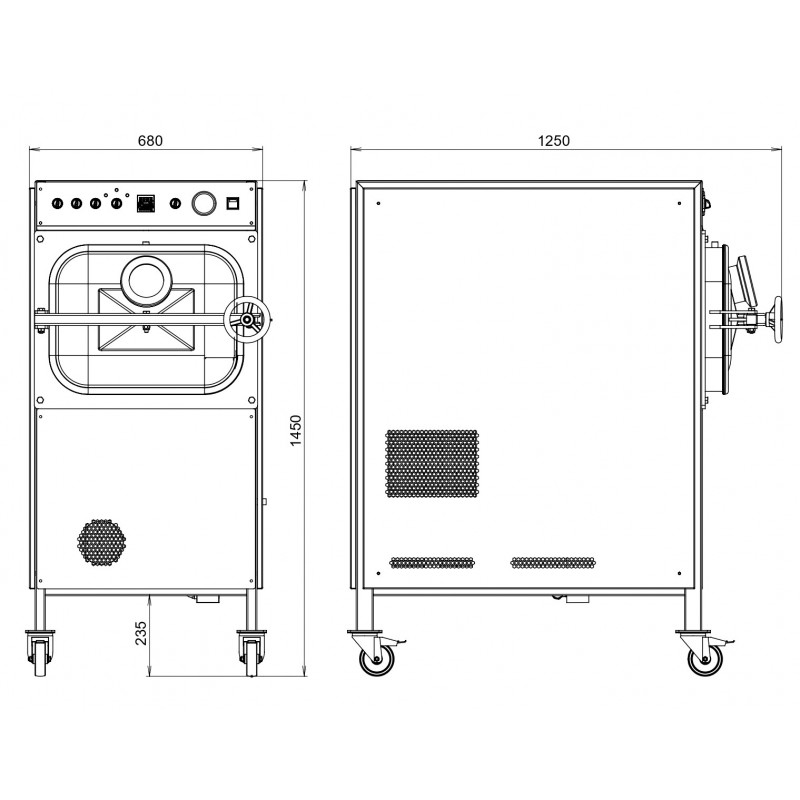

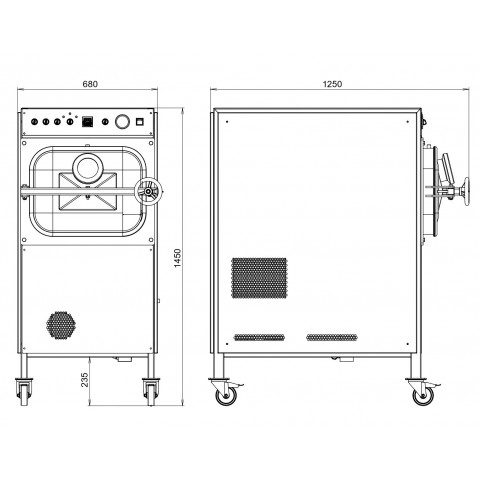

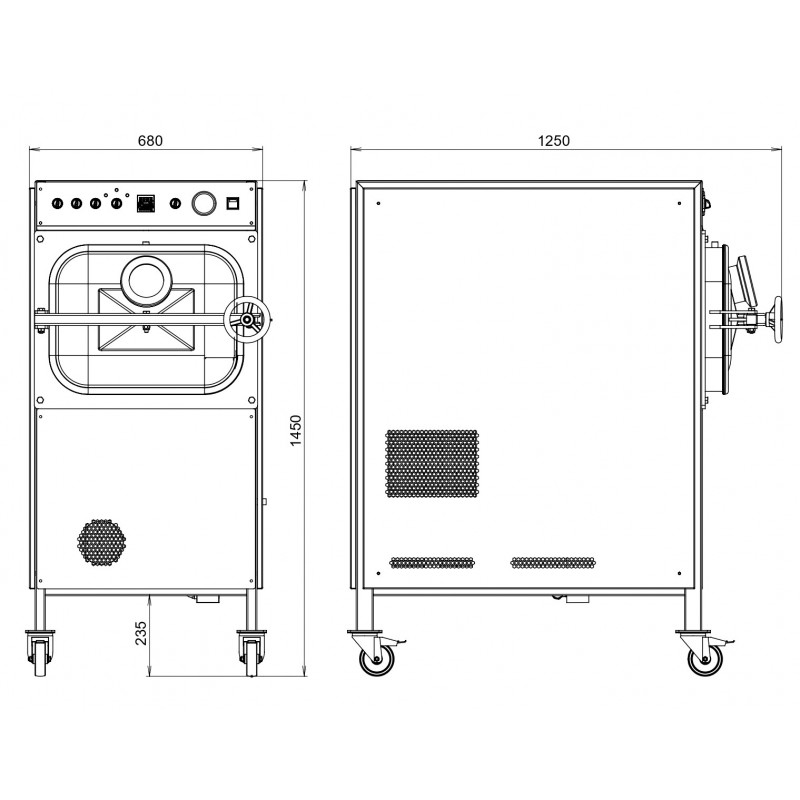

Universal vacuum drying cabinet

Designed for "cold" vacuum drying of products sensitive to high temperatures, also suitable for liquid and viscous products.

This type of drying - dehydration under high vacuum allows you to get a dry product, meanwhile not changing the product either in terms of chemical or physiological / organoleptic properties.

Keep the original taste, nutrients and vitamins. And the most important thing is the ability to remove excess moisture from products that are destroyed if the temperature rises.

The principle of operation is based on achieving a deep vacuum in a special chamber, where the deep shelves are installed, on which the product can be laid out or poured. After reaching a deep vacuum, a heat carrier is fed into the working chamber. In a vacuum depending on its depth, the boiling point of water decreases, therefore evaporation from the product occurs almost instantly when the boiling point of water in the product is reached. Steam and gas are drawn out using the vapor removal and condensation system, steam enters the condenser, where it condenses, turning into water and the gas is let out.

The unit is equipped with a built-in vacuum generation system, a cooling system with a refrigeration machine and a generator with a heating system for supplying coolant to the chamber.

The versatility of the installation allows you to place various standard volumetric gastro containers, baking sheets and shelves inside. The contact method can be used as well, the cut fruits, vegetables are clamped between two grids / trays, which increases the efficiency of moisture removal.

This equipment can be used for:

- fruits,

- vegetables,

- for drying various thick mixtures in semi-liquid and liquid form,

- for drying medicine

- various other products

Technical specifications:

- Vacuum depth, mBar - 50 (-0.95 Bar)

- Chamber volume, l - 130

- Pallet dimensions, mm - 400x600 / 530x325

You might also like

Condensation dryer for vegetables, fruits, berries, mushrooms, herbs and other products. The condensation drying method is the most energy efficient way to dry food. The installation is intended for use in the food industry.

- entirely made out of food grade stainless steel AISI304

- polished external coating

- fully automatic control system

- 100% insulation without freon (70 mm)

- Volume: 250l/ 550l/ 1225l

- Voltage: 220-230V

- Number of shelves: 6/ 11/ 22

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

We offer different capacity infrared dryers.

- Productivity: 250 kg/h/ 1000 kg/h/ 1500 kg/h/ 2000 kg/h / 3000 kg/h / 6000 kg/h

The price is set for the model with an area of 7 m┬▓

Compact condensate dryer, heat pump powered dehydrator for drying vegetables, fruits, berries, mushrooms, legumes and grains.

- Energy saving, low consumption model (consumption up to 0.9 kW/h)

- Possibility of increasing the drying area in this model up to 14 m┬▓ (optional)

- Intensive drying, each section is equipped with a heat pump

- Automatic drying system control

- Delicate drying at low temperatures

- Preservation of most nutrients and the products natural color

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 0,9

- Voltage: 220-230V

- Area, m┬▓: 7

- Number of shelves: 22

The vacuum batch dryer is suitable for gentle and high-quality dehydration to obtain a product with low solvent/moisture content.

- Special stirrer for uniform heat distribution and mixing

- Drying of heat-sensitive wet solids

- Suitable for the separation of suspensions and drying extracts

- Low processing temperature due to a deep vacuum

- Material: Stainless steel

- Volume: 300l/ 600l/

We offer different types of honey dryers with a capacity for this model ranging from 50 kg up to 1000 kg.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

We offer professional infrared dryers from 8 to 56 trays with a capacity of 200 to 3000 kg/day for vegetables, fruits, tea, herbs, mushrooms, medicinal herbs and other products. The dryers of this type is a turnkey solution based on two technologies - direct infrared and air convection drying.

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

The price is set for the basic version, without additional options.

The industrial infrared dryer is suitable for drying a wide range of products: nuts, apples, plums, strawberries, raspberries, blueberries, mushrooms, carrots, onions, garlic, herbs, meat, figs, bananas, marshmallows. If additional options are selected, it can also be used for curing and drying whole meat and fish.

- Compact installation

- Fast and efficient drying

- Possibility of selecting individual settings for drying

- Made entirely out of stainless steel

- The interior surface of the cabinet has a mirror coating

- Quiet operation of the installation

- Low energy consumption per drying cycle

- Heating: Electricity

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 7l/ 10l/ 14l

- Total power, kW: 10/ 15/ 20

- Area, m┬▓: 3,5/ 5,2/ 6,9

- Number of shelves: 10/ 15/ 20

A tilting frying pan with a stirrer and indirect electric heating using thermal oil is designed for processing small batches of raw materials, making it suitable for stewing and frying various foods. The automatic stirring feature enhances the preparation of vegetables, fish, meat, and sauces.

- Compact model

- Uniform heating due to the thermal oil

- Simple controls

- Electric tilt of the working bowl

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 140l

- Total power, kW: 19

The high quality atmospheric condensate honey dryer is designed specifically for professional honey dehumidification.

The price depends on the options you choose.┬Ā

- Material: Stainless steel

- Working volume: 2000 l

- Dimensions, mm: 5200x1590x1680

This compact nuts and seeds roaster is ideal for efficiently and evenly processing nuts and seeds to perfection.

- Productivity: 5-15 kg

- Material: Stainless steel

- Principle of operation: Batch mode

Smoking and cooking chambers are designed for thermal processing of meat, sausages, poultry, fish and cheese. You can smoke, steam, dry, bake and cool products up to 120 degrees in our chambers. Smoking chambers are made in four types of supply: oil, gas, electricity and steam.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Voltage: 230 V/ 380-400V

A vacuum honey dryer is used to dehydrate (remove moisture from) honey at sub-atmospheric pressure.

- This highly efficient and innovative vacuum drying process guarantees honey drying rates exceeding 1% per hour!

- The vacuum dryer allows for quick and gentle drying of honey at temperatures up to 39┬░C without increasing hydroxymethylfurfural (HMF) levels.

- Any heat source (hot water, steam) can be used to supply thermal energy to the dryer's jacket.

- The specially designed mixing device enhances heat transfer within the product, improving its thermal efficiency and significantly reducing drying energy costs.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Max vacuum: -0,8 Bar

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The peculiarity of this unit is the combination of several functions: homogenization and drying of honey. The vertical vacuum dryer allows you to dry honey weighing up to 3300 kg in a short time while preserving its useful properties, color, taste, and organoleptic qualities. The vacuum honey dryer has a number of significant advantages over classic atmospheric honey dryers due to the reduction of processing time and the preservation of its beneficial properties, which is achieved by drying at a lower temperature.

- The drying process occurs much faster due to the evaporation of moisture under vacuum.

- High degree of homogenization of honey due to the operation of a special mixing device.

- The narrow vertical design does not require large production areas while boasting high productivity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Industrial vacuum dryers are designed to remove moisture from sensitive or heat-sensitive food, chemical, or pharmaceutical products under reduced pressure, allowing for lower drying temperatures, minimized thermal degradation, and improved energy efficiency. Vacuum dryers like these are used in various industries - food, chemical, pharmaceutical and others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Convective rotary drum dryers are used for drying granular, loose and bulk materials. They can be used for drying salt, coffee, various granules, powders, grain, nuts, seeds, fruit/vegetable bagasse, and many other products. When used in other industries, the dryer allows for the drying of salt, sand, expanded clay granules, and other similar non-flammable substances. For more information, send us a request.

The drum dryer can be configured to operate with either electric heating or gas heating (which can offer a lot more power), depending on your specific requirements and preferences.

Warning: It is not recommended to use the gas heating option for drying substances that are highly flammable, as doing so could pose a significant fire risk.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia