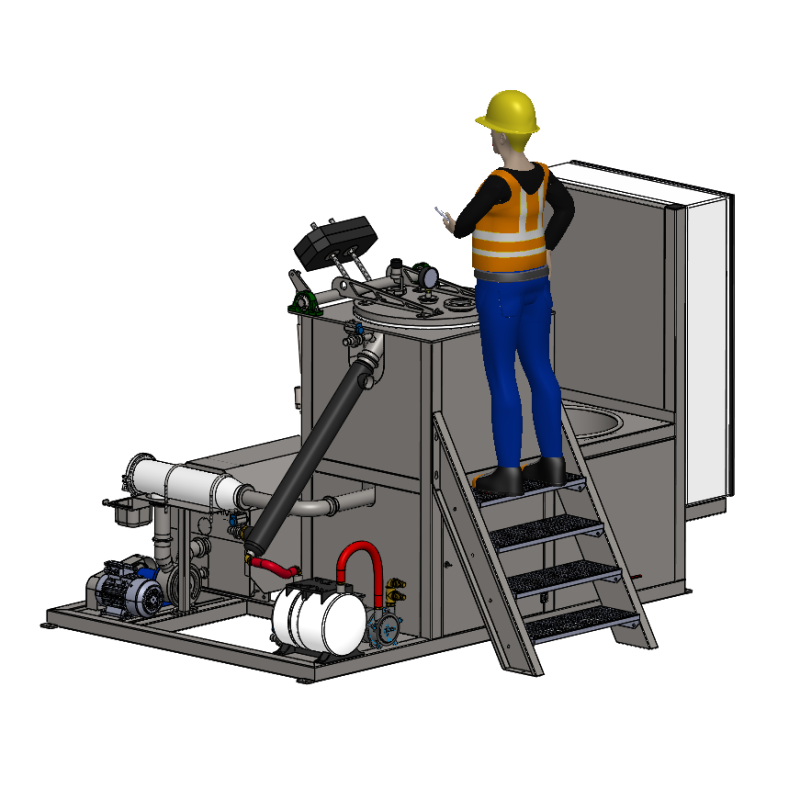

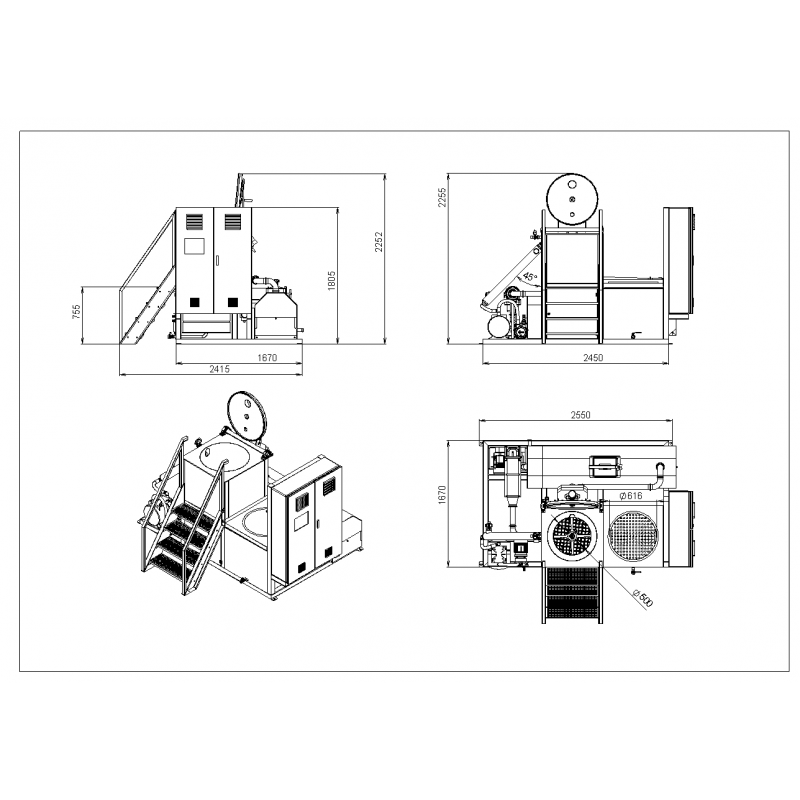

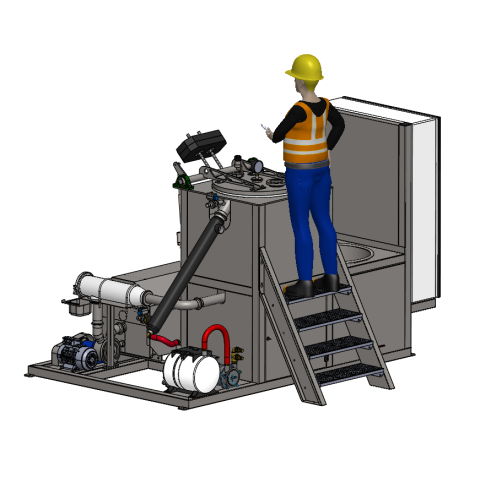

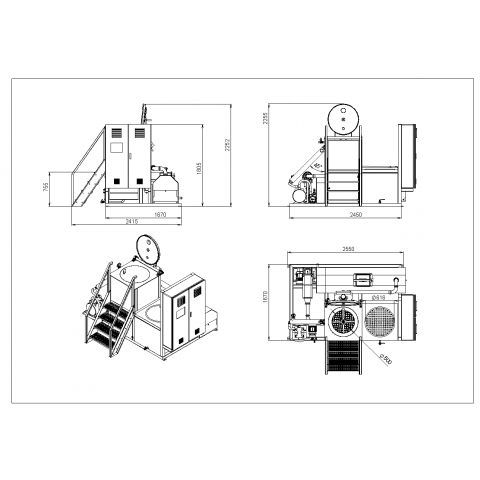

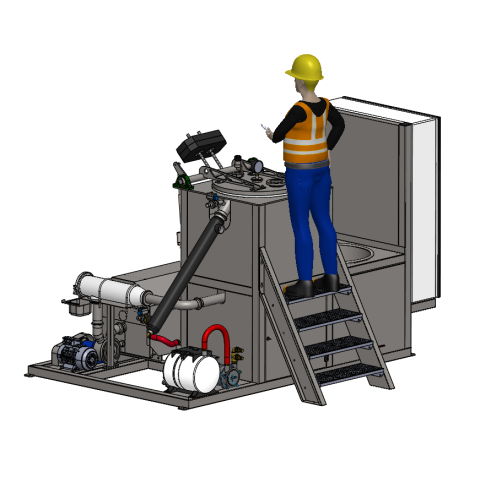

Vacuum fryer with a blancher VFB

The VFB vacuum fryer with a built-in blancher is intended for drying and frying a wide range of products as well as for the production of chips and crisps from potatoes, carrots, onions, celery, parsley, beetroot and many other types of fruits, vegetables, and different snacks made out of meat, pork skin and fish.

Vacuum fryer with a built-in blancher VFB

The vacuum fryer with blancher VFB is designed to handle a wide range of products such as: potatoes, carrots, onions, celery, beetroot and many other fruits or vegetables for making crisps, snacks, chips. The versatility of Vacuum frying equipment allows you to experiment with a wide range of food products. It can also be used, for example, to produce semi-finished products as well as products for further processing.

This complex machine is designed for thermal heat treatment of food, including the following processes:

- blanching

- drying

- vacuum frying (snacks, chips)

The complex consists of three working vessels: vessel for blanching, vessel for deep frying and oil storage.

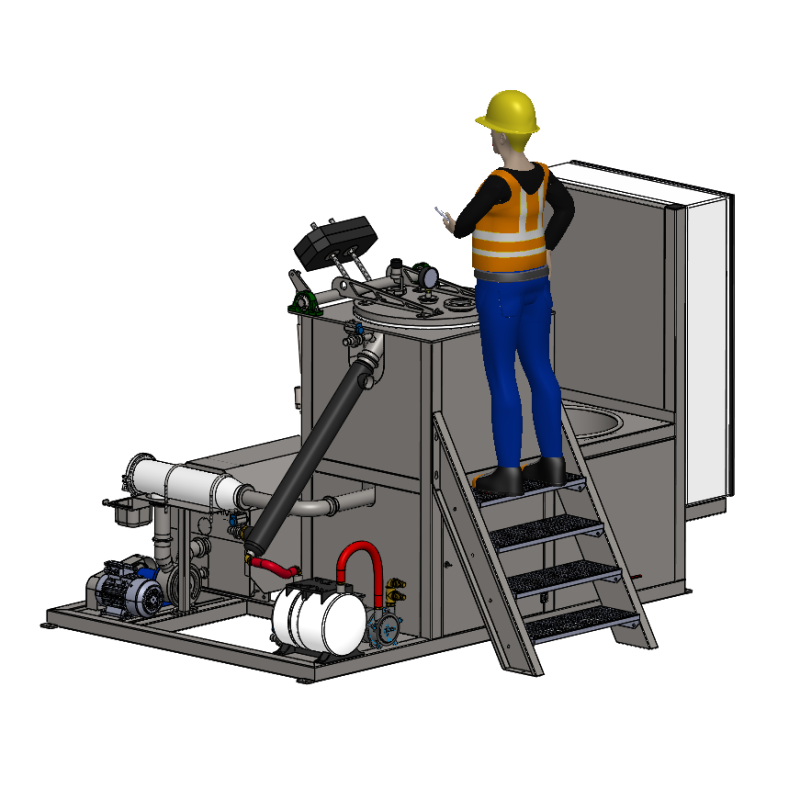

Vacuum frying equipment is fitted with:

- Vacuum pump

- Heating system

- Filter system with an oil pump

- Piping system

- Automatic control system.

The efficiency of a modern thermal vacuum processing system is based on short time and low frying temperature. This technology brings the possibility of producing a healthy product. The result is a crunchy product with low fat content, thanks to the fast processing, which prevents unnecessary saturation of products with oil. In this model, the fryer is equipped with a blanching device. Preliminary thermal treatment of the product in the blancher allows you to preserve the color uniqueness of the product, reduce its volume and increase its elasticity, remove air from the tissues of the product while preserving all the beneficial substances and vitamins, remove microorganisms from the outer product and much more.

Vacuum frying technology

Frying under vacuum conditions (at low temperature) - is a unique and modern way of heat treatment, allowing to achieve unique properties of the finished product. The VFB Vacuum Fryer allows you to fry the product into crunchy product at up to 120 ° C without acrylamide. The fried product does not contain carcinogenic substances and is a healthy alternative to most market snacks. Water is removed under vacuum conditions in a very short time, in addition, the oil does not penetrate into the released pores, complete oil removal is carried out while maintaining the vacuum, allowing the finished product oil content to be reduced to a few percent while in traditional frying at atmospheric pressure, the oil content can reach 30%. Depending on the product and its pre-cooking (blanching, soaking, freezing), it is possible to obtain products with different properties - with a more or less dense structure (puffed snacks), more crunchy or softer with varying color intensity and the like.

The heating system consists of a flow heat exchanger and heating elements. The advantage of this heating system is its high efficiency, and also the possibility of using solid pieces of animal or vegetable frying fat. A special basket divided into four sections allows you to process several products simultaneously. The most important feature of the device is the excess fat removal system, which provides the ability to get a "dry" product immediately after processing. Compact and versatile, the device allows the use of a vacuum fryer even for smaller food product manufacturing, joint catering facilities as well as special experimental laboratories of food product manufacturers.

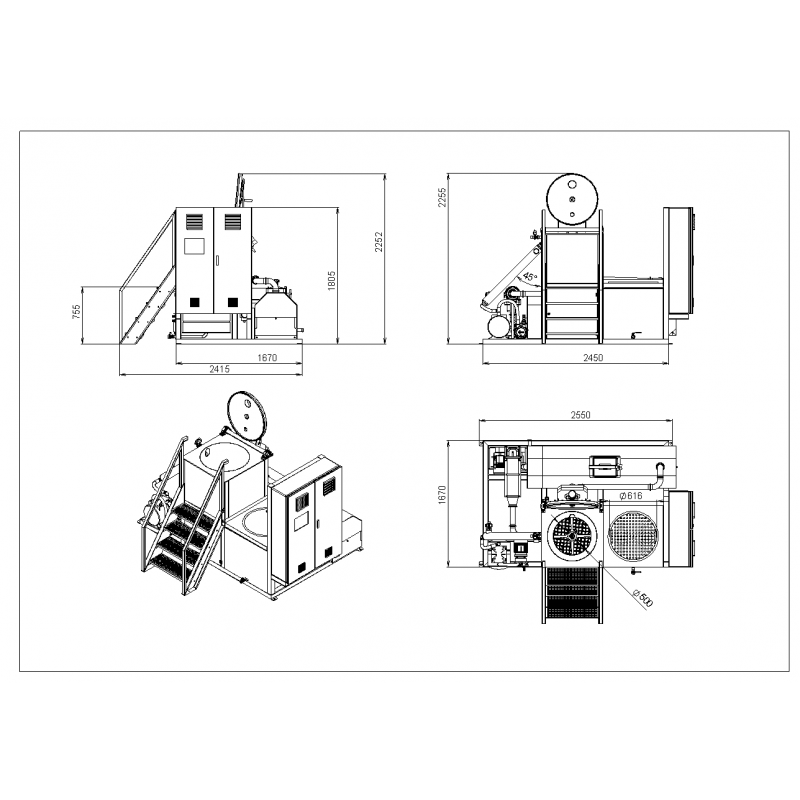

The design of the vacuum fryer with blancher is compact, all units are mounted on one frame and do not need additional fitting and extra control panel. The volume of the blanching chamber corresponds to the volume of the frying pot. The product first passes through the blanching, then immerses itself in the frying chamber. Optionally, the vacuum fryer may be equipped with a rotary jack that allows the product basket to be easily lowered into the blanching chamber, then lifted the water, drain basket and subsequently transferred and immersed in the frying chamber. During vacuum frying, the next batch of product is blanched and drained, allowing a semi-continuous process.

Vacuum fryer is equipped with an automatic PLC control system. The operator and control system has 2 setting modes: automatic, manual. Automatic mode allows simple and safe device control, based on pre-programmed product recipes. The manual mode allows you to check the functionality of the system itself and the units of the device, but also to test new variants of the production recipes. This mode opens the boundaries for your creativity and innovative products, but also for research in the lab environment. Automatic cleaning mode is undoubtedly a big advantage for easier use and maintenance of the vacuum frying equipment.

Technical requirements

- Chilly water for steam condensation system and vacuum pump cooling system. The inlet water temperature should be 5-7 degrees C.

- Compressed air compressor with a pressure of 6-10 bar for the control system of pneumatic valves.

- Connection to the sewage system through grease traps for draining condensate.

- For easy and safe lifting and loading of the basket, it is recommended to provide a lifting device.

- Material: Stainless steel

- Type of the equipment: Individual machine

- Country of origin: Slovakia

You might also like

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.Â

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine

A vacuum frying unit designed for frying vegetables and other snacks at low temperatures, thus making them healthier and less saturated with oil.

- Productivity: 160 kg/15 min

- Material: Stainless steel

- Heating power, kW: 90/ 110/ 180

- Country of origin: Slovakia

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

We offer different types of continuous fryers, let us know which product you wish to fry and we will help you choose the right fryer for your business.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Multifunctional pans function as a frying, cooking, and mixing device in one installation.

- Material: Stainless steel

- Principle of operation: Batch mode

This continuous conveyor deep fryer is a reliable and versatile solution suitable for high-performance frying of a wide range of products by immersing them in hot oil.

- Universal application

- Quick transition for frying new types of products

- Possibility of using special frying modes

- Minimal amount of oil in the system

- Trouble-free oil filtration

- High oil exchange ratio

- High efficiency and productivity with compact design

- Manufactured to the highest quality standards using materials and components made in Europe.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

The automatic donut forming and frying machine is a high-quality device that is suitable for high productivity and daily usage.

- Tabletop system

- Includes a depositing attachment

- Compact design

- Completely out of stainless steel

- Material: Stainless steel

- Principle of operation: Continuous mode

- Weight: 40

- Total power, kW: 3

- Voltage: 220-230V

- Dimensions, mm: 965 x 330 x 650

This commercial frying pan with mixing and a tilt function is designed for frying, sautéing, searing, and cooking foods in small amounts of oil in large batches. An independent support frame with a tilt mechanism ensures easy unloading. The pan features adjustable heating with 6 intensity levels, making it suitable for professional kitchens and small food production businesses.

- Efficient heat distribution for even cooking.

- High performance for continuous batch processing.

- Rapid heating thanks to bottom electric contact heating.

- Mobile design allows for easy movement across the work area.

- Easy cleaning and maintenance.

A pouring fryer is a specialized equipment used in commercial kitchens for frying foods using a continuous pouring method which helps to close down the pores of the product to prevent excessive oil absorption. It offers precise control over the frying process by continuously pouring oil over the food, ensuring even cooking and consistent results.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

Automatic donut fryers are extremely efficient machines designed for easier production of doughnuts.Â

- Material: Stainless steel

- Operation mode: Automatic

- Type of the equipment: Individual machine

The series of Continuous Fryers Pour Oil is the boom in the market of frying and roasting equipment. The new construction designed by our engineers, based on existing practical experience in the production and use of conveyor fryers, provides the best example of environmental friendliness.Â

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

We sell different types of deep fryers, for a price quote or for a free consultation, please contact us by sending a request.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 380-400V

Semi-automatic donut fryers are extremely efficient machines designed for easier donut production.

- Material: Stainless steel

- Operation mode: Semi-automatic

- Principle of operation: Continuous mode

For frying foods in oil, deep-frying, suitable for frying onions, seeds, nuts, vegetable snacks and chips, and other products, including breaded or covered in liaison. Can also be used as an oil separating centrifuge for deep fryer.

- Two in one: a deep fryer and a centrifuge to remove excess oil

- Possibility of frying small and fragile products

- Obtaining a âdry productâ after frying

- Low carbonization of oil due to the cleaning feature after frying

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l/ 90l

- Total power, kW: 11

- Voltage: 380-400V

The compact tabletop paddle fryer can be used for the production of a variety of snacks, including vegetable and fruit chips fried in oil. It is also suitable for frying extruded chips and snacks.

- Innovative design: a compact continuous paddle fryer for professional kitchens

- Intensive three-zone heating using thermal controllers for each heating element

- Specially designed blades along the entire length of the fryer to immerse the product in oil

- Frying time can be set from a few seconds up to an hour

- Product agitation system during loading for product separation

- Thermal insulation of the working body to reduce heat loss and for safer operation

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Voltage: 380-400V

We can help you choose the right continuous fryer suited for your needs.

- Productivity: nuts 400 kg/h

- Material: Stainless steel

- Heating power, kW: 30/ 60

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Weight: 245 kg

- Working Area Width: 250 mm

- Oil volume: 100 l

The price is set based on the basic built-in heating option of 24 kW.

The vacuum fryer is designed for frying foods in oil at low temperatures, allowing for the production of healthy snacks such as vegetable and fruit chips. The vacuum feature enables you to reduce the frying temperature of oil down to 110-120 degrees!

- «Cold roast» is a tasty and healthy method of processing the product

- Drying and frying without caramelizing the sugars contained in the product

- Large frying tank - for processing foods with a higher water content

- Modular heating system which allows you to increase the heating power up to 108 kW (optional)

- Circulating heating of oil through a heat exchanger minimizes oil spoilage and prevents localized overheating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 24

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 30l

- Oil volume: 200l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This industrial deep fryer, with its independent support structure, is designed for batch deep-frying of various products, such as potatoes, vegetables, meat, prepared and semi-finished foods, snacks, and baked goods.

- Even frying: The basket ensures complete and uniform immersion of the products in oil.

- Increased productivity: By swapping baskets, loading and unloading can occur simultaneously, boosting efficiency.

- Fast cooking: Intensive and even heat transfer from the bottom electric sandwich heating ensures rapid and uniform frying.

- Mobility: The unit is easy to move and position as needed.

- Ease of maintenance and cleaning: Designed for simple upkeep and hygiene.

- Heating: Electricity

- Material: Stainless steel

- Volume: 50l/ 100l

- Voltage: 380-400V

Our continuous fryer is ideally used for frying escalopes, potatoes, croquettes and many other products.

- Material: Stainless steel

- Heating power, kW: 72

- Principle of operation: Continuous mode

- Working Area Width: 420 mm

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar