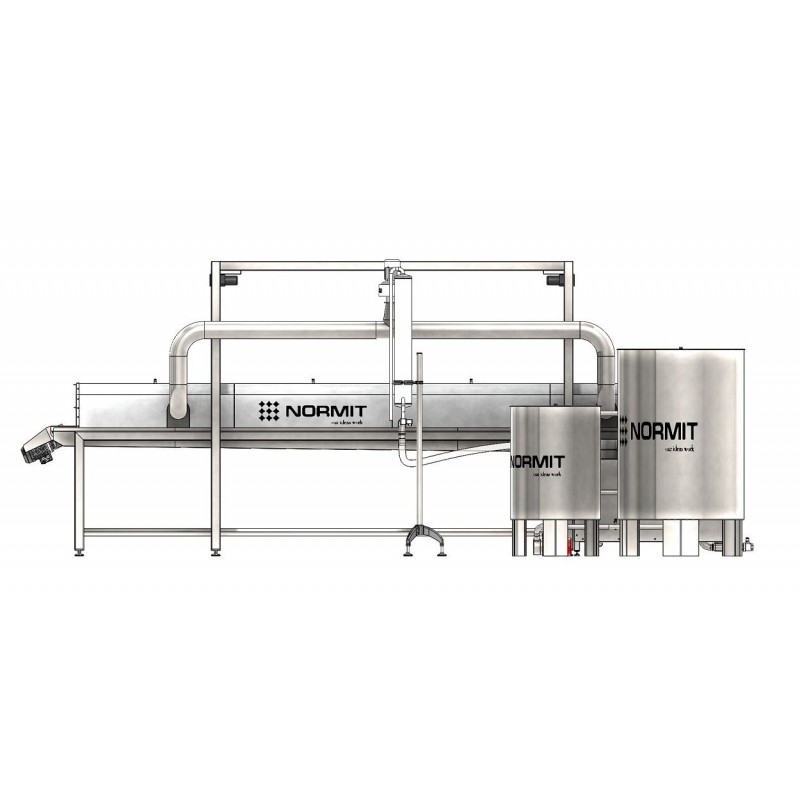

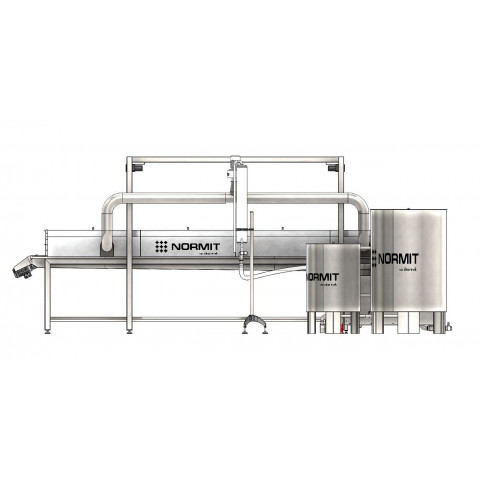

Fryer for continuously pouring hot oil ShowerFry

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method which helps to close down the pores of the product to prevent excessive oil absorption. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

Permanently pure oil due to circulation is a guarantee of a high quality finished product.

Suitable products:

- Chicken thighs

- Hamburgers

- Cut rings of eggplant, or zucchini

- Nuggets

- Croutons

Excellence in efficiency as well as environmental friendliness

The Shower Fry Continuous Conveyor Fryer series is a new sensation in the market of food processing equipment. The design of this piece of equipment, developed by our engineers on the basis of current, practical experience in manufacturing and using of conveyor fryers, ensures excellence in efficiency as well as environmental friendliness.

Universal use

ShowerFry continuous fryers use the method of pouring hot oil, which is ideal for frying meat, fish, vegetable and dough products, snacks (hard and fragile structure), both breaded and non-breaded.

Pouring with hot oil provides heat transfer performance comparable to the method of immersion in hot oil, and is effective for frying different products, including large pieces of meat and fish products, for which high-quality frying is imperative.

Minimal ratio of oil, reducing costs, superior quality of fried product

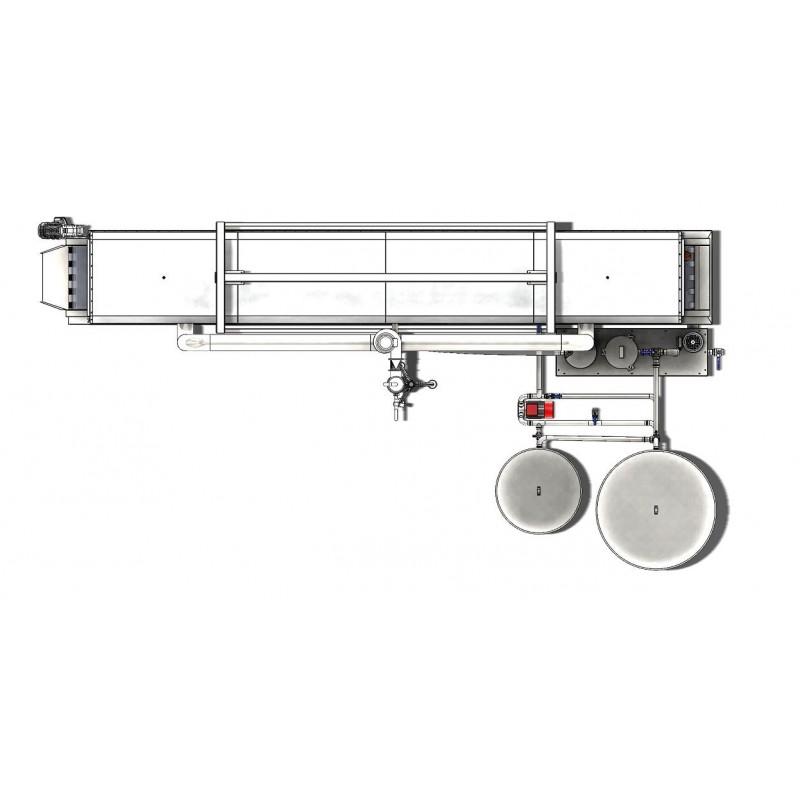

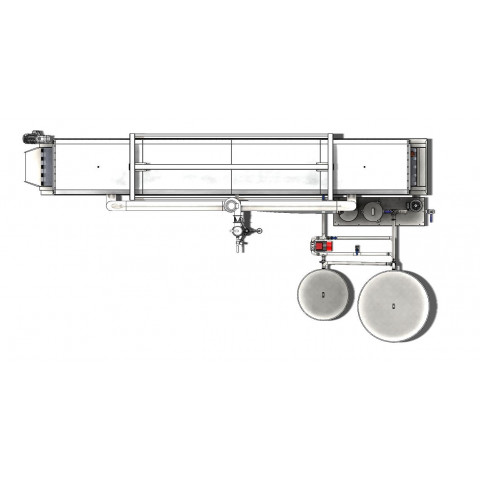

The ShowerFry series of continuous fryers uses the minimal ratio of oil in the whole system to the performance, thereby significantly reducing costs associated with the replacement and disposal of waste oil. The high oil turnover, its intensive circulation and constant filtration, make for a superior quality of fried product, and the preserving of its nutritional properties.

Permanently pure oil a guarantee of a high quality finished product

The entire volume of oil in the Normit continuous conveyor fryers undergoes constant filtration. Smaller product particles are continuously removed using the special multistage stainless steel filters, and the operator visually determines the degree of contamination and the need for filter cleaning. Filter cleaning is performed during operation of the equipment while the oil is still being filtered through the second pair of filters.

Optionally

- additional tank for draining used oil

- tank for oil storage

- oil refill system

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

You might also like

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We have various types of continuous or batch fryers. Just tell us what kind of product you wish to fry and we will help you choose the right deep fryer.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

Our continuous fryer is designed for frying cutlets, potatoes, meatballs, croquettes, fish, vegetables and many other products. Working volume up to l: 300 l.

- Material: Stainless steel

- Heating power, kW: 40

- Principle of operation: Continuous mode

- Oil volume: 300 l

- Voltage: 380-400V

The compact tabletop paddle fryer can be used for the production of a variety of snacks, including vegetable and fruit chips fried in oil. It is also suitable for frying extruded chips and snacks.

- Innovative design: a compact continuous paddle fryer for professional kitchens

- Intensive three-zone heating using thermal controllers for each heating element

- Specially designed blades along the entire length of the fryer to immerse the product in oil

- Frying time can be set from a few seconds up to an hour

- Product agitation system during loading for product separation

- Thermal insulation of the working body to reduce heat loss and for safer operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Voltage: 380-400V

USED PRODUCT - 1 LEFT IN STOCK

Continuous deep fryer OIL MINI is designed for gastronomy and catering. It is ideal for deep frying of meat, ravioli, meatballs, seafood, poultry and vegetables. It ensures continuous frying and stable frying results. The heating elements are located in a double thick aluminum bottom, the so-called "sandwich bottom", which prevents the product from sticking to the heating elements and burning, thus you can use the oil many times more!

Basic price - 5960Ōé¼. The possibility of adding an oil spraying / pouring module (combifry), for an additional cost of 3980 Ōé¼ (RECOMMENDED OPTION)

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode

This commercial frying pan with mixing and a tilt function is designed for frying, saut├®ing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This industrial deep fryer, with its independent support structure, is designed for batch deep-frying of various products, such as potatoes, vegetables, meat, prepared and semi-finished foods, snacks, and baked goods.

- Even frying: The basket ensures complete and uniform immersion of the products in oil.

- Increased productivity: By swapping baskets, loading and unloading can occur simultaneously, boosting efficiency.

- Fast cooking: Intensive and even heat transfer from the bottom electric sandwich heating ensures rapid and uniform frying.

- Mobility: The unit is easy to move and position as needed.

- Ease of maintenance and cleaning: Designed for simple upkeep and hygiene.

- Heating: Electricity

- Material: Stainless steel

- Volume: 50l/ 100l

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The continuous production line for deep-frying and the subsequent cooling of semi-finished products includes:

- modular deep fryer┬Āwith the option of choosing the conveyor type: a┬Āsecondary conveyor for forced immersion┬Āof the product in oil or a┬Āconveyor with paddles┬Āfor frying light floating products, such as chips;

- stainless steel table┬Āunder the deep fryer with the option of installing an oil container and an┬Āoil filtration system┬Āinside it;

- cooling conveyor for removing excess oil and surface cooling of the product after frying it in the deep fryer.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 400 mm

- Voltage: 380-400V

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.┬Ā

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine