Vacuum honey dehydrator / dryer PD3000

Working volume: 1000 l = Honey dose: 1500 kg

Working volume: 2000 l = Honey dose: 3000 kg

The price depends on the chosen option.

Honey dehydrator vacuum NORMIT

Vacuum honey dehydrators series PD are designed for intensive and gentle removal of excess moisture from the honey under vacuum conditions.

Excessive moisture content in honey (over 18-20%), due to its early collection or poor quality, leads to difficulties in long-term storage, as well as separation and fermentation.

Increase in productivity

In vivo bees spend a considerable amount of time and effort on the final drying of honey in the hive. The possibility of conducting a final drying of honey after its extraction from the frames significantly increases the honey harvest per season. Removal of moisture without increasing hydroxymethyl furfural content. Honey dehydrator has been designed specifically for honey, bearing in mind all the features of this sensitive product, and can effectively remove moisture without heating, or with low temperature heating that does not lead to increased content of hydroxymethyl furfural. Honey dried in the Normit series PD and VD vacuum dryers can be used in the pharmaceutical industry.

Efficiency of the honey dehumidifier

Efficient removal of moisture from honey is performed not only by the vacuum, but also by means of the largest possible heat exchange and heat transfer area which includes the inner walls of the working chamber and the entire surface of the disk agitator. Due to the large heat exchange surface, we have significantly lowered energy costs for the evaporation of moisture, when compared to conventional vacuum drying apparatuses.

Additional features

Besides the drying of honey, this model can be used for the manufacture of invert sugar, for the production of artificial honey. This means you can use the equipment all year round, even when the natural honey-processing season is over. Artificial honey is a nutritious and very popular product in the confectionery industry, also often used for the feeding of bees during the winter period.

Design

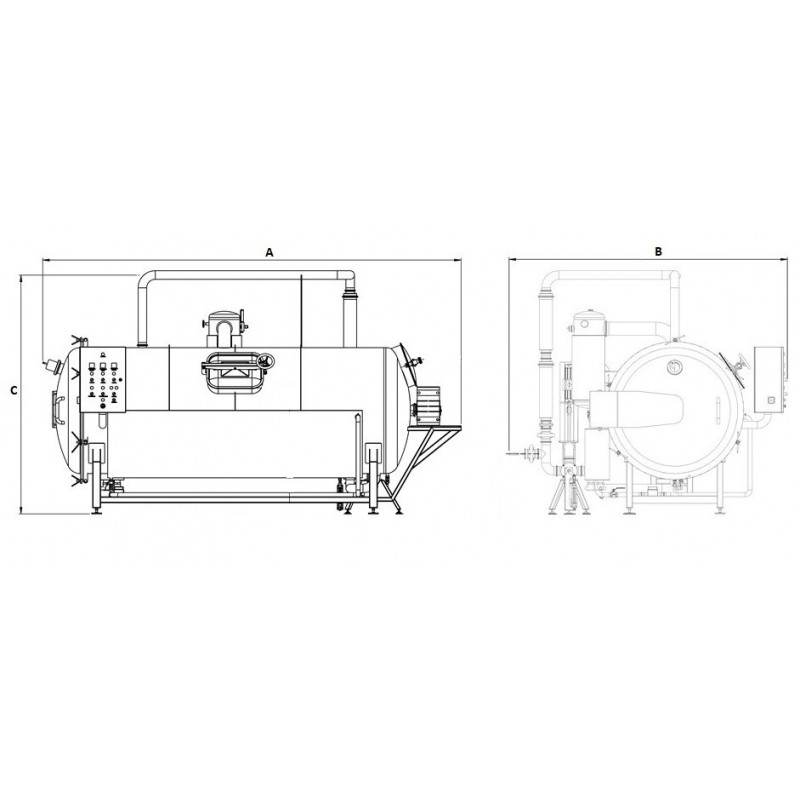

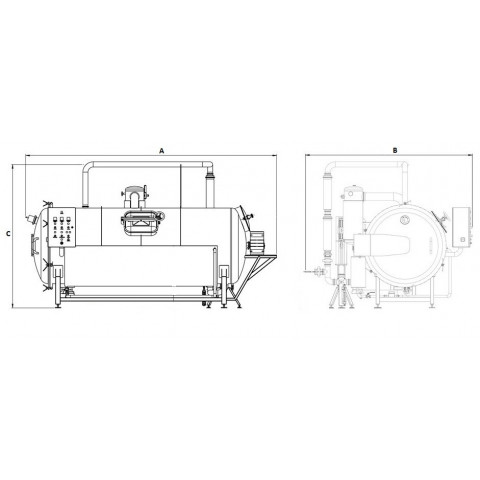

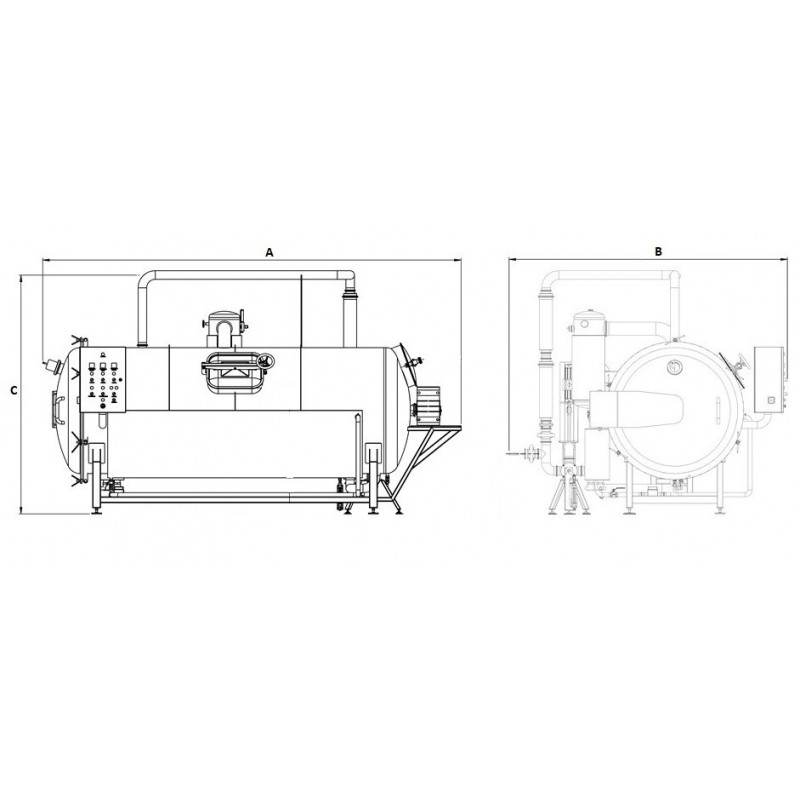

Vacuum honey dehumidifier series PD consist of a vacuum chamber made of stainless steel AISI304 (or AISI316 on request), equipped with a specially shaped disk stirrer system with scrapers, vacuum system, condensate and a control system based on industrial controllers. Condensate removal is carried out by a high-performance innovative cyclone separator.

Vacuum honey dehydrator series PD are equipped with a built-in refractometer for controlling the level of moisture content during the process of evaporation. The dryer can be equipped with an optional recirculation loop and honey filtration system. Filters in the filter system are interchangeable and made of stainless steel, and allow for both basic cleaning from large impurities and ultrafiltration to remove pollen grains.

Advantages of honey dehydrator

- Sanitary design in accordance with FDA and GMP requirements.

- EU-made with high quality materials and components.

- Gentle moisture removal without heating or with minimal heating, preserving all the beneficial qualities of honey.

- Can be used for the production of pharmaceutical honey.

- High efficiency evaporation at low energy cost and for a short period of time.

- Low noise, and lack of harmful emissions.

- It allows for a significant increase in the amount of honey harvested per season, with the ability to achieve high quality and gentle final drying of honey straight from the hive.

- It significantly improves the quality of the unripe honey and increases its shelf life. Processed honey is not separated and does not ferment.

- During the drying process, honey may also be filtered.

- The honey dryers Normit series PD and VD have a robust design, which is easy to operate and maintain, clean, and designed for operation on a twenty-four hour basis ‚Äď whenever you need it.

- It can be loaded with liquid or partly melted honey.

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450

You might also like

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

- Productivity: do 12000 kg

- Material: Stainless steel

- Volume: 8000 l

Working volume: 1000 l = Honey dose: 1500 kg

Working volume: 2000 l = Honey dose: 3000 kg

The price depends on the chosen option.

- Productivity: do 3000 kg

- Material: Stainless steel

- Country of origin: Slovakia

- Working volume: 2000 l

- Geometric volume: 4000 l

- Dimensions, mm: 4300x2760x2450

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

Deaerator is used for the removal of air bubbles from the puree. Price depends on the required volume and production capacity.

For more information, send us a request.

- Productivity: 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

The unique feature of this vacuum honey evaporator model, distinguishing it from a honey dryer, is its ability to create a deep vacuum with a residual pressure of up to 0.08 Bar during processing, and thus lowering the processing temperature! This innovative unit not only allows for quick and efficient drying of honey but also enables the immediate evaporation of water, producing a semi-finished product suitable for the subsequent production of ¬ędry honey¬Ľ or powdered honey.

- There is no need to have a large drying surface ‚Äď an evaporation mirror.

- There is no need to install a mixing device for thick and viscous products.

- Low evaporation temperature of moisture ‚Äď water from honey, at which its quality and medicinal properties are not compromised, and the risk of HMF growth is reduced to almost zero.

- Fast and efficient dehydration of honey at a low processing temperature.

- Material: Stainless steel

- Principle of operation: Batch mode

- Max vacuum: -1 Bar

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39¬įC without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

This multi layer belt dryer with integrated cooling system works as a dryer and cooler in one installation.

- Material: Stainless steel

- Principle of operation: Continuous mode

Industrial vacuum dryers are designed to remove moisture from sensitive or heat-sensitive food, chemical, or pharmaceutical products under reduced pressure, allowing for lower drying temperatures, minimized thermal degradation, and improved energy efficiency. Vacuum dryers like these are used in various industries - food, chemical, pharmaceutical and others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

We offer different types of dryers for different products.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 255 kg

- Volume: 500l

- Voltage: 380-400V

- Geometric volume: 170 l

- Dimensions, mm: 2350 x1500 x2000

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m²: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

Condensation dryer for vegetables, fruits, berries, mushrooms, herbs and other products. The condensation drying method is the most energy efficient way to dry food. The installation is intended for use in the food industry.

- entirely made out of food grade stainless steel AISI304

- polished external coating

- fully automatic control system

- 100% insulation without freon (70 mm)

- Volume: 250l/ 550l/ 1225l

- Voltage: 220-230V

- Number of shelves: 6/ 11/ 22

The high quality atmospheric condensate honey dryer is designed specifically for professional honey dehumidification.

The price depends on the options you choose.

- Material: Stainless steel

- Working volume: 2000 l

- Dimensions, mm: 5200x1590x1680

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode