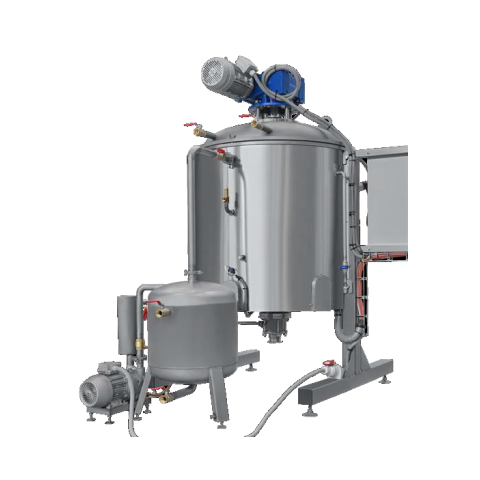

Vacuum cooker SweetStuff 200

Specialized vacuum cooking kettle for sweet masses, ideal for commercial applications and medium to large scale food production.

For a price quote, send us a request.

SweetStuff 200 is intended for low or high-temperature cooking of a wide range of goods - confectionery, jams, caramel, sauces, including high viscosity and low-liquid products.

It can concentrate various extracts and similar ingredients in the food, pharmaceutical and chemical industries.

Examples of use:┬Ā

- Jams

- Sauces

- Caramel

- Various types of confectionery assortments

- Oriental sweets

BENEFITS:

- High evaporation efficiency.

- Product cooking takes a minimum amount of time.

- The machine is compact and occupies a minimum of space.

- Ability to choose the desired temperature - Evaporation process starts at 40 ┬░C, it is possible to evaporate even at temperatures up to 115 ┬░C when caramelization of the product is required.

- Ability to work with a viscous product.

- Even mixing, heat treatment, and simple unloading.

Construction of the equipment:

- An integrated system of forced condensation.

- The mixing device is an enhanced agitator developed specifically to mix high-viscosity products that tend to stick. The stirrer is double-sided and is supplied with scrapers. It mixes the product in the cooking process and when switched to reverse rotation, it helps to unload the finished product.

- A built-in screw can be supplied for unloading the finished viscous product.

- Vacuum generation system is included.

- SweetStuff 200 is developed either with electric or steam heating.

Technical details:

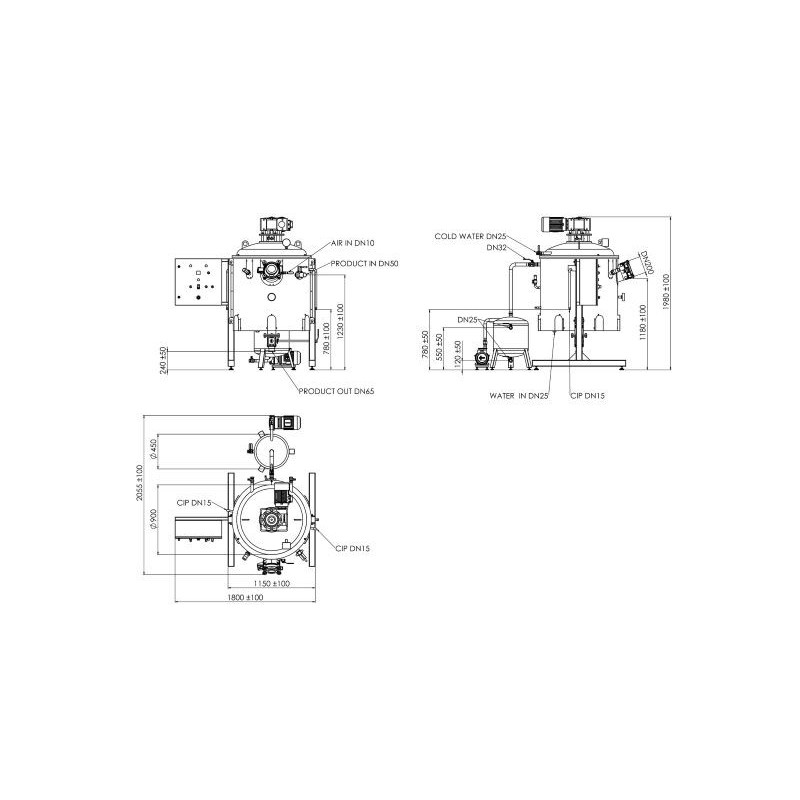

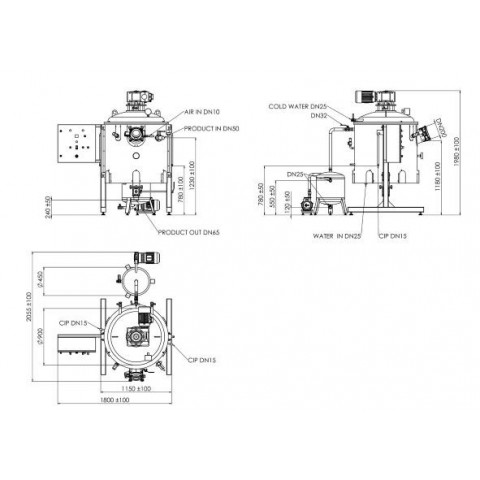

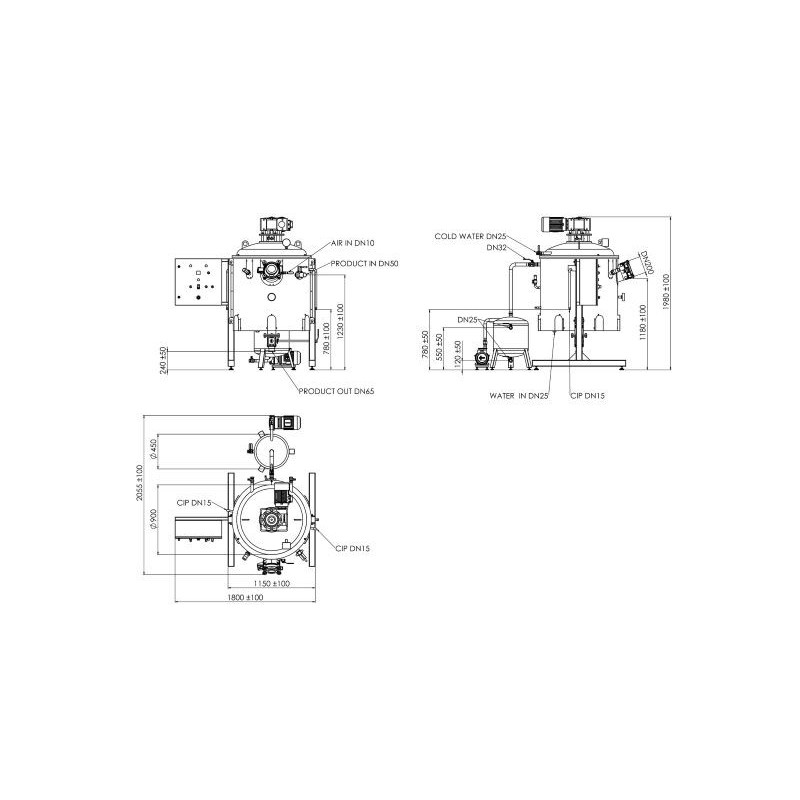

- Dimensions: 2055x1800x1980 mm

- Volume: 200 l

- Heating: electric 30 kW

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 200l

- Dimensions, mm: 2055x1800x1980

You might also like

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

Thanks to the indirect heating system, this kettle is ideal for cooking liquid dishes. It is completely made of stainless steel and equipped with a convenient drain valve.

- Material: Stainless steel

- Heating power, kW: 18

- Voltage: 380-400V

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

Tilting atmospheric cooking kettle is designed for homogeneous cooking and mixing of sauces, smoothies, jams, spreads, soups, pasta, yoghurts, ice cream, curd desserts, mousse, air confectionery masses, pastry cream, fillings for sweets, waffles, rolls, chocolate, gingerbread, cookies, muffins, rolls, pastilla, marshmallows, meringues, marshmallows, brewed dough, sponge cake.

For a price quote, send us a request.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Voltage: 380-400V

- Geometric volume: 330

- Dimensions, mm: 1700x1030x1500

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Electric cooking boilers are cooking devices powered by electricity, designed for heating and cooking products intended for consumption. They are intended for use in catering kitchens, school kitchens, professional kitchens and other food processing plants.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350l/

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

We sell many different types of cooking equipment, with a mixer or without, tilting, electric/steam/gas heating system, and many different modifications.

- Heating: Steam

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350 l