Condensation drying cabinet MAK DRYER 7-14

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

A professional dehydrator for vegetables and fruits is used for drying food on an industrial scale; it is an effective, fast and most cost-effective solution in terms of energy costs for a single drying cycle.┬Ā

The cabinet dryer is suitable for the dehydration of a large number of products:

|

|

|

|

|

|

|

|

|

|

Using this dryer you can obtain high-quality fruit chips with a natural color, such as apple chips, without prior preparation and pre-processing. It is also possible to produce various types of dried meat - jerky.

Advantages:

- The main advantage of a condensate dryer is its energy efficiency - for every 1 kW of energy consumed, it can effectively utilize up to 4 kW of heat energy.

- Dehydration at low temperatures, the product does not change its natural color and taste.

- Preservation of vitamins, nutrients and natural sugars in the products without being caramelized.

- Thermal insulation of the cabinet body: minimal heat loss (optional).

- The ability to check and control the volume of condensate - water that evaporates from the product and is expelled from the system during the drying process.

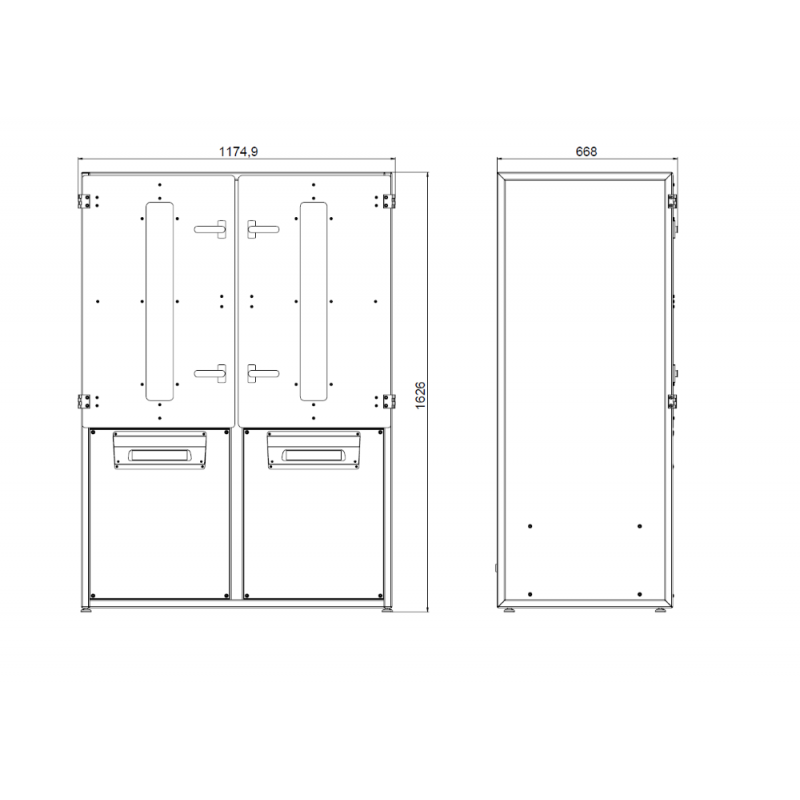

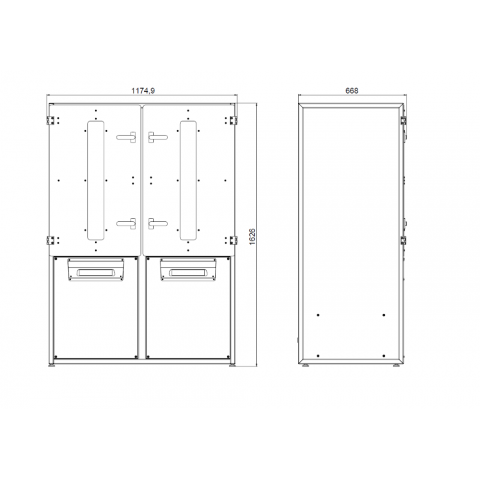

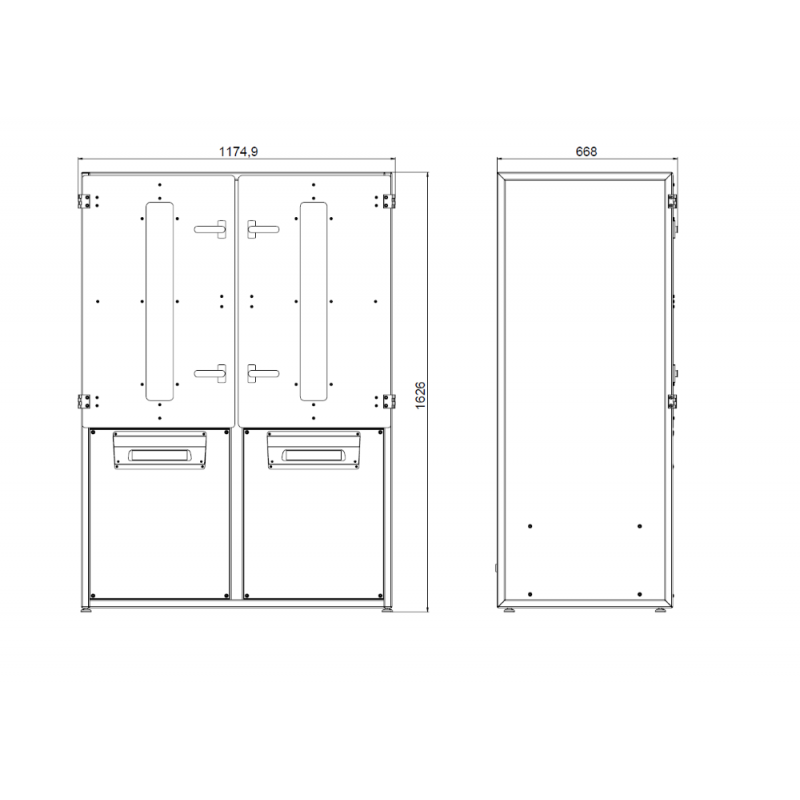

- Large drying area, this model is designed with the option to double the drying space (optional). Size of one shelf: 512x612 mm.

- Convenient and simple control and maintenance, connection to a 220-240 Volt network.

The basic version┬Āof the installation includes a two-section cabinet with 22 shelves/trays. Stainless steel doors are equipped with sectional organic glass inserts for visual control of the drying process. The system is equipped with 2 units utilizing Heat Pump technology, where the operational principle involves passing moist air through a special heat pump, rather than expelling it from the device. The moisture condenses and is removed as condensate using a hose at the lowest hydraulic point of the installation. Heat is virtually not lost; due to the directed forced movement of air, it moves in a circle, effectively drying the product on each side. The doors are equipped with a special seal that fits tightly to the cabinet frame; double locks on each section fix its position, which significantly minimizes heat loss. The installation is made out of food grade stainless steel, including the shelves.

Options:

- Double stainless steel body with thermal insulation

- Additional set of shelves (+20 pcs)

- Digital probe with a display for measuring temperature and humidity

- Hanging hooks for drying meat and fish

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

You might also like

Condensation dryer for vegetables, fruits, berries, mushrooms, herbs and other products. The condensation drying method is the most energy efficient way to dry food. The installation is intended for use in the food industry.

- entirely made out of food grade stainless steel AISI304

- polished external coating

- fully automatic control system

- 100% insulation without freon (70 mm)

- Volume: 250l/ 550l/ 1225l

- Voltage: 220-230V

- Number of shelves: 6/ 11/ 22

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

Fast, sleek, quiet, user-friendly, safe, smooth-running commercial salad dryer, designed to efficiently dry up to 6 Kg.

- Engine power, kW: 0,55

- Principle of operation: Batch mode

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

Industrial vacuum dryers are designed to remove moisture from sensitive or heat-sensitive food, chemical, or pharmaceutical products under reduced pressure, allowing for lower drying temperatures, minimized thermal degradation, and improved energy efficiency. Vacuum dryers like these are used in various industries - food, chemical, pharmaceutical and others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The simple dryer provides a reliable and cost-effective solution for food producers looking for precise control over the drying process.

- Material: Stainless steel

- Principle of operation: Batch mode

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

Working volume: 1000 l =┬ĀHoney dose: 1500 kg

Working volume: 2000 l =┬ĀHoney dose: 3000 kg

The price depends on the chosen option.┬Ā

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450

The cylindrical drum rotary machine is designed for drying and crystallizing liquid and paste food products into solid crystals.

- Compact tabletop design

- Automatic knives for cutting the product film

- Adjustable product layer thickness when applied to the drum

- Adjustable drum rotation speed to control drying time

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000