Electric cream cooker MK-series

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

The universal kettle of the MK series is a modern food processing device with a wide range of applications in confectionery, bakeries and other catering establishments.

High-quality materials used in the manufacture of the machine ensure a long service life and trouble-free operation. The entire structure is made of AISI 304 food grade steel, resistant to corrosion and most acids, sterilization solutions, most organic chemicals and dyes. The unit evenly heats the entire contents of the working tank up to a maximum temperature of 150°C. Simultaneous heating and mixing is possible.

Thanks to its well-thought-out design, the universal cooker can be used for many technological processes, such as:

- preparation of puddings, jelly, kaymak, milk, sauces, soups, vegetables, etc.

- preparation of choux pastry and custards,

- preparation of tiramisu, fillings, jams and preserves, risotto, fruit mousses

- melting chocolate and fudge, icing,

- frying vegetables, fruits, onions

- and many more.

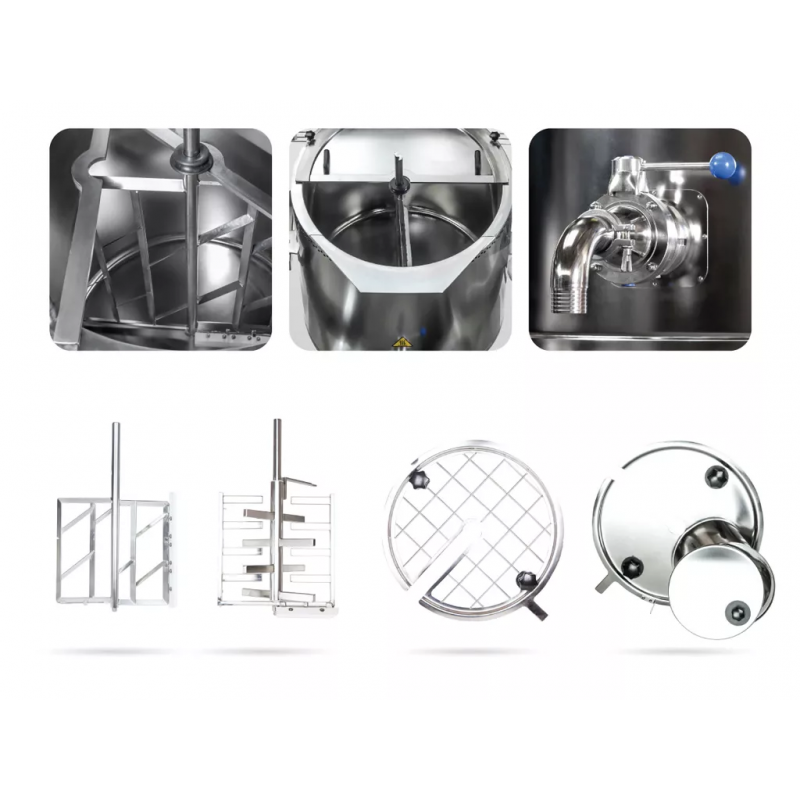

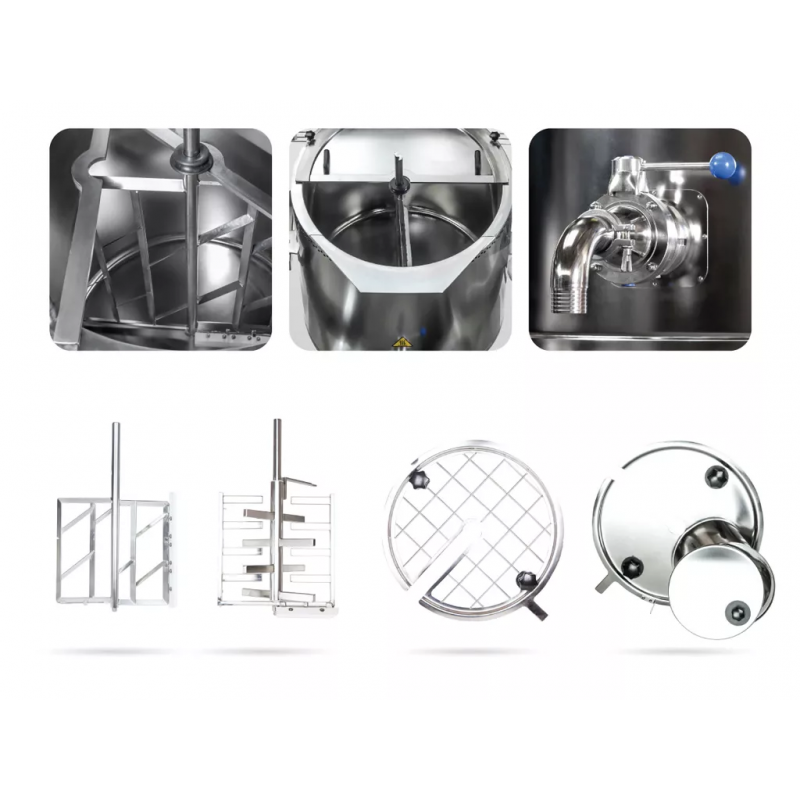

The mixing process is carried out using a special mixer, which is equipped with scrapers that prevent sticking and burning of the product. Scrapers collect the product from the walls and bottom of the pressure cooker. The heating of the product is carried out by heating the oil between the two walls of the kettle, which ensures the uniformity of heating, and the product does not burn. The product is heated evenly throughout the volume.

The universal kettle of the MK series is additionally equipped with a third outer shell to limit the return of temperature to the environment. Machines of the MK series have two operating speeds and the ability to heat the mass to the required temperature max. 150°C. At the request of the customer, it is possible to block the maximum temperature level. If necessary, the value of the maximum temperature can be increased. All elements in direct contact with the food product are made of high quality acid-resistant steel and materials approved for contact with food products.

The Cream Cooker has a tilting tank that allows easy unloading of the product and cleaning of the working container, the kettle can also be equipped with a drain valve - it can be easily disassembled for cleaning / rinsing. The valve has a protection function against accidental opening. The choux pastry and cream machine has a lid with an inlet to control the process and add ingredients without stopping the machine. All important electrical components are located in the electrical box on the side of the machine to protect against fumes and high temperatures. Timer with sound signal - automatic or manual mode.

Machines of the MK series are designed for the production and preparation of choux pastry, creams, chocolate, fudge, jams, glazes, fillings and various mixtures according to original recipes, as well as for any product that requires uniform heating and smooth mixing. Often used in confectioneries and bakeries. It can also be used in the cosmetic industry, for the preparation of sugaring paste.

The mixing process is carried out by mixing tools with side and bottom scrapers, which prevent sticking and burning of the mixture. Scrapers are designed to collect layers of mixture from the walls and bottom of the bowl.

- Quick scraper removal system with no tools to clean or replace

- Thermal oil poured between two layers of âjacketâ provides even heat distribution, safe during operation.

- The outer, third layer of the bowl prevents heat loss from the machine.

- 2 working speeds (variable on request)

- Maximum temperature up to 150°C, on request max. temperature can be set to another, lower level.

- All parts in contact with food are made of high quality acid-resistant steel or food-grade materials.

- Tilt bowl with stop in any position for easy emptying and cleaning - motorized wheel for models MK-200/300/500

- Bowl lid with viewing window to monitor the process and add ingredients without having to stop the machine.

- All important electrical components are inside the electrical box on the side to prevent smoke and high temperatures.

- Timer - manual or automatic operation

- Protective thermal switch

- Ball valve Du-80 â standard for MK-200/300 and 500 series.

- Each machine can be equipped with a crane (on request)

- Mobile, on wheels

Additionally:

- Variable speed (inverter)

- Cooling system with cooler â available for all models

- Bowl Lid/Grid â available for all models

- Special double agitator â available for all models

- LCD â 7â² â fully programmable control panel with recipes

- Laser product temperature sensor.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

You might also like

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Equipment for the production of creamed honey, soufflé honey, whipped creamy honey. The machine is produced both in atmospheric and vacuum versions, the loading capacity ranges from 70 to 3500 kg of honey.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.Â

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

- Material: Stainless steel

- Principle of operation: Batch mode

- Working volume: 50

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications.

- Heating: Steam

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350 l

The Economy series of the cooking kettles comprise a thick-walled stainless steel container with an electric mixer mounted on the quick-release upper housing. The installation allows you to mix and stir products during processing. The thick bottom of the pot allows it to be installed on all types of heating surfaces (gas, induction or electric stove).

The Economy version is recommended for use with low-viscosity liquid products; If processing more thick and viscous products is necessary, we offer the Premium version of the cooking kettle or the caramel & syrup cooking kettle for extra thick substances.

- Sandwich bottom (multilayer) for use on all types of hobs, including induction

- Quick release lid with an electric stirrer

- Safety grid under the upper hull hatch - safe handling when stirring

- Possibility of visual inspection through the safety grid during processing

- Safe loading of components even during mixing

- Material: Stainless steel

- Engine power, kW: 0,12

- Volume: 30l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia