Homogenizer for Soy Milk Production MH 150/120

The price is set for the basic version of the installation for making plant milk without a steam generator

The Veggie Milk cooking kettle is used as a unit for hydrodynamic thermal extraction of substances from legumes and nuts to create a finished suspension - the basis of plant based drinks.

- Efficient and fast extraction

- Partial pasteurization due to direct steam injection

- High-powered bottom homogenizer

- Hydrodynamic mixing

- Mechanical shaft seal for the homogenizer with an open cooling system

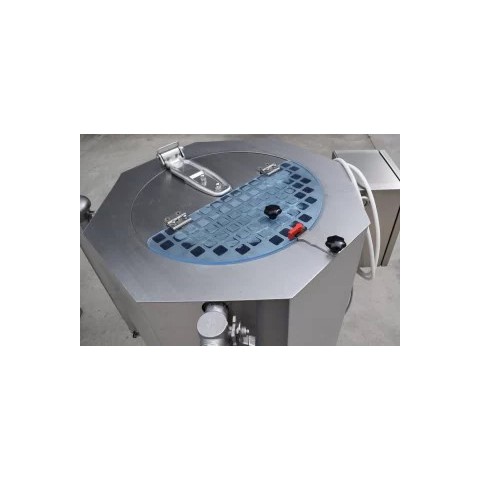

- Safety grid on the hatch cover for safe product loading

- Sectional plexiglass hatch for visual inspection

The Veggie Milk plant is used not only for industrial applications in the plant-based beverage industry, but it is also an integral part of the soybean processing process to produce tofu or other similar vegan products.

The plant milk homogenizer is suitable for the production of plant bases for beverages such as:

|

|

|

|

|

|

|

|

|

|

You can get a plant base from almost any nuts, grains or seeds.

Advantages:

- High efficiency and productivity, up to 100 liters of the base with a particle size of up to 100 microns is produced in just one cycle, the time of the cycle depends on the product, for soybeans - 5-10 minutes.

- A high degree of homogenization is achieved by the combined influence of the following factors: mechanical grinding and crushing, multi-level cutting, geometric linear speed acceleration, change in pulsating voltage, cavitation, ultrasound.

- Efficient Heating: Direct steam injection into the product is the most economical and intensive heating method with minimal inertia.

- An additional factor that increases the cost-effectiveness and efficiency of plant milk production using a plant milk homogenizer is the effect of converting the mechanical energy of the homogenizer into thermal energy, which allows for faster heating and saving on steam.

- Veggie milk has a hygienic design that is easy to clean. There are no dead zones where product can accumulate. The installation has a self-cleaning system: cleaning is carried out by circulating the cleaning agent and water throughout the homogenizer along the path of the product.

- A cooling system for the mechanical shaft seal, which protects the operation of the unit during dry running or when the volume of processed product is small.

- Thermal insulation for the working tank to reduce heat loss and ensure safe equipment operation during its use.

Processes:

|

|

|

|

|

|

* Steam generator - option

Basic version

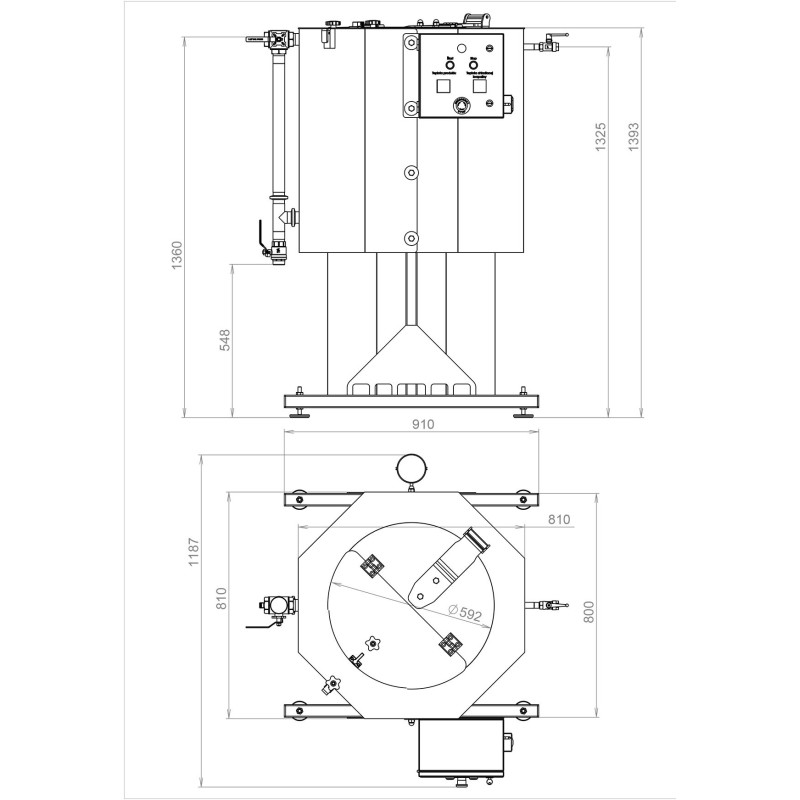

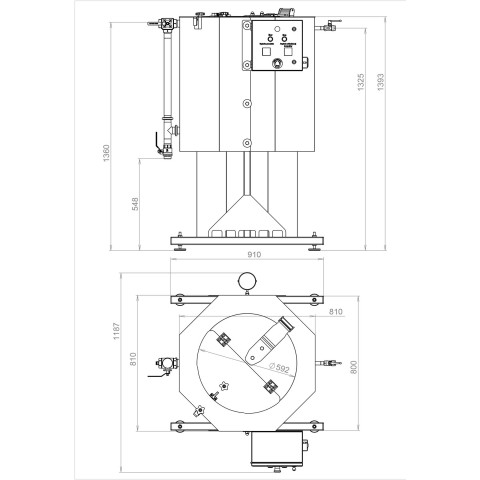

The Soy Cow or Veggie Milk unit comprises an atmospheric reactor mounted on a supporting structure and a homogenizer with a┬Ā electric drive suspended at the bottom. It includes an extended stainless steel electric motor shaft, a mechanical seal, a perforated protective housing for the external rotary units of the homogenizer, an external circulation circuit, a direct steam supply system, and a sectional opening top cover. The unit is equipped with a frequency converter and an analog thermometer for measuring product temperature.┬Ā

Operating principle

The homogenizer grinds the product in a humid environment with the external circulation circuit turned on. Purified steam is introduced into the lower part of the apparatus through a specialized bubbling system, facilitating intense heat transfer, hydrodynamic stirring, mixing, and absorption. Direct injection of purified steam into the product allows you to significantly intensify the heating process with minimal energy losses, which also partially pasteurizes the product.

Options:

- Bottom decorative stainless steel housing

- Height-adjustable legs

- Support structure on wheels with locks (brakes)

- Changing the electric motor power within the size category of 132

- Time relay

- Water meter

- Steam control system

- Control with PLC controller

- Steam generator (control and safety fittings are not included in the basic delivery package)

Additional equipment:

- Vacuum coater for water saturation and soaking beans, grains and nuts

- Feeding conveyor

- Separator/centrifuge

- Okara press

- Steam purification filter

- Pasteurizer

- Productivity: 600 kg/h for soybeans

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 120l

- Total power, kW: 7,5

- Voltage: 380-400V

You might also like

The generator is mounted on a stainless steel platform support, covered with stainless steel AISI 304 properly shaped with electrical and water connections already made. Stainless steel cocks AISI 316, malleable iron pipe fittings, feed water pump (mod. TP78A CALPEDA) with 1 stainless steel non-return valve, with VITON seal.

- Heating power, kW: 24/ 32/ 48

Supporting structure on wheels with locks (brakes), 2 swivel wheels, 2 swivel wheels with a brake.

- Type of the equipment: Optional equipment

Set of 4 height adjustable legs+/- 100 mm.

- Material: Stainless steel

- Type of the equipment: Optional equipment

Inline Yumix Basic homogenizers have the lowest price in the range of YUMIX homogenizers and models range from 1.1 to 3 kW.

- Material: Stainless steel

- Engine power, kW: 1,1/ 1,5 / 2,2/ 3

- Principle of operation: Continuous mode

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

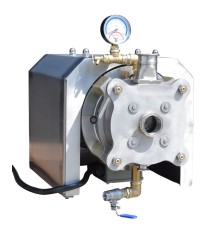

The circulation type homogenizer is designed for emulsifying thick fluids and other viscous materials within the food, chemical and cosmetic industries. Its working principle is based on the rotor/stator principle.┬Ā

- Material: Stainless steel

- Engine power, kW: 1,1/ 7,5 kW

- Country of origin: Slovakia

The homogenization of butter is carried out in order to improve the butter's consistency and taste stability under storage conditions.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We produce atmospheric honey homogenizers with a batch load ranging from 7500 up to 22 000 kg of honey. The homogenizers HPL are designed for thoroughly mixing, blending, and homogenizing various kinds of honey to improve its qualities.

The price depends on the options you choose.

- Productivity: do 12000 kg

- Material: Stainless steel

- Volume: 8000 l

A professional mixer for the production of mayonnaise, sauces, soups and other homogenized products. The price depends on your production capacity, as well as the technological requirements.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 200l

- Total power, kW: 6

Model VMG S is an effective and reliable vacuum homogenizing unit designed to produce a wide range of liquid, pastry and viscous products with different requirements for the production conditions.

The price is indicated for the basic version of the vacuum reactor without additional options, the final cost depends on the modifications

The vacuum homogenizer is an ideal solution for the production of food, for example mayonnaise, it is also suitable for the cosmetics industry - the production of toothpaste. This model of the homogenizer is based on a vacuum reactor with an external homogenizer and an external circulation circuit, the parameters of which are selected as options.

- Tilted design - 25% more efficient mixing

- Easily disassembled reinforced frame mixer, for thick and viscous products

- Jacket for the coolant around the bottom and walls of the working reactor

- The vacuum reactor can withstand a vacuum up to -0.8 Bar

- A large number of options to choose from to suit various requirements

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l/ 650l

- Total power, kW: 0,55

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The inline homogenizer is designed for mixing, emulsifying, dispersing, and homogenizing thick and viscous products in the production of mayonnaise, soy milk, toothpaste, yogurt, and much more. It can be installed in an external circulation circuit of reactors, production lines, or used independently with a loading hopper for processing small volumes of products.

- Creates stable emulsions and suspensions

- Reduces particle size

- Quickly dissolves solids

- Accelerates chemical reactions

- Does not require an additional pump

- Material: Stainless steel

- Engine power, kW: 5,5/ 7,5/ 9/ 11/ 15

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The butter texturizer FBHG is intended for mechanical processing of frozen blocks of butter, animal fat, margarine and other plan fats, without prior defrosting.

- Material: Stainless steel

- Principle of operation: Continuous mode

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

- Built-in jacket for the bottom and walls of the unit.

- Cutter knives with a powerful electric drive

- Slanted design for efficient mixing and chopping

- Forced circulation circuit (optional)

- Wide range of options

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The price depends on the required capacity.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350 l

- Total power, kW: 1,5

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar