Tilting Bratt Pan

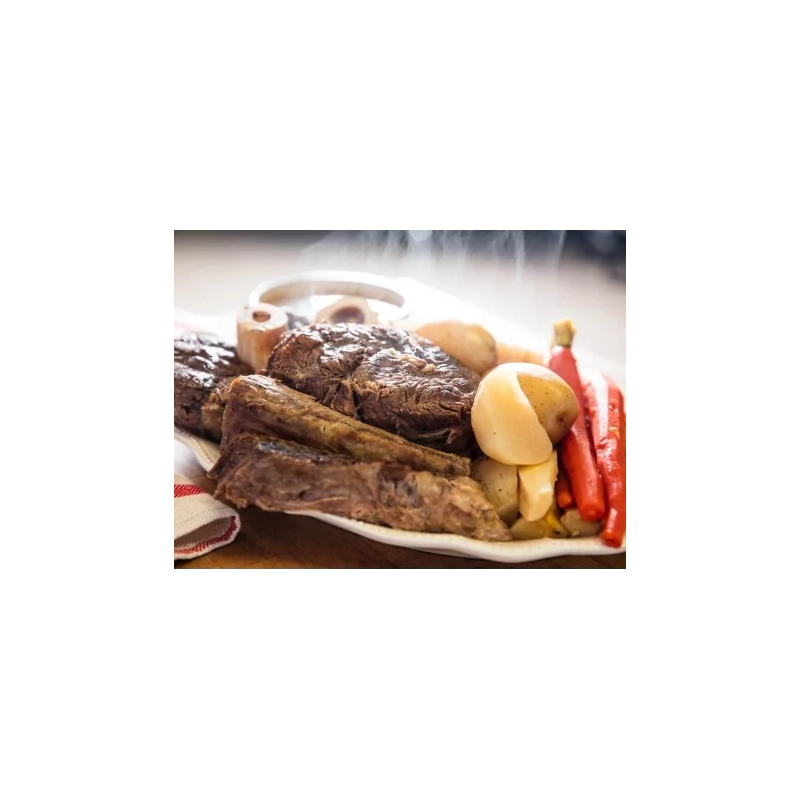

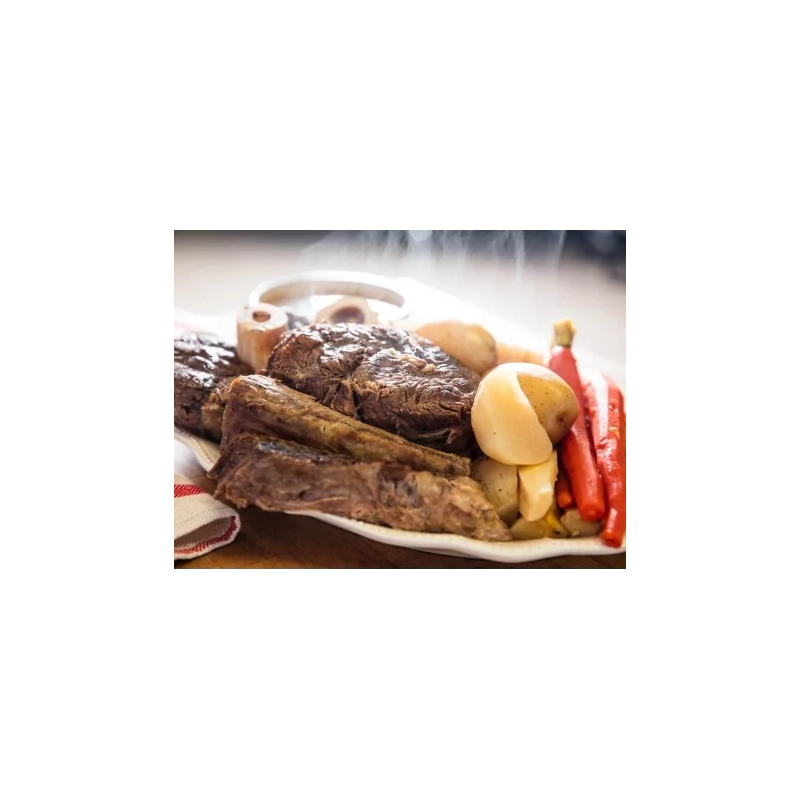

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

The tilting bratt pan is intended for professional use in the food industry for hospitals, catering facilities and large kitchens.

This cooker is suitable for cooking soups, making pasta, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, soups, etc.

It can be produced in gas or electric heating versions. High-quality technologies and materials are used in the production of the tilting bratt pan whereby it fulfills the high utility and sanitary requirements. Thanks to the functional elements that our cooking unit possess, they can be used as different devices such as a frying pan for slightly fried food or as a heat/ steam boiling pan for wet cooking- the ideal variant for sauces, stews preparation.

Processes:

- Braising

- Frying

- Blanching

- Sautéing

- Boiling

- Heating

- Steaming

Products:

- Meat products

- Vegetables

- Goulash

- Meat stew

- Sauces

- Dressings and many other products

Technical features:

- easily handling

- ergonomic design

- high performance for gas version: from 10,3 to 23 kW

- high performance for electric version: from 14,5 to 32 kW

- recessible ratchet

- cover can open with the lever from the side, in this way the condensing steam can be avoided

- manual water filling

- can be installed under the recirculating hoods

- surfaces from stainless panels

- high-quality components from Europe

- carbon steel bottom

- voltage: ~ 3N x 400 V, 50 Hz

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

You might also like

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

This 160L or 220L professional cooking pot is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams.

- Material: Stainless steel

- Heating power, kW: 18/ 27

- Voltage: 380-400V

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This 60 liter cooking kettle is indispensable for cooking large amounts of food. Runs on gas and handles all basic cooking tasks with ease.

- Material: Stainless steel

- Principle of operation: Batch mode

- Working volume: 50

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110¬į ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Chocolate heating pump is the perfect solution to upgrade your production line. You can easily connect the pump to any device (such as a chocolate enrobing machine).

- Principle of operation: Batch mode

- Voltage: 380-400V

MP cooker is a reliable and extremely functional solution for cooking, pasteurizing in the same tank thus saving equipment cost, space. All material are most reliable in European market so guarantee a long and trouble free operation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

We sell many different types of cooking equipment, with a mixer or without, tilting cookers, with capacities from 100 - 350 liters.

- Material: Stainless steel

- Country of origin: EU

The vacuum cooking and concentration unit is designed for concentrating products at low temperatures (about 60 degrees) in a reactor with a discharged environment to preserve the color, nutritional value and useful natural substances in present in food products. Evaporation and concentration units are often used when cooking jams, sauces, as well as fruit or vegetable concentrates. The vacuum concentrator allows you to boil and concentrate heat-sensitive products without damaging or destroying their structure or proteins, such as milk.

- Inclined design - allows for gravity mixing, which is 40% more efficient than usual

- Quick and 100% emptying of the tank thanks to the inclined design with the mixer on

- Heating/cooling jacket (duplicator) for the working tank and bottom

- High hygiene standard - the output valve is located at the lowest hydraulic point of the reactor

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 500l/ 875l

Round cooking boiling pan combines together the advantages of cooking with automatic mixing. Designed for catering industry, school kitchens, restaurant kitchens or food industry. Capacity ranges from 100l to 500l. The available heating options are - steam boiling or indirect electric heating.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

Automatic cooker made for continuous batch production. Different types of food can be boiled, like pasta, rice, vegetables, meat etc. Options: direct gas, indirect steam boiling or direct electric.

Price depends on chosen option.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Heating power, kW: 2x25

- Volume: 2x135l/ 2x220l

- Steam consumption, kg/h: 2x70/ 2x100

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ¬įC and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V