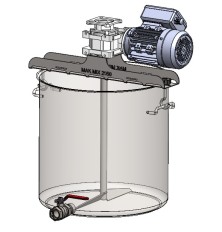

Vacuum mixer with a homogenizer VMG SL 300

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

The vacuum mixing unit provides the highest level of homogenization of the mixture and intensive mixing for a short time and with minimal energy consumption.

Carried out processes:

- Heating, cooling

- Cooking

- Mixing

- Dispersion

- Emulsification

- Homogenization

- Deaeration

Design

The plantŌĆÖs design consists of a thermally insulated cylindrical vessel equipped with a heating jacket for a liquid heat-carrier or steam. Depending on the customerŌĆÖs requirements, the working vesselŌĆÖs design can be welded or fitted with a lifting or hinged lid. The unit is equipped with a frame agitator with a top or bottom drive and built into the bottom of the vesselŌĆÖs homogenizer type rotor stator. The plant in its standard configuration is equipped with a vacuum station and an automatic control system based on PLC.

The product is intensively circulated through an integrated high performance homogenizer and mixed with a horizontal agitator, providing efficient heat transfer between the sides of the vessel and the product. The special shape of the agitator and the placement of the emulsifying homogenizer ensure efficient operation of the plant using only 15% of the total volume of the vessel. Installation of a one or two-level contour of the outer recirculation is possible.

A highly hygienic design of a vacuum emulsifying mixer is made in accordance with the requirements of GMP.┬Ā

Features and options

- Any degree of surface treatment.

- Standard configuration of the plant is designed to work under a vacuum; it is possible to manufacture the plant for operation at significant pressure.

- Any form of agitator on demand, variable speed mixer.

- Ability to install a multi-stage homogenizer to produce super thin emulsions and ointments.

- Possibility for installation of an external high speed homogenizer, which for certain applications may replace the use of a high pressure homogenizer. Feeding of ingredients with a flow meter or tensometric system.

- Device for sanitary sampling during the process.

- When inserting of powdered ingredients directly into the vacuum chamber, a┬Āhomogenizer for complete wetting and uniform distribution of the particulates in the fluid.

- Fixed or rotary CIP balls.

- Interchangeable working elements of homogenizer allow picking the perfect type of rotor and stator for various applications.

- Advanced control system with visualization, temperature control, agitator speed, homogenizer speed, depth of the vacuum pressure.

Technical characteristics:

- Working volume 250 - 270 L

- Agitator drive 1.5 kW

- Length without cabinet 1280 mm.

- The homogenizer is three-shell, the heating is provided by a heat transfer medium, which is supplied from an external source (cooling also from an external source).

- The homogenizer is equipped with two temperature sensors (which are used to sense the temperature of the product and the heating liquid).

- Homogenization is provided by an inline homogenizer with an electric motor with an output of 7.5 kW.

- Mixing of the product is ensured by a paddle full-volume stirrer.

- The agitator is driven by a 1.5 kW motor with a frequency converter.

- The frame has adjustable legs.

- The vacuum homogenizer is equipped with both analog and digital vacuum gauges / pressure gauges (analog range is from -1 to 0 bar) digital (SMC PSE533-M5L) has a range of -101 - 101 kPa.

- The product outlet is secured through a DN 50 pipe.

- The vacuum unit serves for better efficiency due to the fact that it lowers the boiling point of the liquid, which requires less heat for heating and thus less power.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

You might also like

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Vacuum homogenizer VMG M is the ideal solution for the production of pilot batches and the industrial production of a wide range of products of small and medium production. The price depends on the production capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Grinder is used for grinding both fresh meat and food products, such as cheese, fruits.┬Ā

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

A rotating drum unit designed for continuous coating and seasoning operations as well as product saturation with spices and flavor additives, utilized in production lines for chips, snacks, and various semi-finished products.

- Adjustment of the Drum Tilt Angle

- Hygienic design and execution: mirror-polished inner surface of the drum

- Various blade options for gently turning the product (optional)

- Dispensers for dry and wet flavorings (optional)

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 0,25

- Voltage: 380-400V

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

A universal homogenizing module for mayonnaise production. The special compact atmospheric unit with a bottom homogenizer and a circulation system allows to create stable fat emulsion in just a few minutes!

- Compact design

- No dead zones and corners due to the conical shape of the unit

- Powerful bottom inline homogenizer with circulation

- Hygienic design

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 9

Paddle Mixer type is designed for fast and precise mixing for meat-mass production in meat processing factories. Can also be used for mixing products such as spices or tea.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 90/ 150l/ 200l/ 300l/ 400l/ 600l/ 850/ 2000 3000

The mixers are made up of a double-walled cylindrical stainless steel vessel with cavity, with drain hole and 50 cm diameter butterfly valve. The cavity is filled with water which is heated by an electric resistance thermostat. The honey is mixed by blades with a marine propeller profile, adjustable in height along an oblique shaft.┬Ā

- Material: Stainless steel

- Engine power, kW: 0,37/ 0,55/ 1,1

- Principle of operation: Batch mode

- Volume: 100 kg / 250 kg/ 600 kg/ 1000 kg/ 2000 kg

The appropriate mixing equipment for drum processing depends upon the properties of the products and with the available drum opening.

- Type of the equipment: Individual machine

- Voltage: 230 V/ 380-400V

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

A detachable lid with an automatic food stirrer for stainless steel 40 cm pots, suitable for volumes of 50 and 100 liters. An automatic stirrer allows you to mix and stir various products, including during thermal processing. The type of mixing device can be additionally selected depending on the required process.

- Professional industrial single-phase motor for 220-230 Volts

- The control is located directly on the motor housing or on the drive cable

- Easy and simple installation and fixation of the lid on the pan

- Suitable for standard 40 cm pots with a capacity of 50 or 100 liters

- The lid and stirrer are made entirely out of stainless steel

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Voltage: 220-230V

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia