Refractometer for jam cooking equipment

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

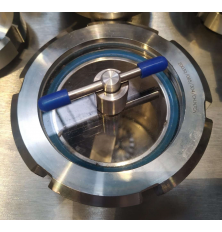

This industrial refractometer provides accurate Brix measurements during production.

It enables continuous monitoring of the cooking process, ensuring consistent product quality and facilitating process optimization. The refractometer can be installed directly into any type of cooking equipment to monitor batch processing and ensure consistent quality of the final product. With a measurement range of 0-100 Brix, it provides real-time control via Ethernet or 4-20 mA output signals. These signal can be used for quality control, allowing immediate corrective action if Brix levels deviate from the desired range.

By eliminating the need for batch sampling and offline analysis, the refractometer improves product uniformity, improves quality and optimizes sugar use. Typical measurement ranges include 10-70 Brix for making jam and 50-85 Brix for marmalade production, with process temperatures ranging from 70 to 90 ┬░C (158 to 194 ┬░F).

The refractometer is designed for installation in large pipes, tanks, cookers, evaporators, crystallizers and cooking kettles. Its long probe, which is compatible with common tank bottom flanges, allows installation depths of up to 170 mm. The flush-mount option allows installation in tanks with mixers and scrapers. The refractometer supports CIP and SIP cleaning.

This model is Indigo compatible, offering advanced features such as data logging, wash control, measurement customization, diagnostics and service updates.

Refractive Index (nD): 1.3200-1.5300 (corresponding to 0-100 Brix).

- Type of the equipment: Optional equipment

Optional module for the 400/1100/12 universal tabletop Modular Fryer - Pressure Conveyor for frying foods that require forced immersion in oil.

- Material: Stainless steel

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

The IBC container insulation cover is designed for use in ice water stations with IBC containers to maintain the cold coolant at a set temperature.

- Allows you to reduce energy costs of the refrigeration machine - chiller

- Protects from short-term fluctuations in ambient temperature, reflects sunlight (up to 97%)

- The cover is easy to install, with valve holes are installed with hook-and-loop fasteners (Velcro)

- Type of the equipment: Optional equipment

Additional option for the VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

A hot oil filter for continuous industrial tabletop fryers allows you to quickly and effectively filter oil immediately after the frying process.

- Hot oil filtration - oil temperature up to 200 ┬░C.

- Optional filter material - paper, stainless steel

- Material: Stainless steel

- Country of origin: Slovakia

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

A large three-section basket for vacuum fryers, cooking kettles and other batch processing equipment.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A frequency converter is an electrical device that adjusts the frequency of an input power source to control the speed and torque of electric motors, commonly used in industrial applications like pumps, fans, and conveyor systems.

- Power: 0.75 kW

- Input Voltage: 1 phase, 230 V, 50/60 Hz

- Rated Output Current: 4.5 A

- Output Frequency: 0 to 999.9 Hz

- Protection Rating: IP65

- Type of the equipment: Optional equipment

- Voltage: 380-400V

The oil-free four-cylinder piston compressor is the ideal solution for those who value both performance and silence.

- Equipped with two twin-piston units with separate engines

- Four air filters

- Mechanical pressure switch

- Quiet operation (at least 25% quieter than traditional compressors)

- Carrying handle and mobile wheel support

- Principle of operation: Continuous mode

- Total power, kW: 1,5

- Voltage: 220-230V

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.

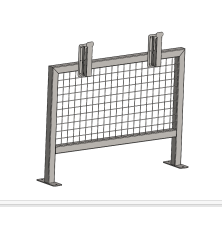

This rack is typically used as car mat holders at car washes. It can also serve as a universal stand for use in other enterprises.

- Material: Stainless steel