Frozen block flaker FBF600

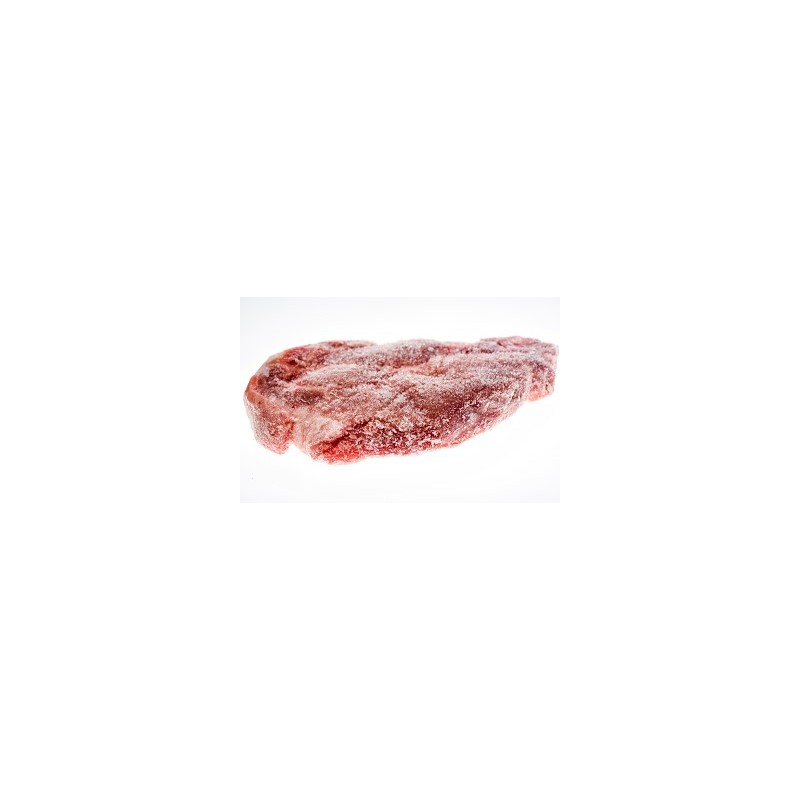

The block cutter is designed for chopping frozen blocks of meat, fish, poultry, meat by-products, juice, butter or margarine without prior defrosting. This is a convenient and quick method of preparing the products for further processing, which saves time and reduces the likelihood of product contamination.

- Efficiently slices the product into thin layers while preserving its texture

- Safe pneumatic feeding of the product into the grinding section

- Special fixation system for the product container during unloading

- Low product losses during processing

- A powerful blade drive

Block cutters are used in meat and confectionery production, as well as in the manufacturing of juices and semi-finished products. They are often used due to their significant time-saving capabilities and their contribution to maintaining the hygienic standards of food products.

Slicers, using special knives, can chop frozen blocks of products such as:

|

|

|

|

|

|

|

|

|

|

Advantages:

- Versatility. The basic version is equipped with knives for cutting blocks into thin chips, with a thickness of 2 mm, excellent for slicing and crushing offal, for example, liver for the production of sausages. Depending on the product, the machine can be equipped with different types of knives.

- Safety. When the lid is opened, the rotor drive equipped with knives is automatically switched off. The blocks are fed safely using a pneumatic roller to minimize operator risk.

- Grinding is carried out practically without losses. The crushing system and the angle of the knives are guaranteed to direct the product towards unloading. Pieces of the product do not remain on the surfaces and do not fly away; the sidewalls and special curtains┬Ā help to prevent this.

- The installation is equipped with a system for fixing rolling trolleys under the unloading hopper, making it convenient and safe to operate.

Basic version

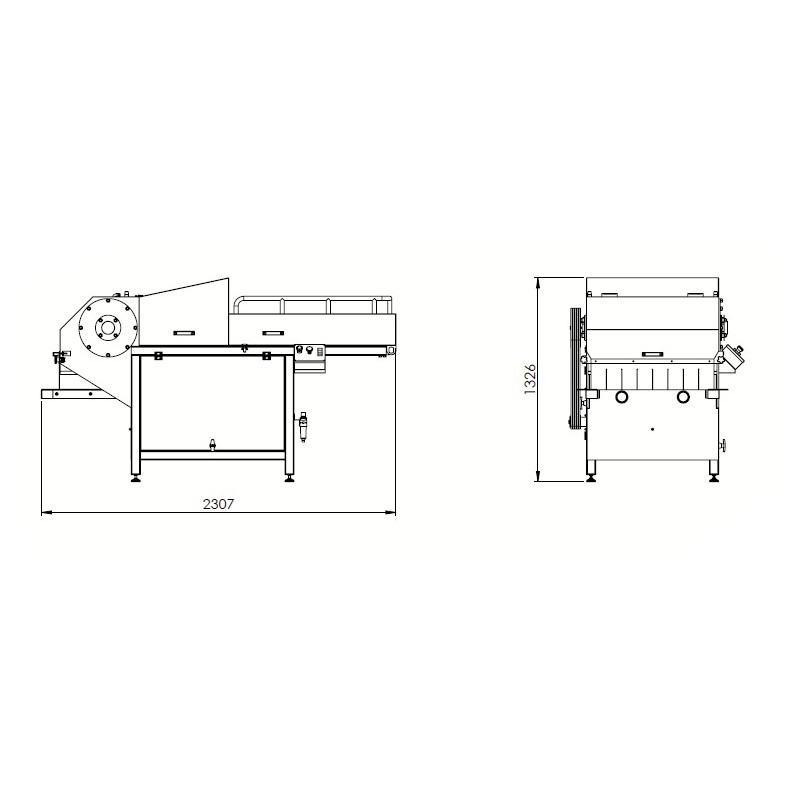

It consists of an installation with a reinforced stainless frame structure, equipped with a loading system for frozen blocks with a working width of 600 mm, a BIN container fixation system for unloading, a grinding section with an 11 kW rotor drive, on top of which knives with blades sharpened on both sides are installed. The control system is located directly on the body of the unit.

Technical requirements:

- Compressed air drive with a pressure of 6-10 bar

Options:

- Replacement of knives at customer's request

- "Quiet" compressor for compressed air

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Width: 600 mm

- Total power, kW: 11

- Voltage: 380-400V

We offer different types and capacities of meat flakers.

- Material: Stainless steel

- Engine power, kW: 5,5

- Operation mode: Semi-automatic

- Country of origin: EU

Compact size vegetable/cabbage cutting machine, that is intended for vegetable shredding, slicing, grating and julienne stick cutting.

The price depends on the production capacity.┬Ā

- Productivity: 1000 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

The high-performance slicing and dicing machine can function as a standalone unit or be integrated into a production line.

- Can process large products - sweet potato, lettuce, root vegetables

- Large selection of replaceable knives - different sizes of the final product

- Material: Stainless steel

Manual cutter for cutting potions of fresh cured meats with interchangeable eccentrics to obtain different sausage lengths up to a maximum of 280 mm. Works with any type of casing.

- Productivity: 100-400 psc/h

- Material: Stainless steel

- Principle of operation: Continuous mode

Semi-automatic tying machines are designed for tying sausages and other meat products. Suitable for meat producers or small butchers.┬Ā

- Material: Stainless steel

- Weight: 42

The cutter is designed for cutting into cubes, stripes or slices.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

- Voltage: 380-400V

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Productivity: 120 kg/h

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

The cutting machine is designed for slicing, shredding and grating fruits and vegetables.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Dimensions, mm: 602x488x1581

Cutter for french fries with an automatic hopper. Approx. 25 kg of French fries 12mm per minute. Cutting blocks are ordered separately.

- Productivity: 1500 kg/h/

- Material: Stainless steel

- Engine power, kW: 0,37

- Dimensions, mm: 360x670x560

The CAF 65 cabbage shredder is designed for large processing plants, for a daily production of about 60 tons.

- Engine power, kW: 2,2

- Principle of operation: Continuous mode

Vegetable cutter with adjustable cutting thickness, blades very easy to replace which makes them cost-effective.

- Productivity: 500 kg/h/

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

- Productivity: 30 kg/h

- Material: Stainless steel

- Voltage: 220-230V

Fully automatic machine for making kebab and brochettes by skewering meat on a stick with a maximum production capacity of 1500 pieces per hour.

- Productivity: 1500 psc/h

- Principle of operation: Continuous mode

- Weight: 120

- Voltage: 220-230V

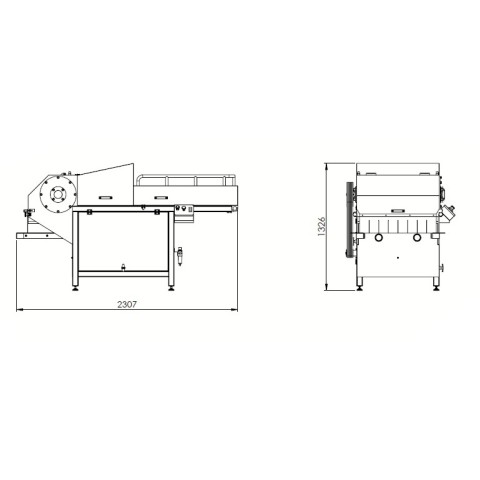

The meat flaker is an automatic machine for cutting frozen blocks of meat into slices.

- Productivity: 2500 kg/h

- Material: Stainless steel

- Engine power, kW: 9,2

- Principle of operation: Continuous mode