This batch catering cooking equipment is made in four types of supply: oil, gas, electricity, and steam.

The catering cookers are designed to operate in automatic mode by using the controller to control the technological process.

BENEFITS OF A PROFESSIONAL HEAT BOILER / COOKER:

Heat Boilers are fed with oil, gas, or electricity and have a double heat jacket. In the case of a heating boiler with an electric supply, the heaters are filled with heating oil shell heat transfer s2. The use of a double heat jacket has two advantages:

- The first advantage is that the product doesnŌĆÖt burn.

- The second advantage is that the oil is cooling down more slowly so that in everyday work it starts from a higher temperature than the ambient temperature, thanks to which it heats up more quickly.

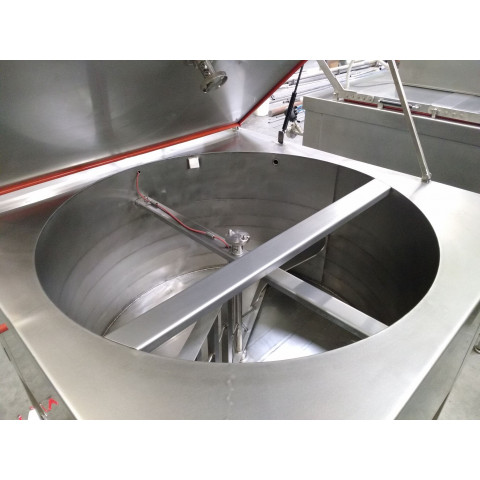

When melting lard in heat boilers, a rotary arm is used to mix the product during the process. External dimensions can be changed according to the customerŌĆÖs needs. Double heated jacket filled with heating oil Shell Heat Transfer Oil S2. 3 x temperature measurement: oil, water, batch construction, a basket made entirely of stainless steel.

COMMERCIAL COOKER 300L

- supply medium: electricity, steam, oil, gas

- installed power (kW): 15

- power supply (V/Hz): 3x400/50

- external dimensions [LxWxH mm] 600x1300x1100

- controller: mikster INDU 50

- water connection: 1/2 inch

- External dimensions can be changed for the customer's needs

CATERING COOKING EQUIPMENT 400L

- supply medium: electricity

- installed power (kW): 25

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1300x1250x1050

- controller: mikster INDU 50

- water connection: 1/2 inch

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

BATCH COOKING MACHINE 500L

- supply medium: electricity

- installed power (kW): 30 kW

- power supply (V/Hz): 3x400/50

- dimensions [mm] 1450x1250x1050

- controller: Mikster INDU 50 (among others function of the timer, that allows to set time of beginning of cooking)

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- 3 x temperature measurement: oil, water, batch

- construction, a basket made entirely of stainless steel

PROFESSIONAL KITCHEN EQUIPMENT 600L

- external dimensions ŌĆō 1600x1250x1050mm

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 200 L

- water connection: 3/4''

- water drain: 2''

PROFESSIONAL TILTING COOKER 800L┬Ā

- external dimensions - 1900x1250x1050mm

- heating medium ŌĆō electricity

- heating power- 50 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- water connection: 3/4''

- heat jacket capacity: 250 L

HEAT BOILER WITH TILTING BASKET 1000L┬Ā

- external dimensions - 2100x1250x1050 mm

- heating power- 60 kW

- microcontroller: Mikster INDU 50

- measurement of three temperatures (oil, water, batch)

- max temperature of oil: 140 C

- water connection: 3/4''

- Double heat jacket filled with heating oil Shell Heat Transfer Oil S2

- heat jacket capacity: 300 L

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

You might also like

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.┬Ā

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

The Batch Blancher Cook & Chill is designed for boiling, frying, heating and cooling of a wide range of products.

Price depends on the chosen option.┬Ā

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

The blancher is primarily intended for blanching lumpy products such as mushrooms and vegetables.

Price depends on the chosen options.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 450

- Geometric volume: 550 l

- Dimensions, mm: 1770x899x997

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

The gas cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. This cooking equipment is not suitable for roasting or baking.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 80l/ 100l/ 150l/ 200l/ 300l

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110┬░ ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Material: Stainless steel

- Heating power, kW: 18/ 27

- Voltage: 380-400V

The atmospheric batch cooker model UniCook E or UniCook S, featuring a stirrer, is tailored to meet the diverse cooking needs of various food production businesses in industrial settings.

- Heating: Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 1000l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

This gas powered professional cooker is indispensable in professional kitchens. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Heating: Gas

- Material: Stainless steel

- Working volume: 100l/ 150 l

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.┬Ā

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Atmospheric cookers ASC are designed for efficient mixing, heating and cooking products for food and cosmetic industries. Volume, l: 100 l.

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 100l

Complete set of equipment for processing shelled beans, and the production of a soy base with a capacity of 800-1000 liters per hour.

- Productivity: 800 l/h

- Material: Stainless steel

- Country of origin: Slovakia

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Unbeatable price for highest quality material, modern technology, cylinder design. We offer different capacity catering cookers, electric, steam or gas.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l/ 200l