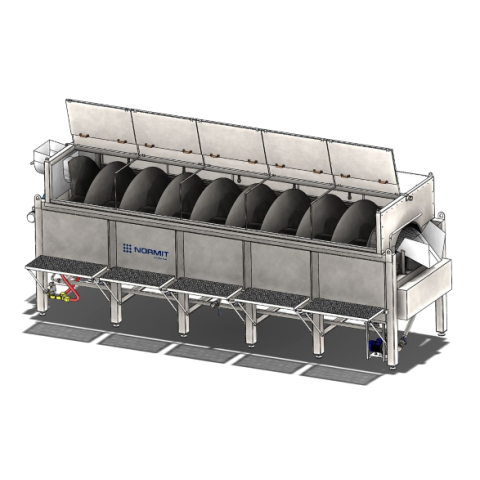

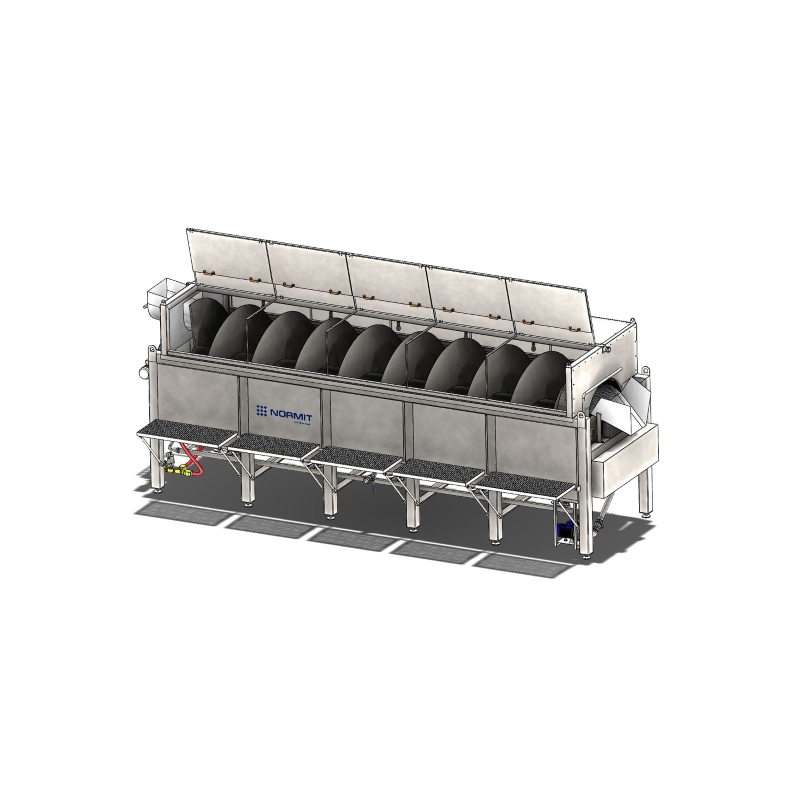

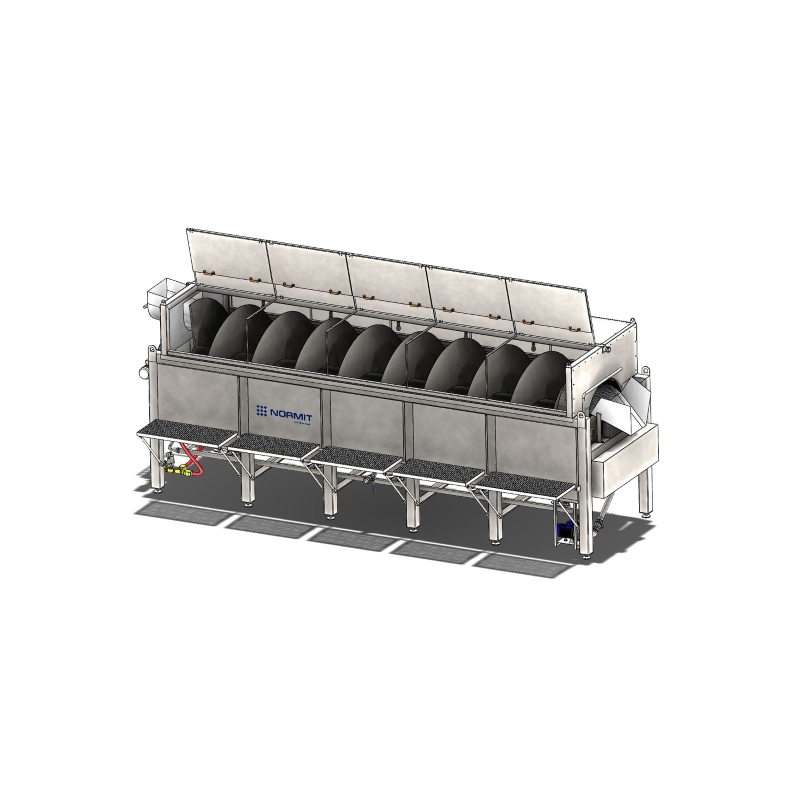

Continuous screw cooker COOK C PROFI

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

Continuous cooking saves time. From an economic point of view, the machineŌĆśs biggest advantage is that it operates in a continuous mode, which means that you are not wasting time filling the basket, which also needs to be lifted, put into the cooker, and after cooking lifted again, emptying it etc.

Another advantage is that it doesn't use the heat exchanger for heating, there is instead a direct injection of steam into the product. It is the most effective way of heating liquids with steam.┬Ā Cleaning the product Another crucial advantage of the machine is that it is designed to also clean the vegetables which float, its dirt falls down and its fed to the tanks. When the tank is full, the valve opens, and releases the dirt. |

.png) |

||

|

Technical data:

Technical features:

|

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Cooker Cook C Profi

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.┬Ā

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

Heating: integrated electric. Price depends on the production capacity and product.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l/ 200l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

.png)