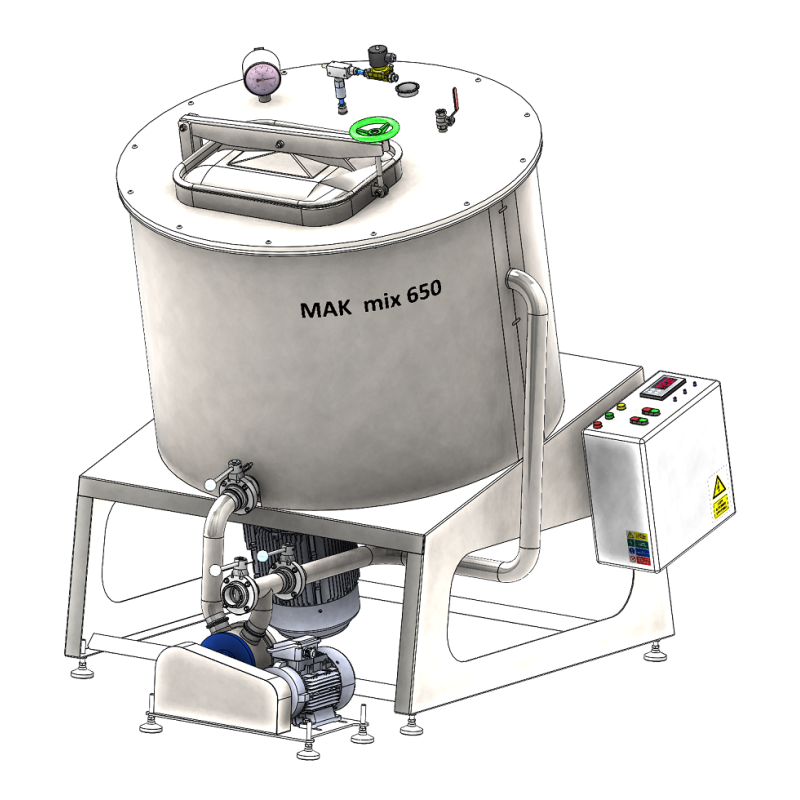

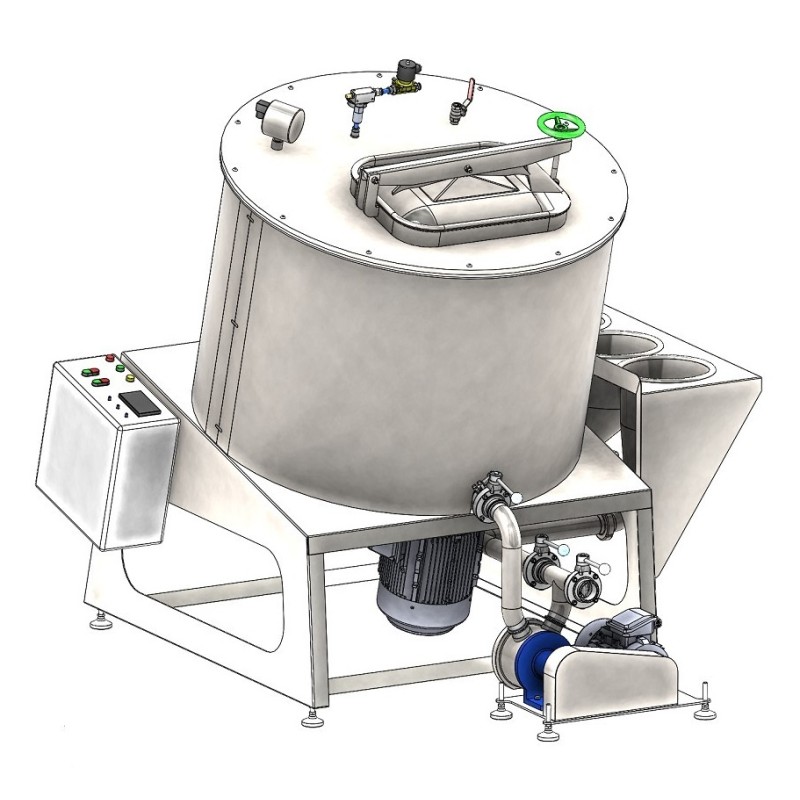

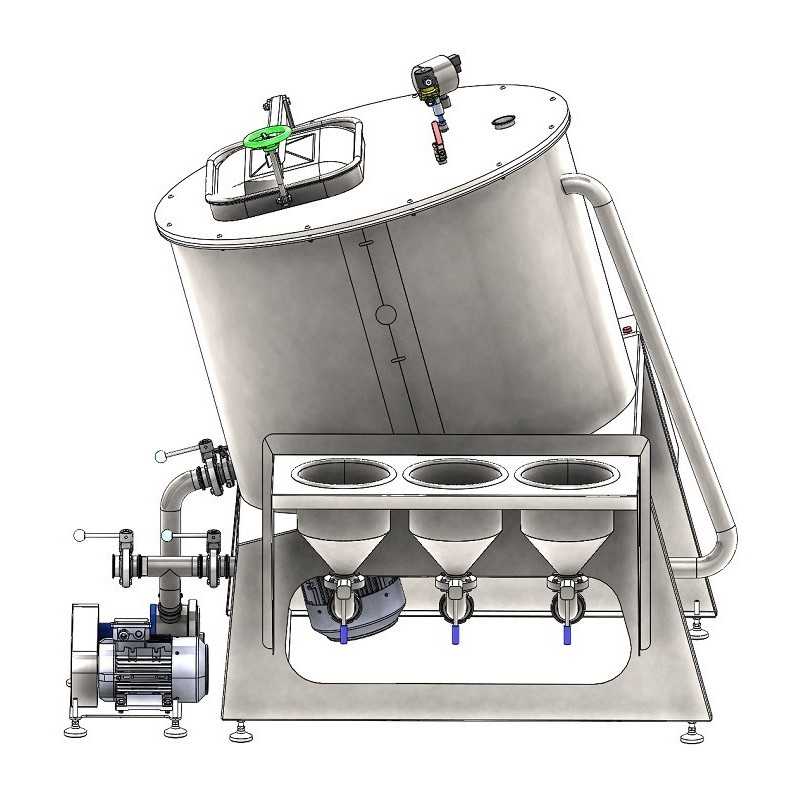

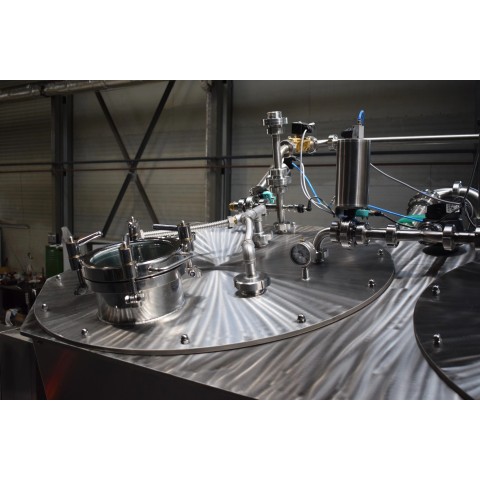

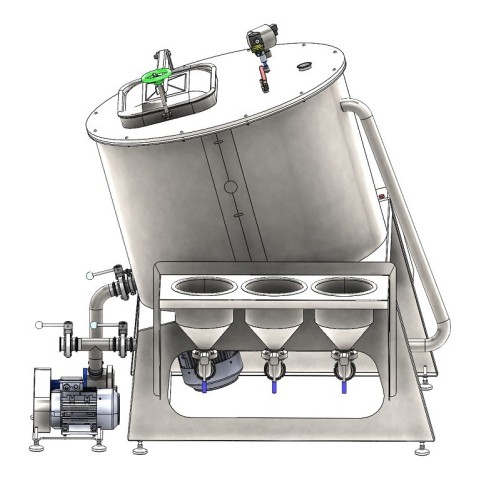

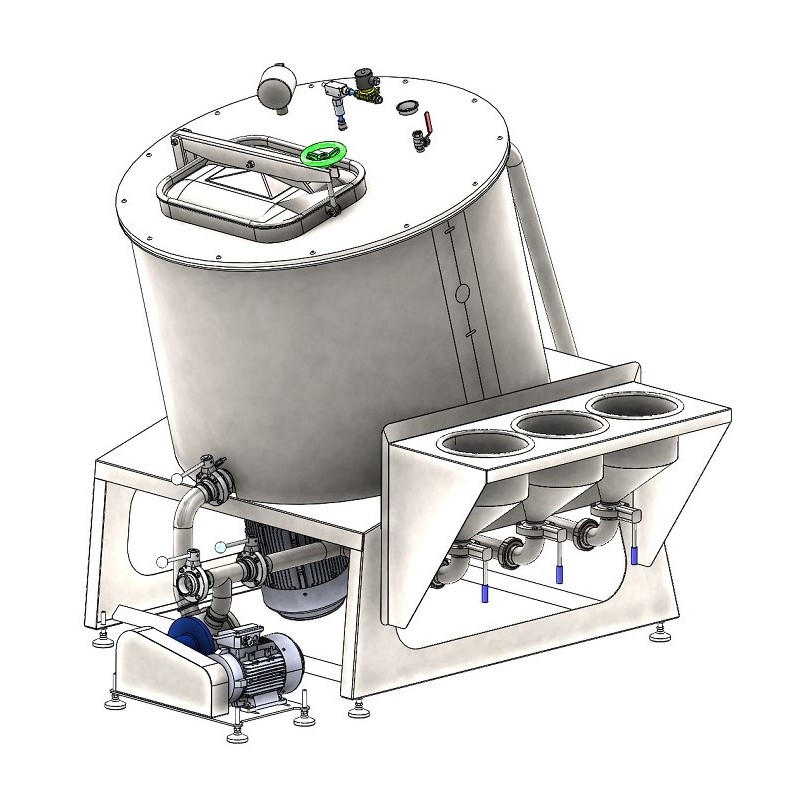

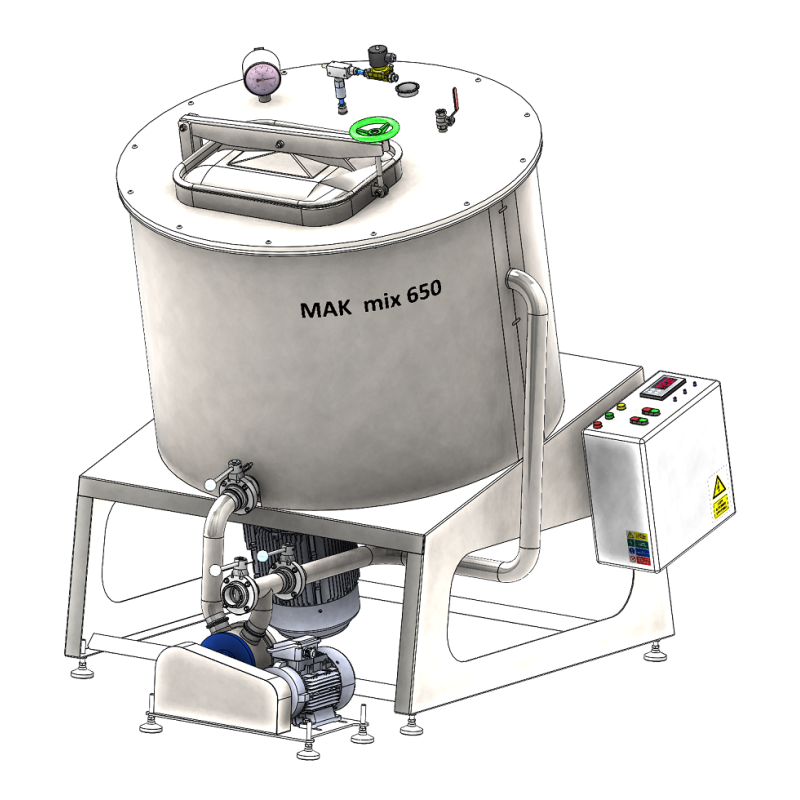

Vacuum mixer MakVacMix 350-650

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

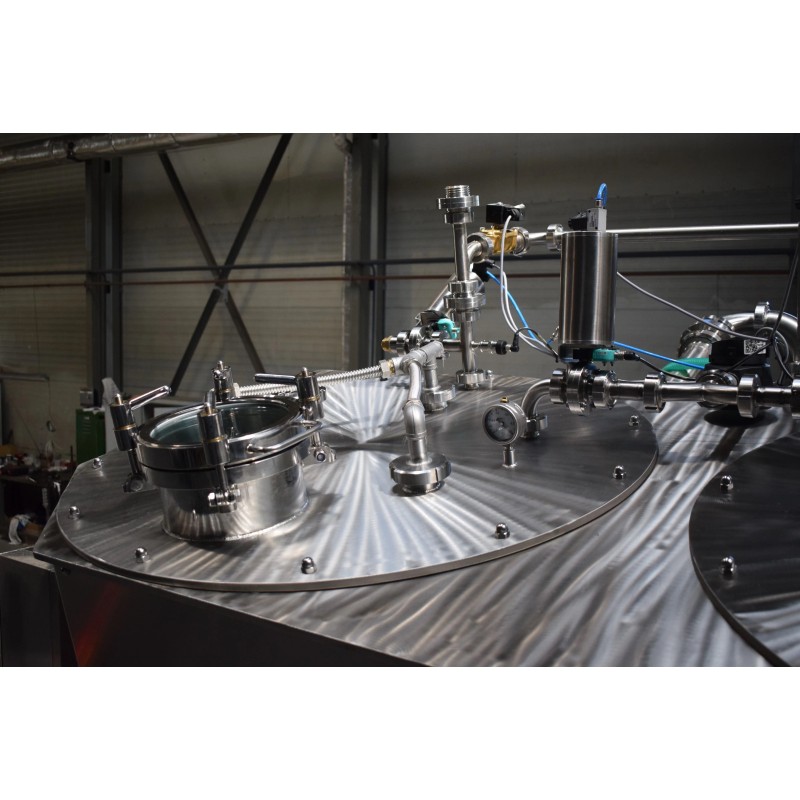

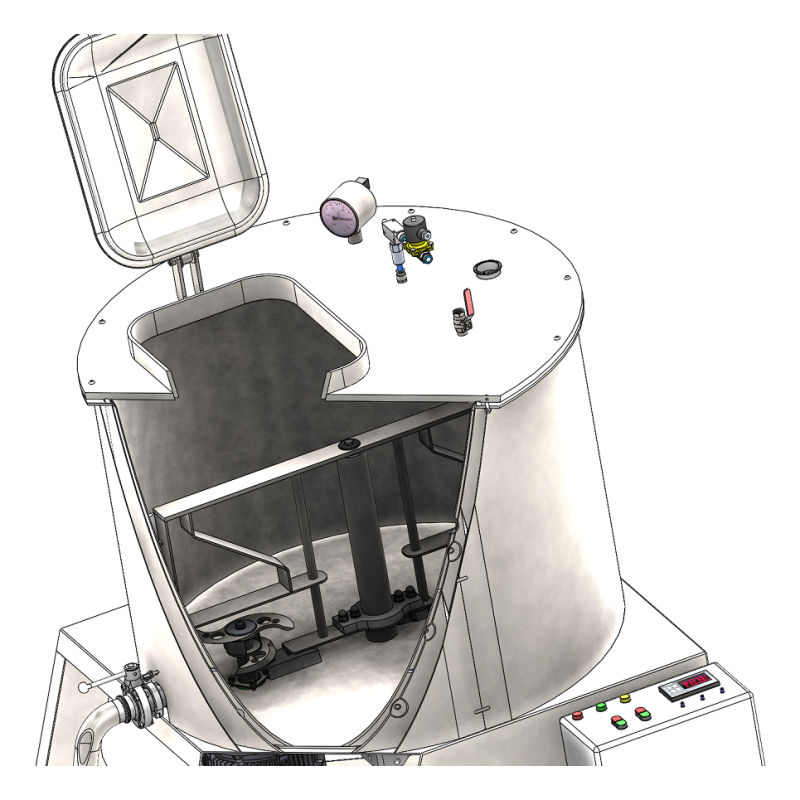

- Built-in jacket for the bottom and walls of the unit.

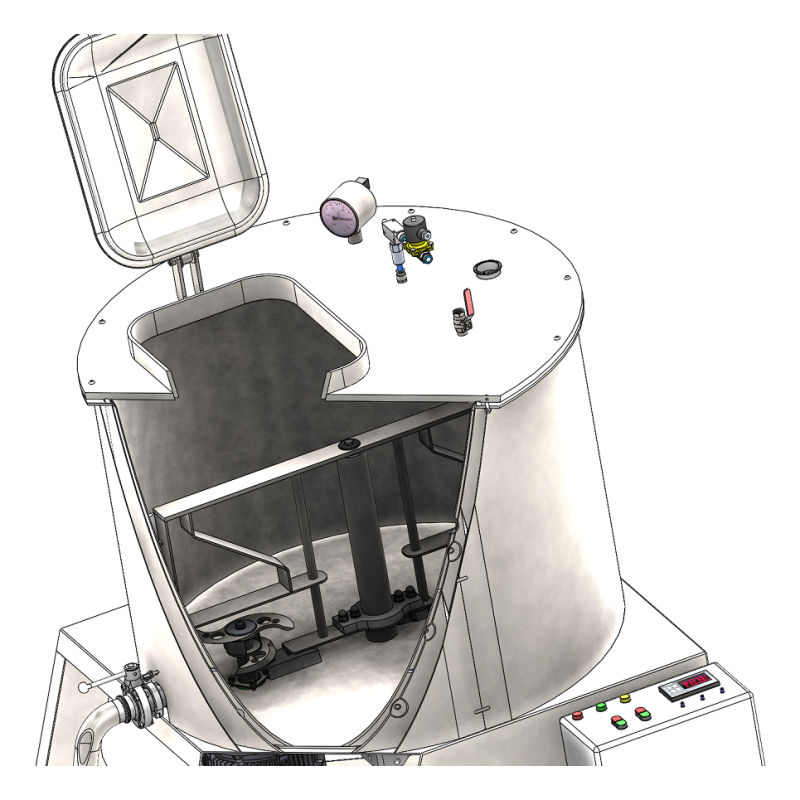

- Cutter knives with a powerful electric drive

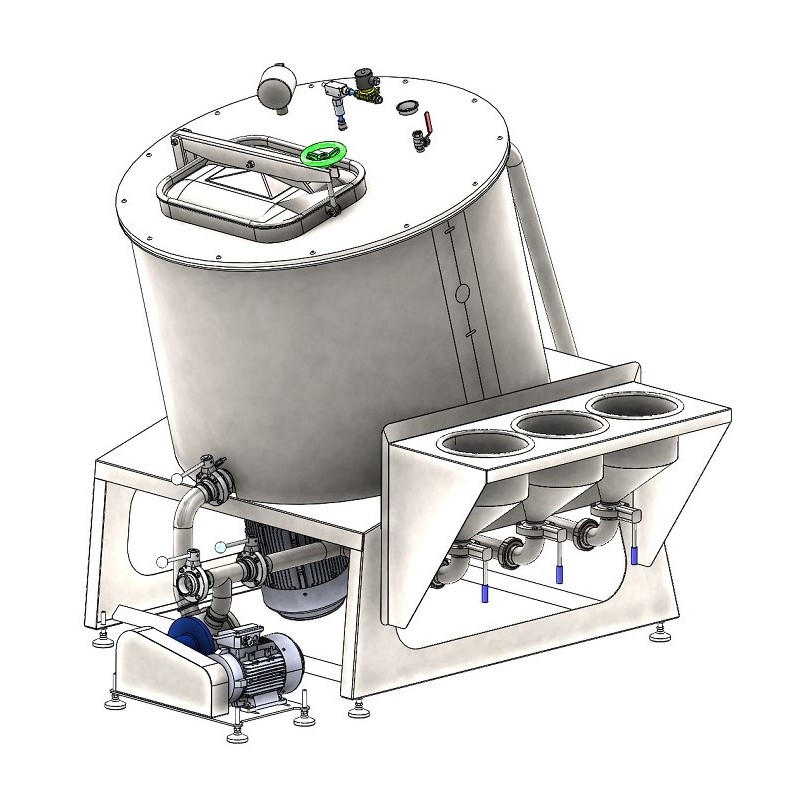

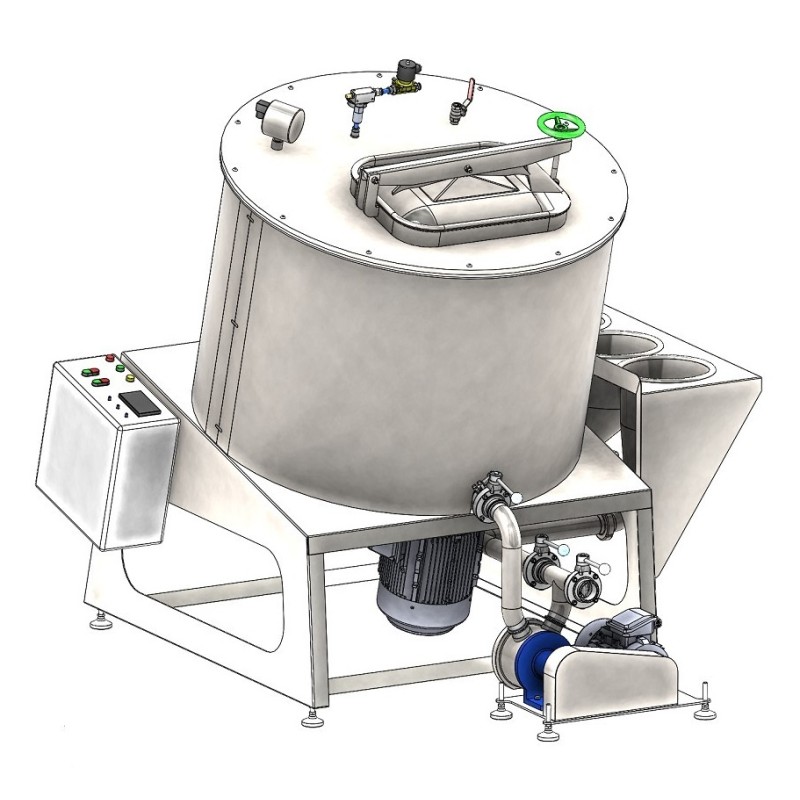

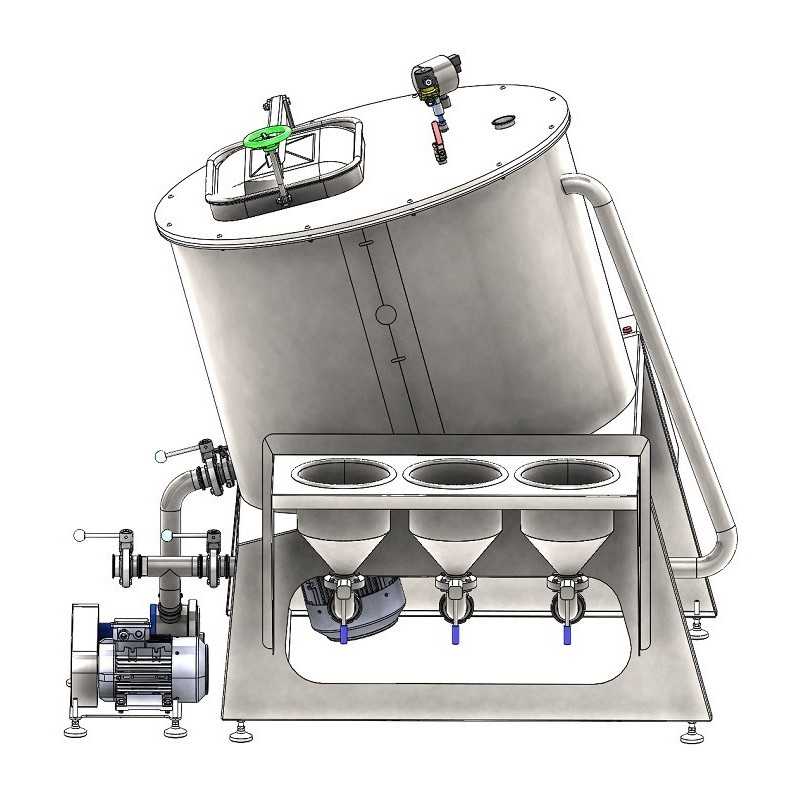

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

A unique feature of the system is the ability to replace the cutter knives installed in the lower part of the inclined reactor with a bottom homogenizer of the Ultra Shear type, enabling the creation of stable emulsions on a water-fat base.

A multifunctional vacuum mixer is often utilized for grinding, mixing and homogenizing, to obtain homogeneous masses of various products, it can be used for products such as:

|

|

|

|

|

|

|

|

Advantages:

- The vacuum reactor allows for thermal processing under vacuum conditions, which is important for the production of heat-sensitive products that lose their nutritional value at higher temperatures.

- Depending on the vacuum source which is available as an option, it is also possible to vacuum cool or vacuum the product to reduce pathogens in air bubbles created when chopping or beating the product.

- The vacuum also serves to maintain the sterility of processing procedures, reducing the potential for contamination. This is highly important both in the production of food items and in the manufacturing of toothpaste, gels, and creams.

- Mixing is 20% more efficient thanks to the inclined design of the structure. The cutter knives are installed at the lowest hydraulic point, ensuring high-quality product grinding. The mixing device and cutter knives facilitate "internal" circulation of the product, thereby achieving high product homogeneity.

- The mixer can be retrofitted with an external forced circulation circuit to increase the intensity of heat transfer, the pump of which also facilitates quick and convenient unloading of the product from the installation.

Processes:

|

|

|

|

|

|

Basic version

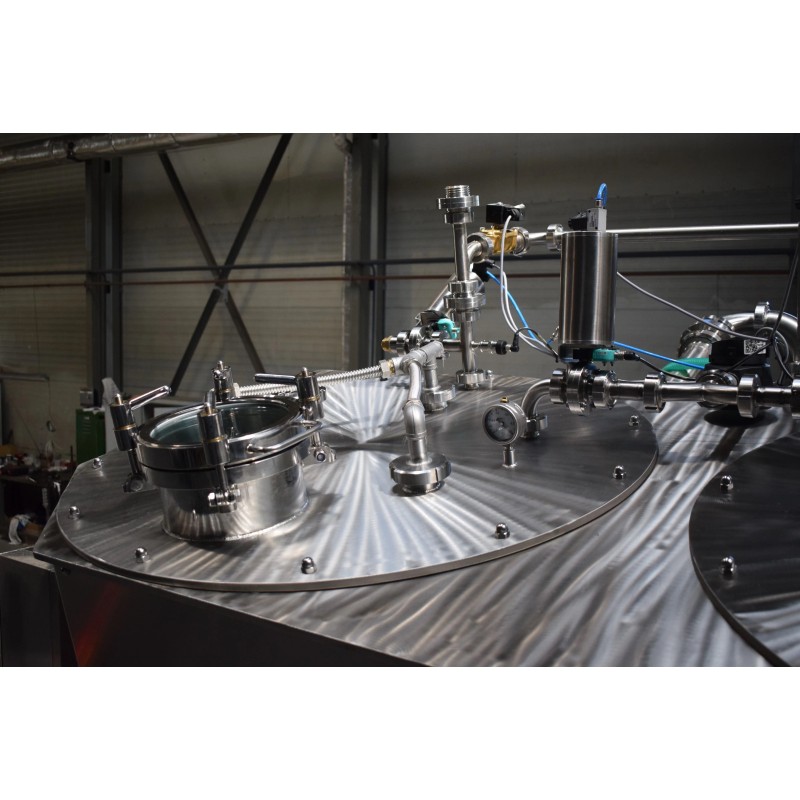

The basic version comprises an inclined vacuum reactor with a jacket for the coolant (heating or cooling medium supplied from an external source). In the initial version, it is equipped with cutter knives and a mixing device. As a vacuum source, the basic version uses an ejector powered by compressed air from an external source (the compressor is not included in the delivery). Product loading can be done through the top hatch of the unit or, optionally, using a pump through the outlet valve. The maximum vacuum depth is 0.8 Bar. In the basic version, the vacuum is not adjustable; as an option, a vacuum gauge can be installed to monitor and maintain the specified vacuum depth. The basic control version includes a thermal controller with a temperature sensor in the product and a controlled coolant supply valve. Frequency converters for cutter knives and the mixing device allow for the adjustment of the operating speed.

The coolant (water, steam) can be supplied into the installation's jacket. For certain coolants, the pressure at the entrance to the jacket can reach a maximum of 0.5 Bar; it is advisable to install a pressure reducer.

Options:

- Vacuum oil pump - recommended for creating a deep vacuum and vacuum cooling (to use the vacuum cooling function, it is recommended to select an additional option - a system for removing and condensing secondary steam).

- Water ring vacuum pump - recommended for quickly creating a vacuum, it requires a cold water supply (cold water connection) to operate.

- External forced circulation circuit with a self-priming pump for convenient and quick product unloading.

- Ultra Shear homogenizer - a kit for replacing cutter knives.

- Maintaining and adjusting the vacuum.

- A System for the removal and condensation of secondary steam.

- Sources of coolants (hot water supply, ice water stations).

- A system of cones with pipelines as well as control and shut-off valves.

- Automatic component dosing system based on a touch screen controller.

- Vacuum loading through a specialized pipe with a hose for vacuum filling of the container through the bottom valve to the level of the working fluid.

- Quiet compressor for compressed air at 6-10 Bar.

- CIP heads (nozzles) for washing are made out of food-grade stainless steel; as an additional option, rotary nozzles can be ordered to cover all surfaces of the container, including the opening hatch of the equipment.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

You might also like

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The continuous rotary mixer is a professional solution for mixing, stirring powder and bulk materials.

- Allows precise dosing of components during continuous mixing

- Low energy consumption with high processing volumes

- Made entirely out of stainless steel

- Adjustable working drum tilt

- Special blades for mixing bulk and fragile materials

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A honey homogenizer is a batch-type device designed to improve the product's structure and organoleptic properties. It ensures a uniform consistency and stable texture of honey.

Homogenization is a processing technology that makes honey flowable and uniform, as well as inhibits crystal growth, thus meeting the needs of producers and consumers. The design, size, and angle of the rotary auger achieve a high level of homogenization, which also reduces raw material processing time.

- High level of homogenization, aimed at increasing stability and improving the honey's structure without altering the product's flavor.

- No dead spots or corners due to the inclined bottom of both the working tank and the auger mixer.

- The working tank is equipped with a jacket and a built-in water heating system.

- Large-diameter outlet valve installed at the lowest hydraulic point.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 4/ 7

- Loading, kg: 500/ 1100

Running of various production processes such as cutting, mixing, crushing, refining and emulsifying different types of product in a single unit.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 359 kg

- Volume: 150l

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

ACM mixing tank is intended for efficient cooling, heating, tempering and storing of mayonnaise, sour cream, chocolate, oil and similar products after their production.

- Material: Stainless steel

- Principle of operation: Batch mode

Highly efficient production of a high viscosity pharmaceutical and cosmetic products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Geometric volume: 500 l/ 800 l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

This versatile 300 liter planetary mixer is a professional food processing equipment used for mixing, kneading, and blending ingredients in various culinary applications. It features a unique mixing action where the beater rotates on its axis while also revolving around the bowl, ensuring thorough and consistent mixing of ingredients.

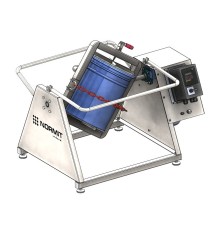

Barrel mixers are used to mix a wide range of loose and granular products in a shipping/barrel container. The available mixer models are suitable for the following volumes:

ConMix 20 - 20-30 liter standard drums with a diameter of 316 mm, adjustable frame structure height

ConMix 75 - 48-65 liter standard barrels with a diameter of 400 mm, adjustable frame structure height

- It is possible to use standard food containers ranging from 20-65 liters

- Easy control via a frequency converter as a stand-alone control panel

- Safe operation thanks to a roll bar with a position sensor

- Engine power, kW: 0,37/ 0,55/ 1,1

- Volume: 20l/ 75/ 100l

The coating machine is designed for uniform application, impregnation of oil and fat mixture, dyes and flavors, enzymes, vitamins and other additives, various products with a high level of hygiene.

- Material: Stainless steel

- Engine power, kW: 2,2

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

The salt dissolving equipment is designed for preparing high-quality marinades, brines with crystal salt, as well as various syrups with the addition of flavor enhancers and essences in small quantities.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 250l/

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

The tank is designed for heating and mixing chocolate, butter, margarine, honey and similar products.

- Material: Stainless steel