Analogue refractometer for measuring viscosity

Analogue refractometers offer an efficient, accurate, and easy-to-use solution for measuring Brix levels and ensuring product quality in the food industry.

Analogue Refractometer for Measuring Brix and Viscosity in Food Products

An analogue refractometer is a simple optical instrument used to measure the Brix level (sugar concentration) or approximate viscosity of various food products, including honey, fruit juices, syrups, dairy, and other liquid-based foods. This handheld device provides quick and accurate readings, making it an essential tool for quality control in food processing, beekeeping, winemaking, and other industries that rely on consistent composition of products.

How does a Analogue Refractometer Work?

An analogue refractometer operates based on the principle of light refraction. When a liquid sample is placed on the instrumentŌĆÖs prism, light passing through the sample bends at an angle depending on its density. The refractometer then converts this refraction angle into a Brix percentage (┬░Bx) or another relevant scale, such as refractive index (RI).

To use the refractometer, follow these simple steps:

- Calibration: Before measurement, the refractometer should be calibrated using distilled water to ensure accuracy. A few drops of water are placed on the prism, and the calibration screw is adjusted until the reading is at zero.

- Sample Application: A small amount of the liquid product (e.g., honey, juice, syrup) is placed on the prism surface.

- Light Source & Reading: The user closes the transparent cover plate and looks through the eyepiece towards a light source. The Brix scale or measurement reading appears clearly within the viewing field.

- Cleaning: After measurement, the prism should be cleaned with a soft cloth to ensure accuracy for future readings.

Common Uses in the Food Industry

- Honey Production: Beekeepers use refractometers to measure moisture content in honey, ensuring it meets industry standards for stability and shelf life.

- Juice and Beverage Industry: Ensures the correct sugar content in fruit juices, soft drinks, and alcoholic beverages.

- Dairy and Condensed Milk Production: Helps determine lactose levels and consistency in dairy-based products.

- Syrups and Sauces: Measures sugar concentration to maintain product consistency and prevent crystallization.

Advantages of an Analogue Refractometer

- Simple and Portable: The handheld design allows for easy, on-the-go use in food processing facilities, farms, or production sites.

- Fast and Reliable Results: Provides immediate readings without requiring complex digital setups or power sources.

- Cost-Effective: More affordable than digital alternatives while still offering high accuracy for routine testing.

- No Batteries Required: Functions entirely on optical principles, making it reliable in any setting.

- Versatile Applications: Suitable for a wide range of food products, including honey, jam, soft drinks, beer, dairy products, sauces, and even industrial applications like lubricants and coolants.

- Type of the equipment: Optional equipment

You might also like

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

Within seconds, the device measures the refractive index of the sample and converts it to % of solids using the concentration unit.

The refractometer is ready for use after a simple user calibration with deionized or distilled water.

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

The paddle module for the 400/1100/12 Universal Tabletop Modular Fryer is a conveyor with specially curved paddles for gentle frying of fragile and light foods.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

Designed for the demanding requirements of the beer and beverage processing industry, this pressure suction food hose offers exceptional safety, durability, and compliance with international food standards. It is ideal for the transportation of high-quality raw, pasteurized, and organic beer, as well as a variety of other beverages, including wine, soft drinks, and alcoholic drinks.

- Type of the equipment: Optional equipment

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

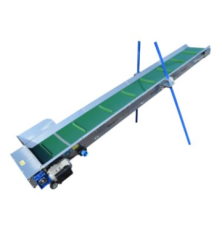

Variable belt conveyor with wide use not only in the food industry. The length of the conveyor can be selected from 2 to 6 m. The width of the belt is 200 and 400 mm.

- Engine power, kW: 0,75

- Principle of operation: Continuous mode

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts