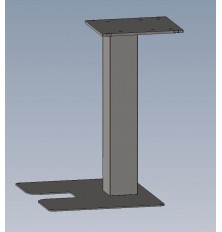

Working table for the fryer - additional module

The working surface is made out of food-grade stainless steel, on top of which the deep fryer can be installed. It is quipped with wheels for ease of movement.

An additional working table for the compact universal fryer 400/1100/12

Purchasing this add-on module allows you to use the additional options for the modular fryer, such as an additional 75 liter oil tank as well as, if it's necessary to supplement the fryer with an automatic circulation system - a "waterfall" of hot oil. The installation of both of these modules is possible only if there is a table module present.

Table dimensions 1462*605*1005 mm

- Material: Stainless steel

You might also like

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The combination of the compact 400/1100/12 fryer with the secondary upper pressure conveyor, allows you to expand the variety of products that can be fried on it. It ensures uniform, high-quality frying of fresh and semi-finished products in small to medium scale, making it suitable for small-scale production, professional kitchens and street food businesses. The fryer fully submerges the product in oil throughout the whole frying process with the help of the second pressure conveyor that forces the product beneath the oil's surface.

- The maximum height of the fried product is - up to 50 mm

- Immersion thermometer for visual monitoring of the oil temperature

- Frying time can be set from a few seconds up to an hour!

- High temperature ŌĆō up to 200┬░C

- The conveyor belt is made out of a food-grade stainless steel thin mesh

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The price is set for the combination of a basic fryer model and an additional module with rotating paddles.

The universal modular SnackPro fryer equipped with an additional paddle module is designed for frying thin slices of products that require immersion beneath the oil level.

- Adjustable frying time from a few seconds up to an hour

- Compact, tabletop version

- The paddle conveyor is installed on top of the basic fryer

- Safety thermostats on each heating element

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Total power, kW: 12

- Oil volume: 60l

- Voltage: 380-400V

The modular cooling conveyor is produced as a standard tabletop version with a section length of 1000 mm; in addition to it, you can order a stainless table or a frame supporting structure. The air cooling conveyor can be sectionally increased in length by the required number of sections.

- Compact, easy to install on any work surface

- Features a fine-grained stainless steel mesh for high temperatures and small-sized products

- Easily combined in line with a tabletop fryer 400/1100/12

- Easy maintenance and cleaning

- Material: Stainless steel

- Principle of operation: Continuous mode

- Working Area Width: 400 mm

Rechargeable and portable, ideal for measuring sugar content in fruit juices and beverages, ergonomic design.

Additional option to VMG laboratory vacuum homogenizer 20/50.

- Type of the equipment: Optional equipment

Designed for a load of up to 200 kg!

The 5 kW induction cooker is the best alternative to traditional electric and gas stoves. It reduces energy costs, improves safety, and minimizes air pollution, making it suitable for both stationary kitchens and mobile catering setups. Its compact design also makes it a practical choice for small kitchens where space and efficiency matter.

- 10-step power (500ŌĆō5000 W) or 10-step temperature (60ŌĆō280 ┬░C) control

- Connection - 230 Volt

- Compact dimensions: 410x500x200 mm

- Temperature range from 60 to 280 degrees

- Heating power, kW: 5

- Voltage: 220-230V

Industrial refractometers are used to measure the concentration level of liquids in a continuous flow across various industries, applications, and industrial setups. They provide real-time measurement data, ensuring precise process control and maintaining the desired concentration of liquids. This enables industrial automation by eliminating the need for manual sampling and adjustments, allowing for consistent and accurate production.

- Type of the equipment: Optional equipment

The AISI 304 stainless steel oil drain system is suitable for use with most deep fryers. It allows you to filter the oil directly when draining it from the fryer.

- Material: Stainless steel

- Weight: 13,5

Compact and powerful gas stove with 3 rings designed for the connection to standard LPG cylinders. Ideal for heating large volumes of liquid, cooking soups or sauces in cooking kettles, and maintaining meal temperatures during preparation or service. The sturdy, open-frame design ensures excellent stability and high load capacity for everyday use in catering and food processing.

The sturdy mobile base for large pots, with a diameter ranging from 405 mm to 625 mm, is designed to support and easily transport our 50L, 100L and 150L cooking kettles.

- Made out of stainless steel

- Features casters with brakes on each wheel for secure handling

- Universal model for pots with diameters from 405 to 625 mm

- High load capacity - up to 200 kg

- Material: Stainless steel

- Type of the equipment: Optional equipment

Contact pressure gauge with a Bourdon tube, and a bottom connection.

- Type of the equipment: Optional equipment

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

- Type of the equipment: Optional equipment

Steel balls for grinding chocolate are essential components used in ball/bead mills. These 6 mm diameter balls are made out of hardened steel and are considered as consumables required for operating the BALL MILL 5.

- Spherical shape with a diameter of 6 mm

- High hardness steel

- Supplied in 10 kg boxes

- The mill requires 2 boxes (20 kg in total).

- Type of the equipment: Spare parts

The set consists of 20 shelves from AISI304 stainless steel.┬ĀAdditional option for MAK DRYER 7-14.

- Material: Stainless steel

- Type of the equipment: Optional equipment

A set of additional paddles for transporting and unloading the product from the working area of ŌĆŗŌĆŗthe universal 400/1100/12 fryer.

Thermal insulation of the drying cabinet body to reduce heat loss during product drying. Additional option for the MAK DRYER 7-14.

- Type of the equipment: Optional equipment

In the production of condensed milk, a refractometer is used to accurately determine the solids content of the product, which is essential for meeting production standards and ensuring compliance with legal regulations.

- Type of the equipment: Optional equipment

Various installation types are possible: in-line, directly into the product tank or via a bypass connector.

- Type of the equipment: Optional equipment

Stainless steel mesh baskets designed for use with our cooking kettles, blanchers, evaporators, fryers and pasteurizers. Ideal for thermal processing, subsequent draining, and unloading of products such as vegetables, fruits, pasta, meat, or jars after cooking, blanching, or pasteurization.

Available in multiple sizes ranging from 30├Ś30 to 40├Ś40 cm.