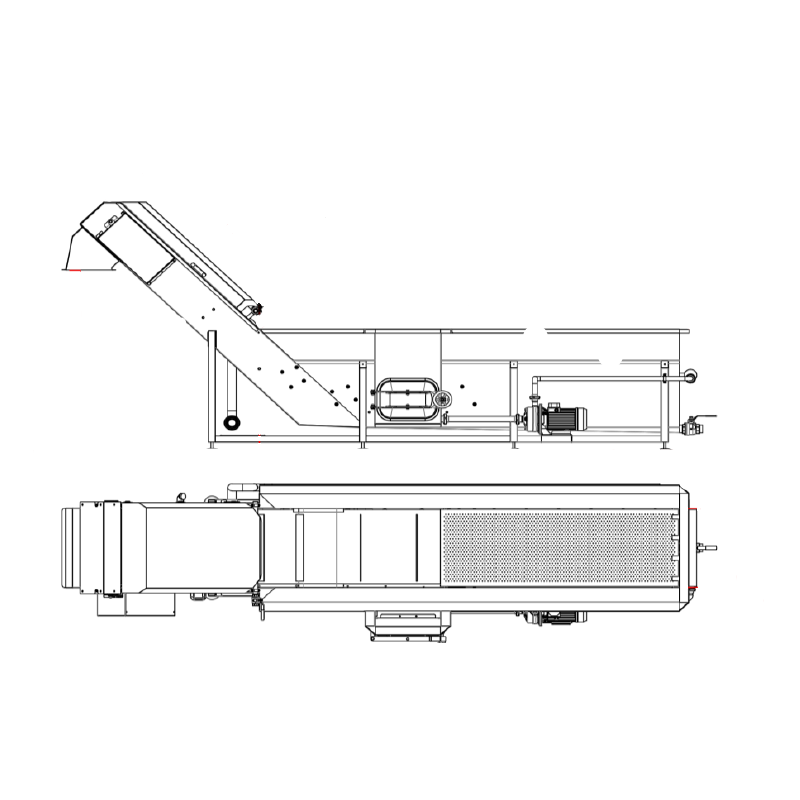

Principle of operation:

The raw material is loaded into a bath filled with water, where, using a turbulent flow of water, it mixes and washes. It is pushed out by air bubbles and immersed in water again. Thanks to the used system the surface of the fruits and berries cleans gently without any damage. Due to the internal system of water circulation, the washing intensity increases and the raw material moves along the washing batch to the conveyor, which is equipped with an additional rinse system.┬Ā

When the product gets on the integrated transporting conveyor, it moves upward, where an additional rinse system sprays the product with water again. Thereafter the raw material unloads automatically and goes to the next processing phase.┬Ā

Products:

- cherries

- grapes

- peaches

- apricots

- pears

- apples

- nectarines

- kiwi

- lychee

- nuts

- sunflower seeds

- pumpkin seeds

- and many others

Benefits:

- Hygienic Design

- Gradual exchange of water during washing

- Low water and energy consumption

- Easy cleaning of the whole washer after use

- Speed regulation with frequency converter

- Simple and continuous operation

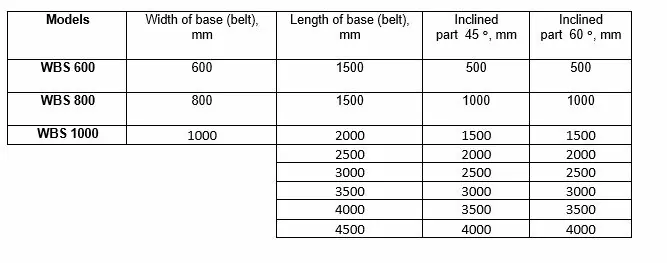

The bubble washers are available in several modifications:

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

We offer a wide range of washing equipment tailored to diverse food products, ensuring optimal cleanliness and preparing your fruits and vegetables for the next processing stage.

- Productivity: 2000 kg/h 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

Wheat washer, huller and separator is used for the preparation of grain for milling. Price depends on your production capacity.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

CIP-202: Cleaning-In-Place - Machine for cleaning and disinfecting vessels and pipelines in breweries and other food processing plants with two 200 liter tanks.

- Material: Stainless steel

- Country of origin: EU

- Volume: 200l

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

Fruit washer is designed for washing and cleaning products such as fruit or vegetables before processing, especially apples.

If you're looking for any other fruit and vegetable washers, send us a request.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

CIP-302: Cleaning-In-Place - Machine for cleaning and disinfection of vessels and pipelines in breweries and other food processing plants with two tanks of 300 liters.

- Material: Stainless steel

- Country of origin: EU

This open tank is intended for washing the juice tanks. Kapacity 250L.┬ĀFor more information, send us a request.┬Ā

- Material: Stainless steel

- Volume: 250l/

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

CIP station CIP-101 With a usable capacity of 1├Ś100 liters, it is used for cleaning, sanitizing and sterilizing vessels and pipes in a brewery. This type of CIP station is recommended for cleaning and sanitizing tanks from 0 to 4000 liters.

- Material: Stainless steel

- Country of origin: EU

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

CIP-201 - installation for cleaning and disinfection of vessels and pipelines in breweries and other food industries with one tank of 200 liters.

- Material: Stainless steel

- Engine power, kW: 0,75

- Voltage: 380-400V