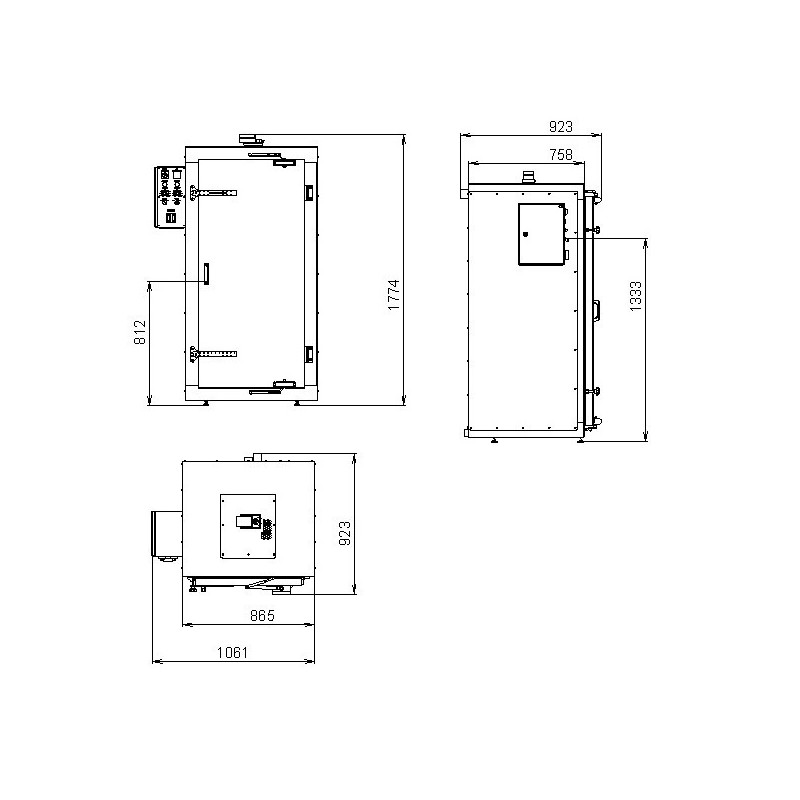

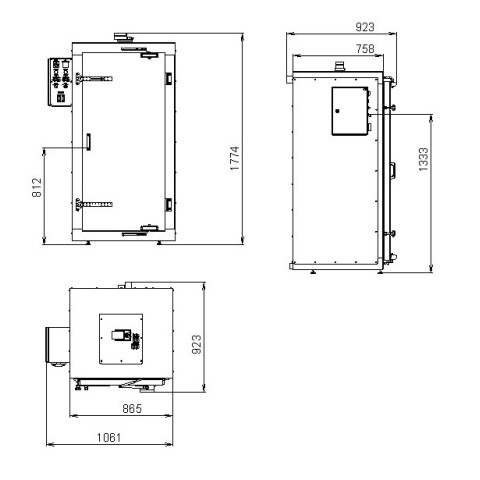

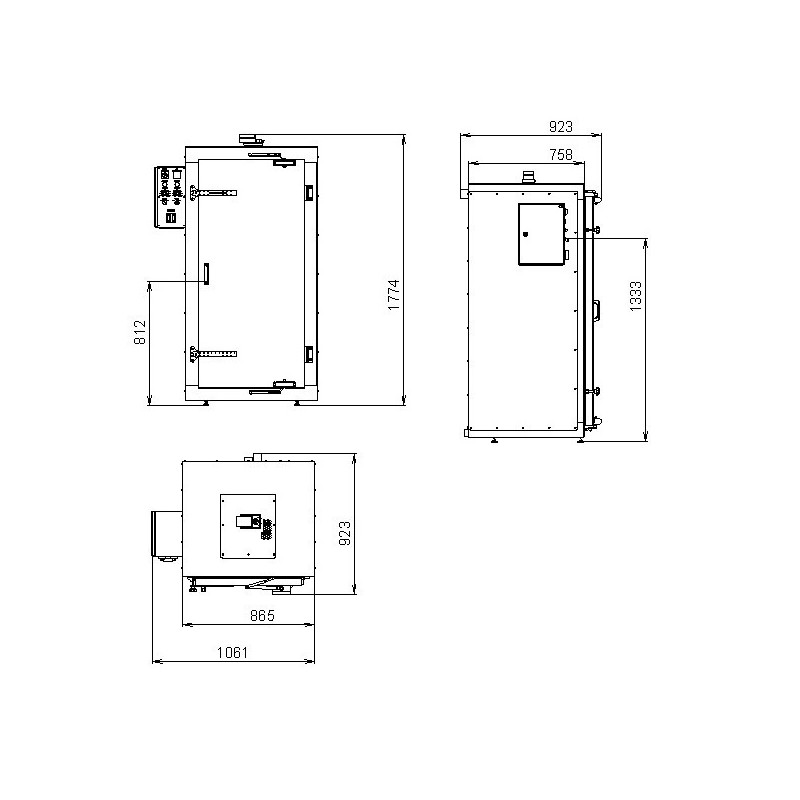

Infrared dryer for fruits and vegetables ID 3-7

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

A dehydrator is the simplest method of preservation, allowing you to extend the shelf life of raw materials without the need for special additives and stabilizers, while preserving most of the beneficial substances. With the "cold drying method," it also retains the vitamins present in fresh products. This equipment can be used to produce snacks such as frips, jerky, and much more.

A universal dryer with infrared emitters is designed for quick and efficient drying of various products:

|

|

|

|

|

|

|

|

|

|

Thanks to special deep shelves, it is possible to dry bulk products without the need to dismantle or replace trays. It can also serve as a convenient drying solution for:

|

|

|

Advantages:

- A dehydrator is the simplest method of preservation, allowing you to extend the shelf life of raw materials without the need for special additives or stabilizers. It preserves all the beneficial substances, including the vitamins found in fresh products, particularly with the "cold drying method."

- Quick drying! Approximately 20 times faster than the natural drying method, at least 3 times faster than the convective method.

- Special emitters with MWIR wavelengths that are absorbed by the product, thereby not overheating its surface, water evaporation occurs without destroying the structure at the cell level.

- Highly effective drying - high efficiency, energy is directed exclusively to the water present in the raw material; emitters do not heat the surrounding air, only the product!

- âCold dryingâ, the average drying temperature is 60 degrees, which is important for preserving nutrients and vitamins (up to 95%).

- Large drying area/drying volume.

Basic version

It comprises a two-layer stainless steel cabinet with thermal insulation, heating elements located above the shelves, a fan and a control panel.

Options:

- Different types of shelves and trays

- Non-stick grids

Recipe for beef chips - "Jerky":

- Time 2.5 hours

- Temperature 50 degrees

- Slicing thickness 3mm

- The finished product is around 30-35% the size of the original

- For meat that is 1mm thick, the drying time is approximately 1 hour

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m²: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

The price is set for the model with an area of 7 m²

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m² (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m²: 7

- Number of shelves: 22

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V

The high quality atmospheric condensate honey dryer is designed specifically for professional honey dehumidification.

The price depends on the options you choose.Â

- Material: Stainless steel

- Working volume: 2000 l

- Dimensions, mm: 5200x1590x1680

A circulation-type vacuum evaporator refers to a combined version of an evaporator that also takes advantage of other types to improve evaporation efficiency particularly by reducing concentration time and when processing heat-sensitive products such as milk.

- The external circulation circuit with heating intensifies the cyclic evaporation process.

- The forced circulation system ensures a decrease in the risk of localized product overheating.

- The condenser enables a deep vacuum and maintains a low evaporation temperature.

- Utilizing a mixing device with a spray system facilitates product evaporation in a thin layer, mimicking a film-type evaporator.

- Heating: Steam

- Material: Stainless steel

- Operation mode: Semi-automatic

- Country of origin: Slovakia

- Total power, kW: 2,4

- Voltage: 380-400V

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

This industrial hybrid drying cabinet combines two drying principles: heat pump (condensation) and convection (forced circulation of heated air). This dryer is designed for fast, efficient, energy-saving, and "cold" drying of vegetables, fruits, berries, mushrooms, legumes, herbs, meat, fish, and even liquid or semi-liquid products by replacing the shelves with standard GN 2/1 containers. The size of one shelf is 530 x 650 mm.

- Dual technology: condensation drying + hot air convection

- Energy-efficient with optimized consumption (approx. 0.9â1.3 kWh depending on mode)

- Drying area expandable up to 14 m² (optional)

- Uniform drying thanks to forced air flow and controlled moisture removal

- Gentle operation at low temperatures for maximum preservation of nutrients and color

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This convective honey dryer is used for drying and mixing honey, it is a high-performance solution for thoroughly mixing honey while simultaneously removing excess moisture.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Voltage: 230 V/ 380-400V

The price is indicated without a source of compressed air - compressor (optional).

This is periodic type of equipment designed for removing moisture and excess water from honey under vacuum conditions. This pilot vacuum dryer can be used for processing small volumes of honey directly at apiaries.

- Drying rate up to 1% per hour! (with a gradual decrease as the concentration increases)

- Large heat transfer area

- Low drying temperature thanks to the vacuum

- Easy operation and maintenance

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100 - 140 kg

- Total power, kW: 6,5

- Voltage: 220-230V 380-400V

- Max vacuum: -0,8 Bar

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

The high quality atmospheric 1500 kg condensate honey dryer is designed specifically for professional honey dehumidification.

Price depends on the chosen option.

- Material: Stainless steel

- Working volume: 1000

- Dimensions, mm: 3600x1400x2000

The vegetable spin dryer has been designed for drying leafy vegetables rapidly and efficiently, both raw and boiled, prepared in medium-large sized professional kitchens and in food industries.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Voltage: 220-230V