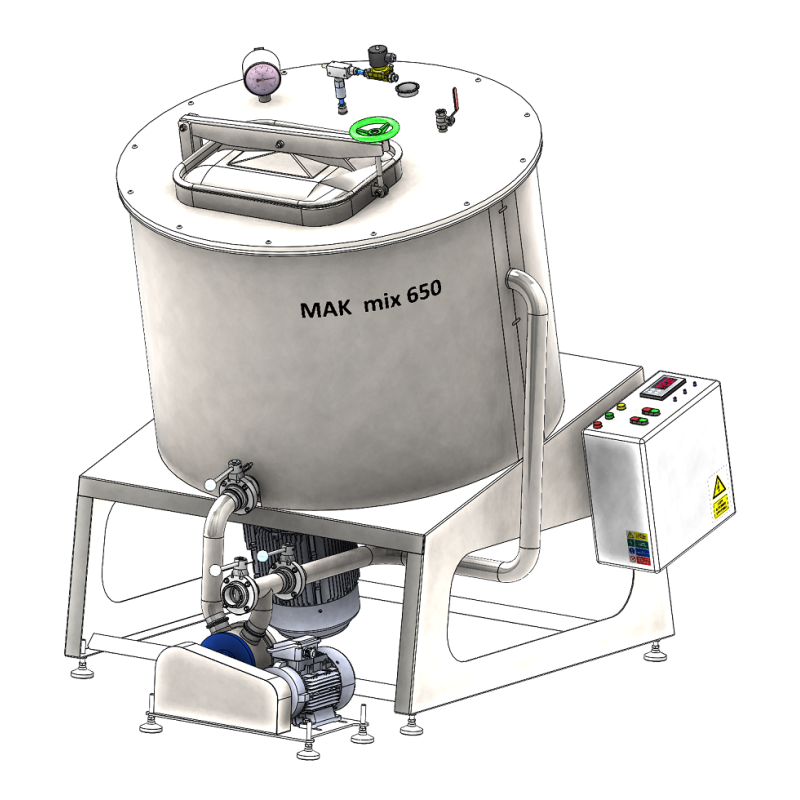

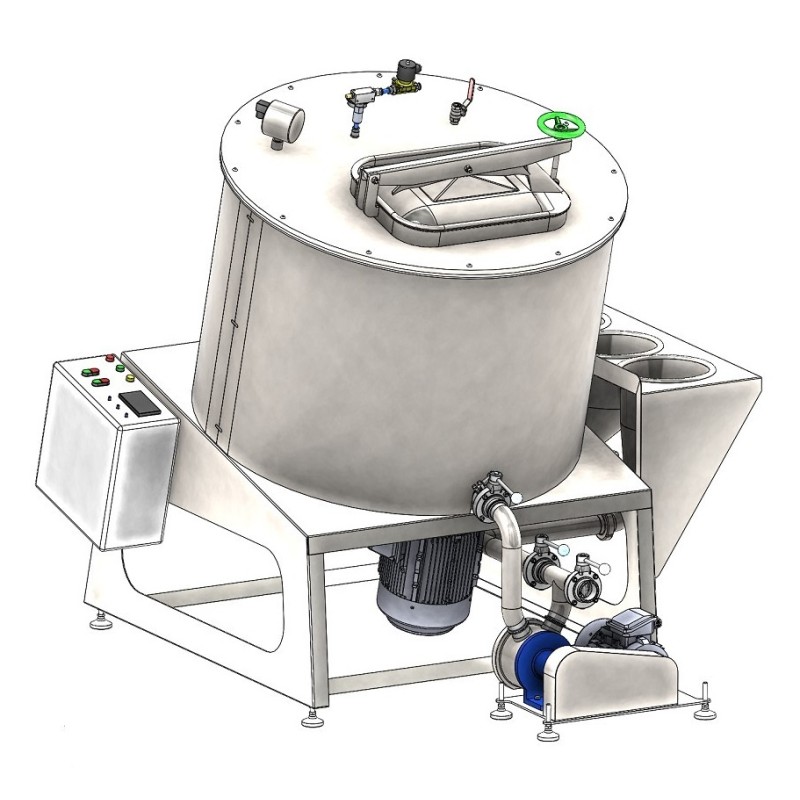

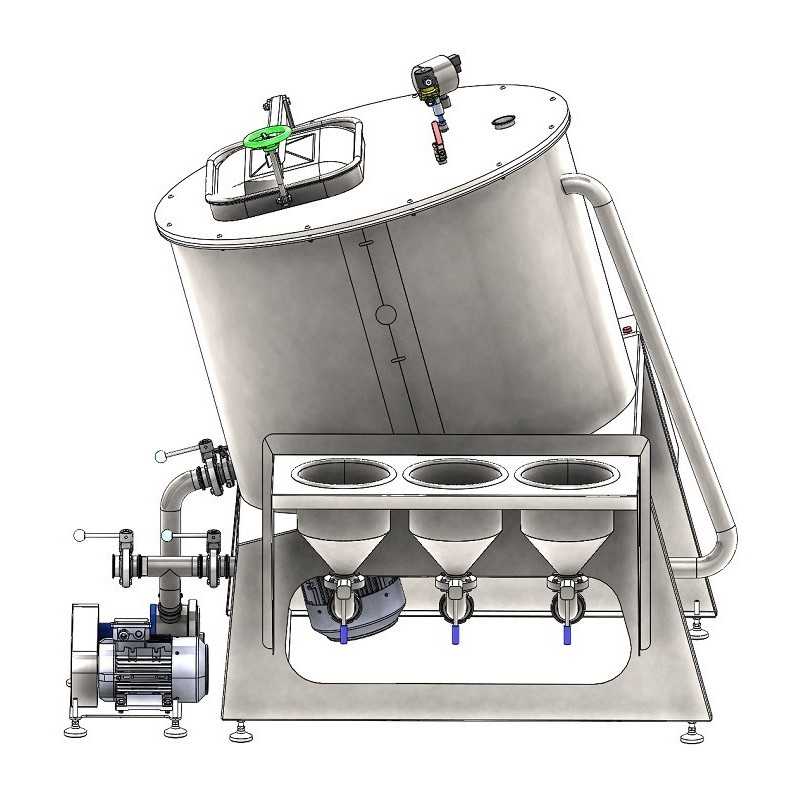

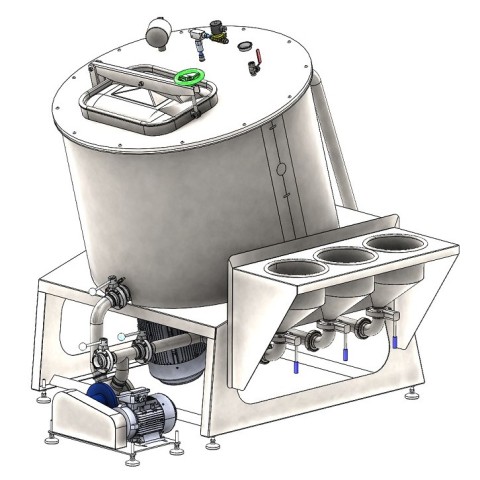

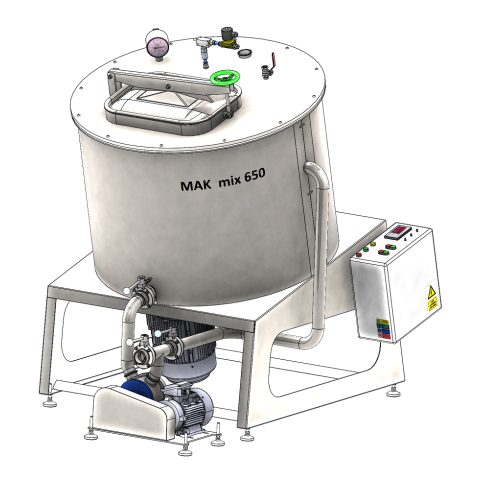

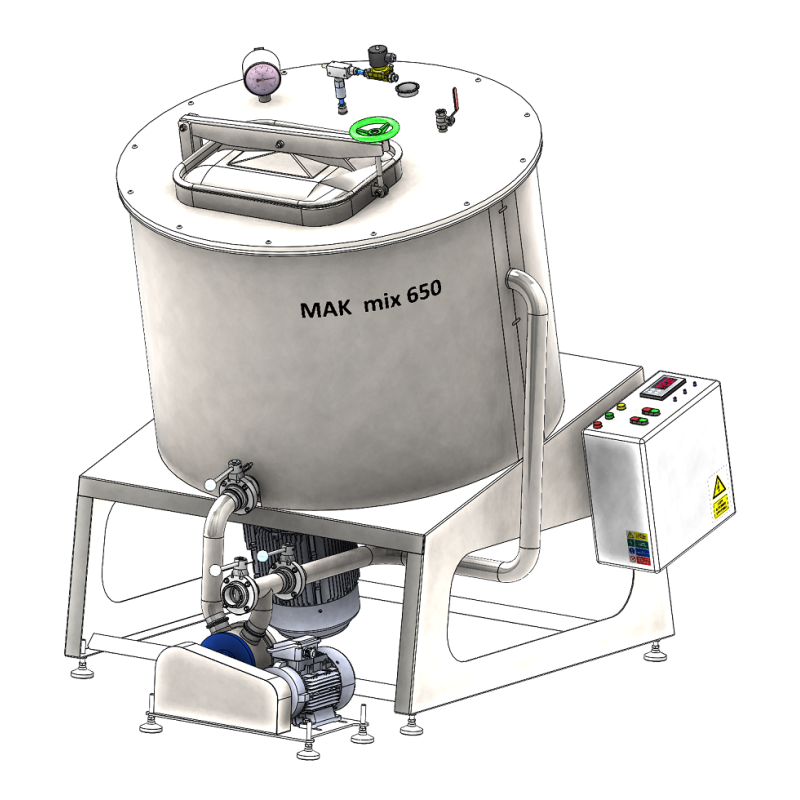

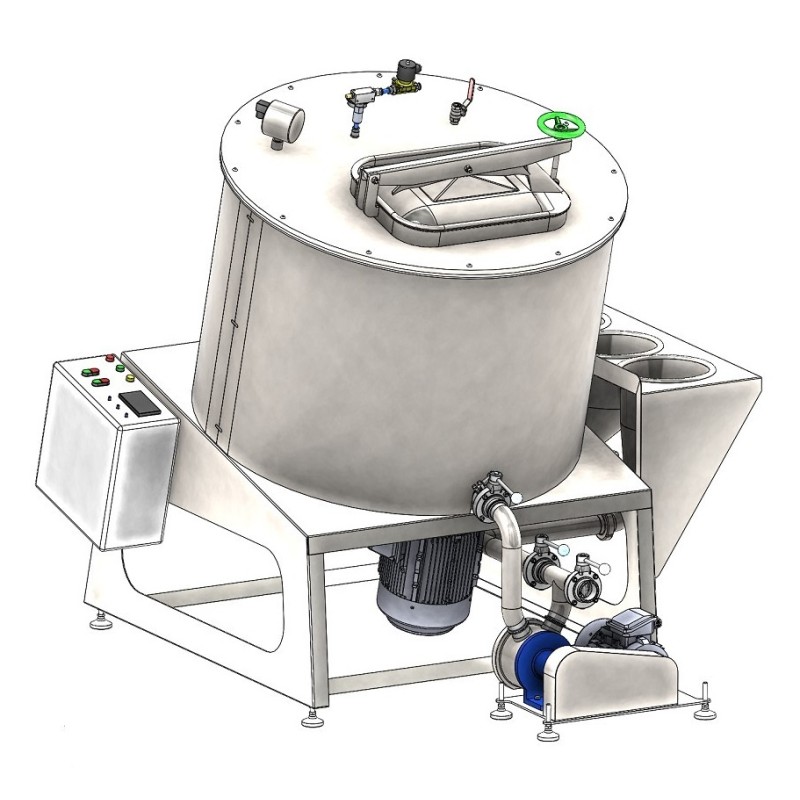

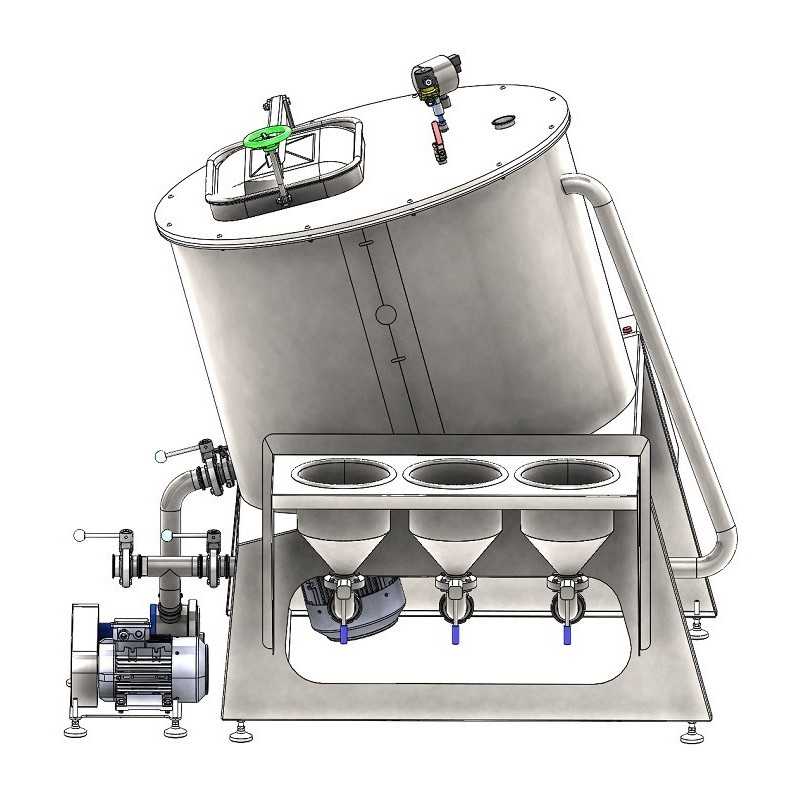

Vacuum mixer MakVacMix 350-650

Multifunctional vacuum mixer/homogenizer for grinding, mixing, and homogenizing products to obtain homogeneous masses.

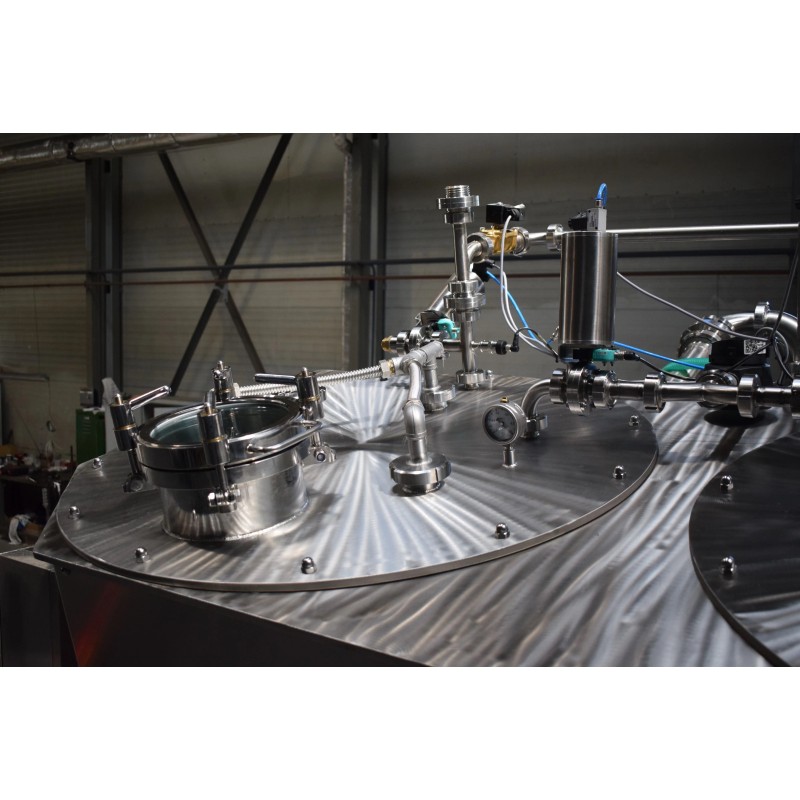

- Built-in jacket for the bottom and walls of the unit.

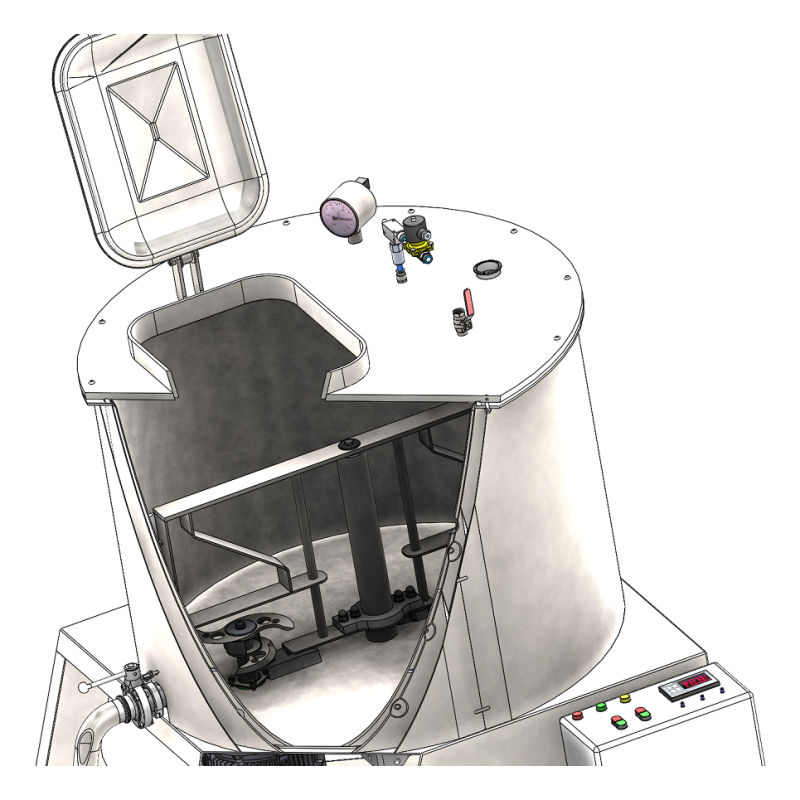

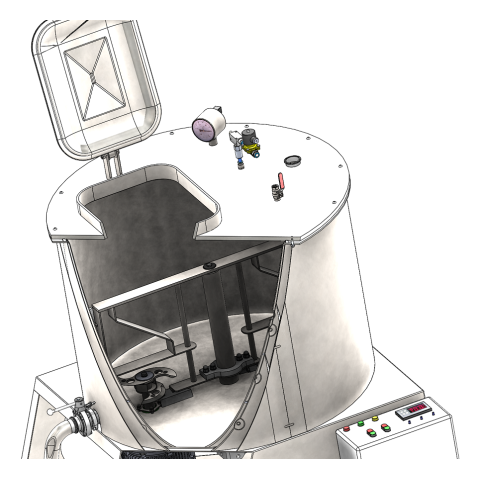

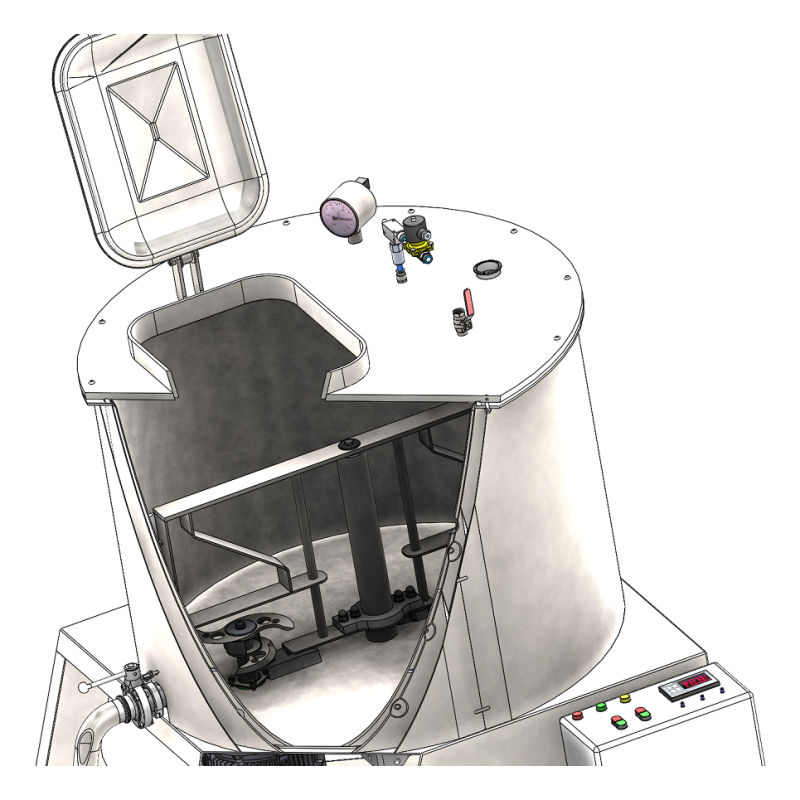

- Cutter knives with a powerful electric drive

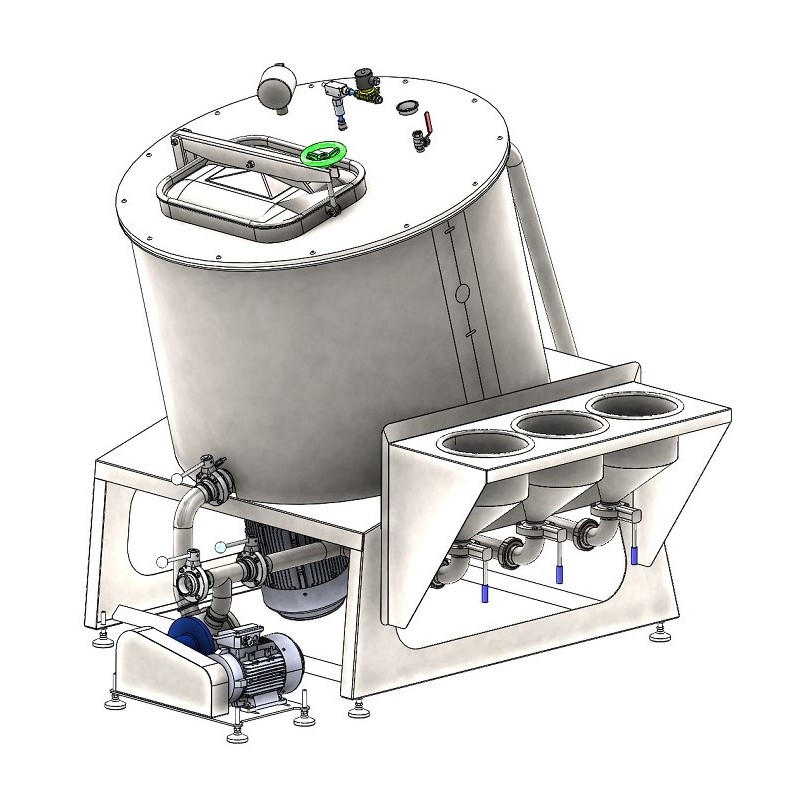

- Slanted design for efficient mixing and chopping

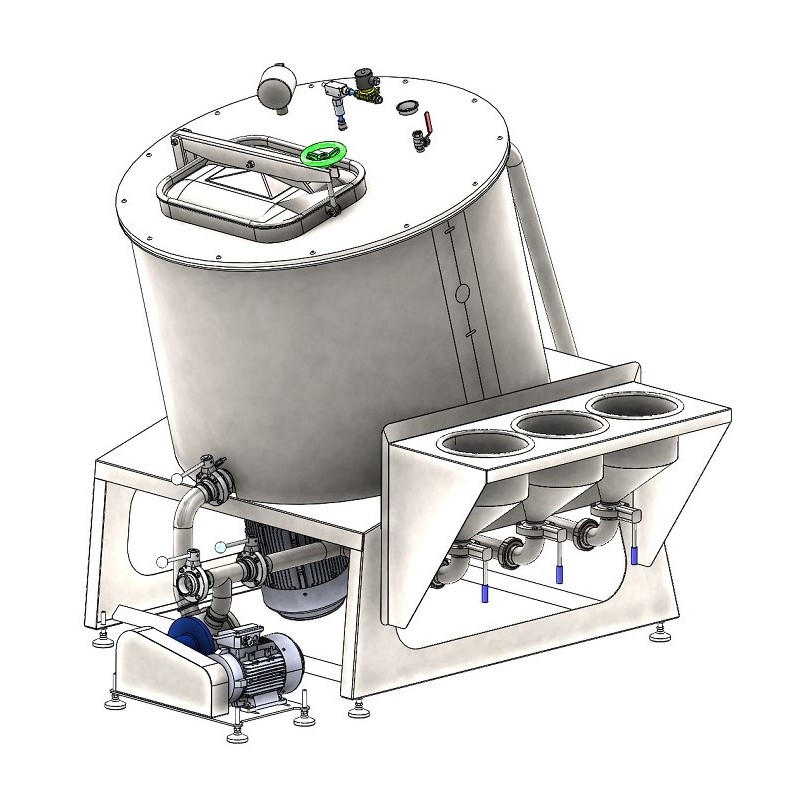

- Forced circulation circuit (optional)

- Wide range of options

A unique feature of the system is the ability to replace the cutter knives installed in the lower part of the inclined reactor with a bottom homogenizer of the Ultra Shear type, enabling the creation of stable emulsions on a water-fat base.

A multifunctional vacuum mixer is often utilized for grinding, mixing and homogenizing, to obtain homogeneous masses of various products, it can be used for products such as:

|

|

|

|

|

|

|

|

Advantages:

- The vacuum reactor allows for thermal processing under vacuum conditions, which is important for the production of heat-sensitive products that lose their nutritional value at higher temperatures.

- Depending on the vacuum source which is available as an option, it is also possible to vacuum cool or vacuum the product to reduce pathogens in air bubbles created when chopping or beating the product.

- The vacuum also serves to maintain the sterility of processing procedures, reducing the potential for contamination. This is highly important both in the production of food items and in the manufacturing of toothpaste, gels, and creams.

- Mixing is 20% more efficient thanks to the inclined design of the structure. The cutter knives are installed at the lowest hydraulic point, ensuring high-quality product grinding. The mixing device and cutter knives facilitate "internal" circulation of the product, thereby achieving high product homogeneity.

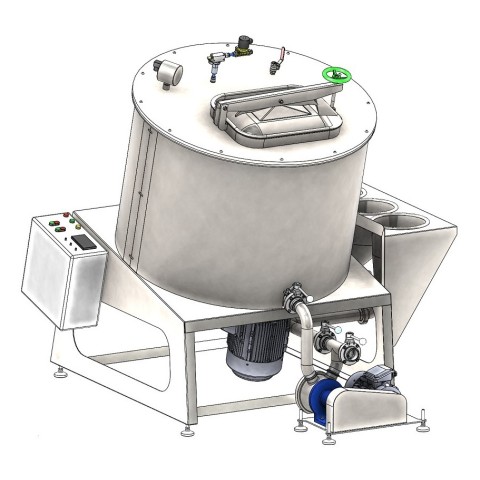

- The mixer can be retrofitted with an external forced circulation circuit to increase the intensity of heat transfer, the pump of which also facilitates quick and convenient unloading of the product from the installation.

Processes:

|

|

|

|

|

|

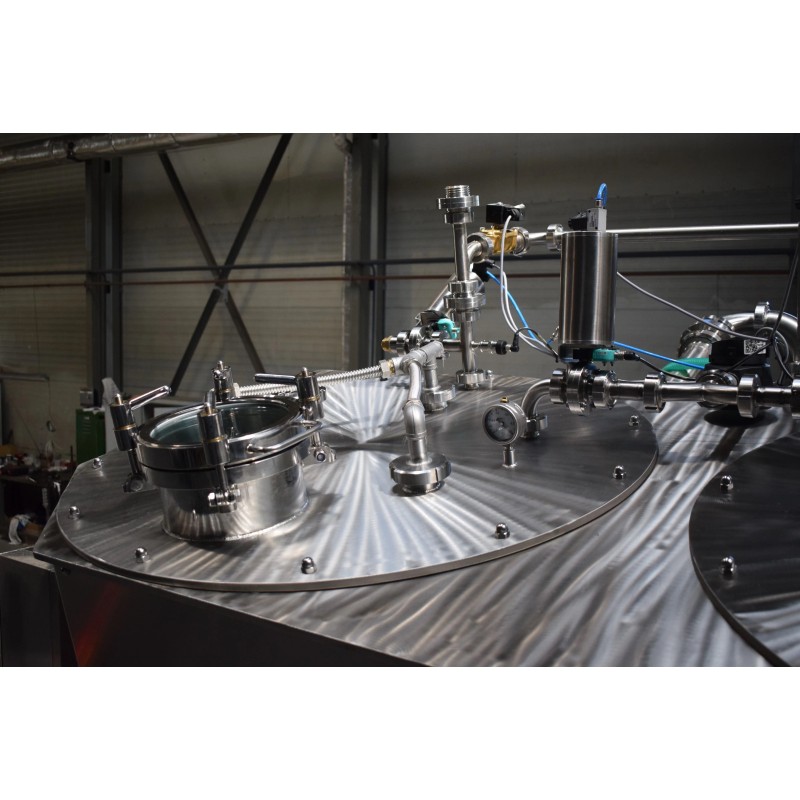

Basic version

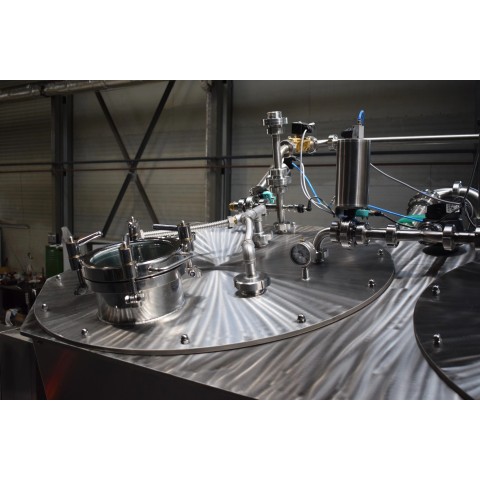

The basic version comprises an inclined vacuum reactor with a jacket for the coolant (heating or cooling medium supplied from an external source). In the initial version, it is equipped with cutter knives and a mixing device. As a vacuum source, the basic version uses an ejector powered by compressed air from an external source (the compressor is not included in the delivery). Product loading can be done through the top hatch of the unit or, optionally, using a pump through the outlet valve. The maximum vacuum depth is 0.8 Bar. In the basic version, the vacuum is not adjustable; as an option, a vacuum gauge can be installed to monitor and maintain the specified vacuum depth. The basic control version includes a thermal controller with a temperature sensor in the product and a controlled coolant supply valve. Frequency converters for cutter knives and the mixing device allow for the adjustment of the operating speed.

The coolant (water, steam) can be supplied into the installation's jacket. For certain coolants, the pressure at the entrance to the jacket can reach a maximum of 0.5 Bar; it is advisable to install a pressure reducer.

Options:

- Vacuum oil pump - recommended for creating a deep vacuum and vacuum cooling (to use the vacuum cooling function, it is recommended to select an additional option - a system for removing and condensing secondary steam).

- Water ring vacuum pump - recommended for quickly creating a vacuum, it requires a cold water supply (cold water connection) to operate.

- External forced circulation circuit with a self-priming pump for convenient and quick product unloading.

- Ultra Shear homogenizer - a kit for replacing cutter knives.

- Maintaining and adjusting the vacuum.

- A System for the removal and condensation of secondary steam.

- Sources of coolants (hot water supply, ice water stations).

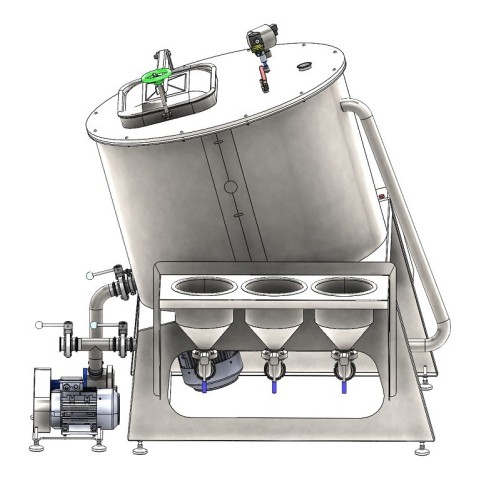

- A system of cones with pipelines as well as control and shut-off valves.

- Automatic component dosing system based on a touch screen controller.

- Vacuum loading through a specialized pipe with a hose for vacuum filling of the container through the bottom valve to the level of the working fluid.

- Quiet compressor for compressed air at 6-10 Bar.

- CIP heads (nozzles) for washing are made out of food-grade stainless steel; as an additional option, rotary nozzles can be ordered to cover all surfaces of the container, including the opening hatch of the equipment.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 350l/ 650l

- Total power, kW: 13/ 17

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

You might also like

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Vacuum mixer processing plant for viscous products is an ideal solution for the production of pilot batches and the industrial manufacturing of a wide range of products from small to medium capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

The vacuum homogenizer with an inclined design is designed for processing and manufacturing a wide range of liquid, pasty and viscous products with different requirements for their production conditions and other products including those with a high viscosity.

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Principle of operation: Batch mode

- Country of origin: Slovakia

A twin-screw mixer with a homogenizer is an ideal solution for the production of creamy cheese, such as feta cheese, including with various flavors and seasonings. Thanks to mechanical homogenization, the cheese acquires a delicate structure without changing the individual taste properties of the product. It is used for plasticizing, creaming and softening butter, margarine and other fats.

- Capacity of the receiving hopper 50L

- Compact tabletop design for convenient operator maintenance

- A powerful independent drive for each screw with a reverser

- Easy maintenance and cleaning of the equipment

- Productivity: 250 kg/h/ 1500 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Total power, kW: 3,5

- Voltage: 380-400V

The conical bottom mixer with a 400-liter capacity is designed for efficient mixing and smooth product discharge. Its conical shape directs contents toward the lower outlet, making it ideal for processing thicker or denser materials in an atmospheric-pressure environment.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 400l

- Voltage: 380-400V

Homogenizer for the production of whipped cream, ice cream, and much more. It allows you to obtain stable liquid emulsions of food mixtures.

- The homogenizer can be installed directly into the container with the product

- High productivity - in just 8 minutes, it is possible to whip up to 60 liters of milk mixture

- The peripheral speed of the knives is 16 m/s

- Material: Stainless steel

- Engine power, kW: 0,37/ 2,2

- Country of origin: EU

- Voltage: 380-400V

Suitable for mixing a small amount of dough or meat as well as other thick mixtures.

- Material: Stainless steel

- Engine power, kW: 0,55

- Principle of operation: Batch mode

- Volume: 10l/ 20l

We offer wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments. Price depends on the chosen option.

- Heating: Gas Steam

- Productivity: 300 l 600 l 1000 l

- Operation mode: Automatic

- Type of the equipment: Individual machine

The NORMIT drum mixers are designed for thorough mixing for products such as combined feed for animals, infant formulas, baby food, food concentrates and additives, sports supplements and nutrients, coffee, tea, pharmaceuticals and chemical products.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l/ 200l/ 500l

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l

The twinscrew mixer with two horizontal shafts is designed for intensive mixing and kneading dough as well as chocolate, pralines and other similar products with medium or high viscosity.

- Material: Stainless steel

- Engine power, kW: 2,2

- Country of origin: Slovakia

- Weight: 281 kg

- Volume: 500l

This is a 400 l capacity heating boiler, we offer different capacity commercial cooking boilers.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 25

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 400l

- Voltage: 380-400V

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

These meat tumblers are designed for removing air and drawing moisture and marinade into the meat under the conditions of a vacuum.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 600l/ 900/ 1200l/ 2000 3000

The Y-shaped food mixer contains a double vessel with a 90┬░ apex angle. This mixing system is designed for mixing, pre-mixing liquid, viscous, dry and bulk components to obtain homogeneous mixtures.

- Special shape designed for fragile products that may break when exposed to centrifugal force

- Effective mixing of products with different components to obtain a homogeneous structure quickly and with minimal energy consumption

- Gentle mixing and tumbling due to complex random trajectories of product movement

- Compact installation

- Easy maintenance and high level of safety - safety bar with a position sensor

- Material: Stainless steel

- Engine power, kW: 0,75

- Volume: 150l

Butter churner with a volume of 50 L and a usable volume of 25 L for the traditional production of butter from cream.

- Material: Stainless steel

- Engine power, kW: 0,55

- Geometric volume: 50 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600