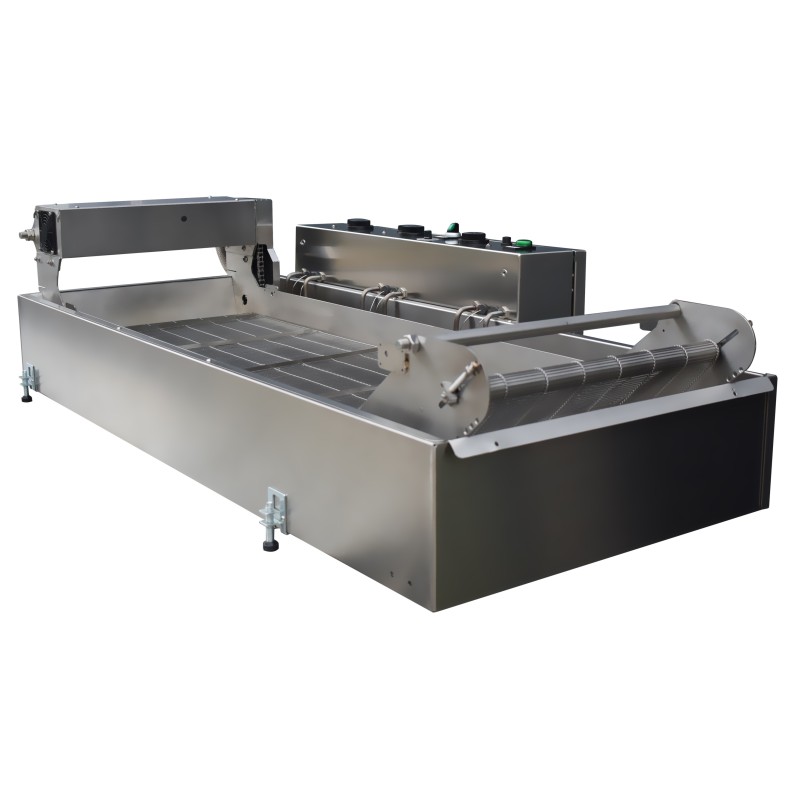

Continuous conveyor fryer 400/1100/12

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules â the double conveyor fryer and the paddle conveyor fryer â we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

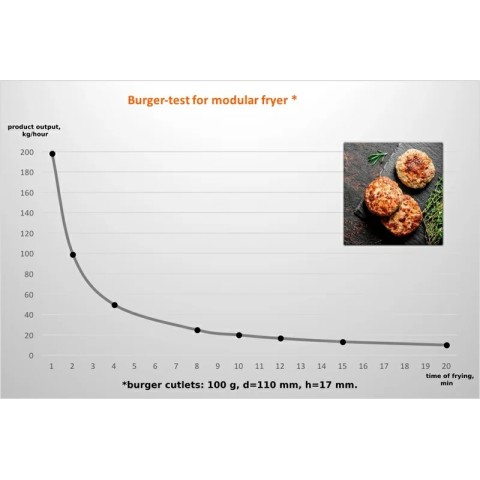

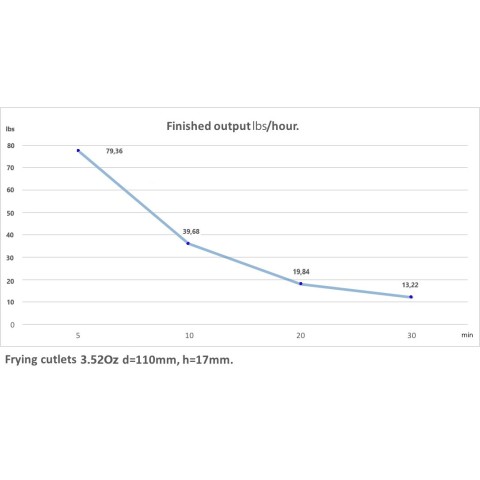

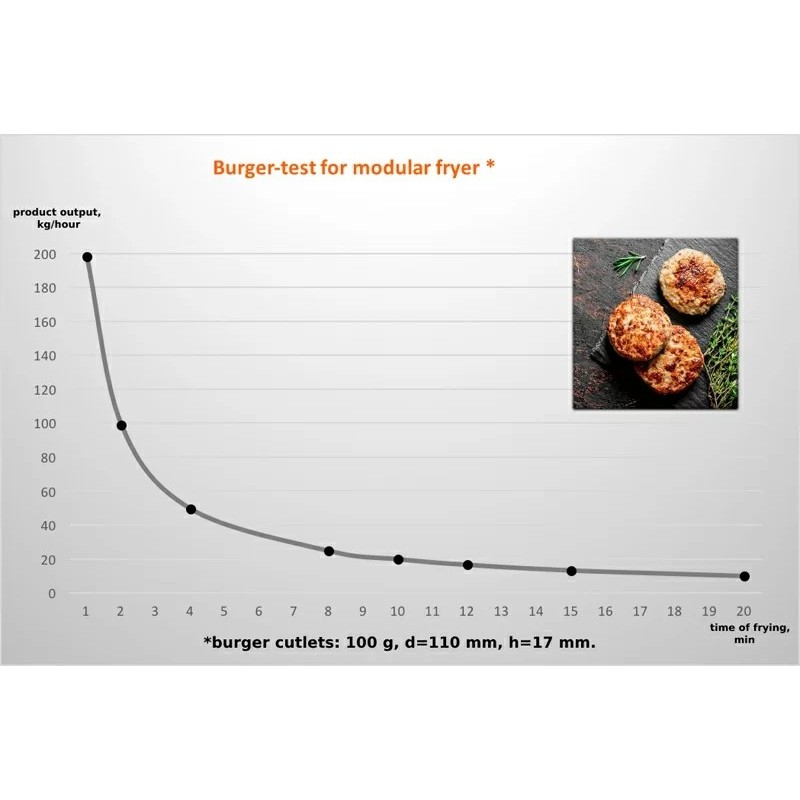

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

A versatile tabletop modular fryer suitable for HoReCa, street food enterprises, catering companies, and other food service businesses in the catering sector. It can also find an application in larger food production enterprises for laboratory purposes or for the production and processing of small batches of fried products.

The continuous fryer allows you to fry a wide range of food products with low air and moisture content, such as:

|

|

|

|

|

|

|

|

|

|

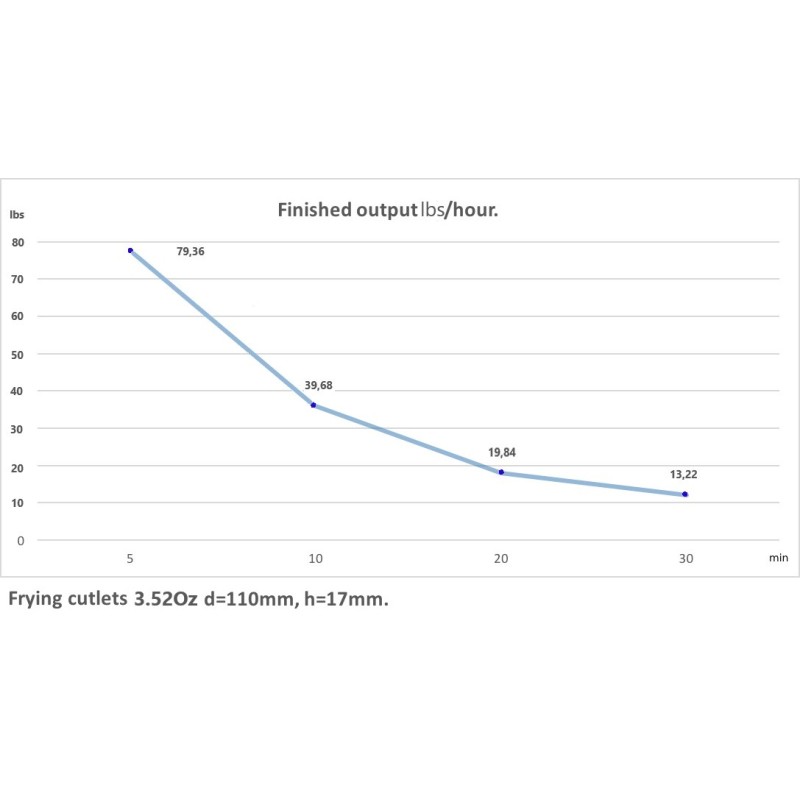

With a set roasting time of 2 minutes and a product layer thickness of 20 to 40 mm, it is possible to roast up to 20â26 kg of nuts per hour. The test was conducted using cashew nuts.

Advantages:

- Stainless steel heating elements with direct powerful heating

- Fast and highly efficient heating, ensuring reduced oil carbonation in the heating sections!

- Possibility of individual thermoregulation of each heating section!

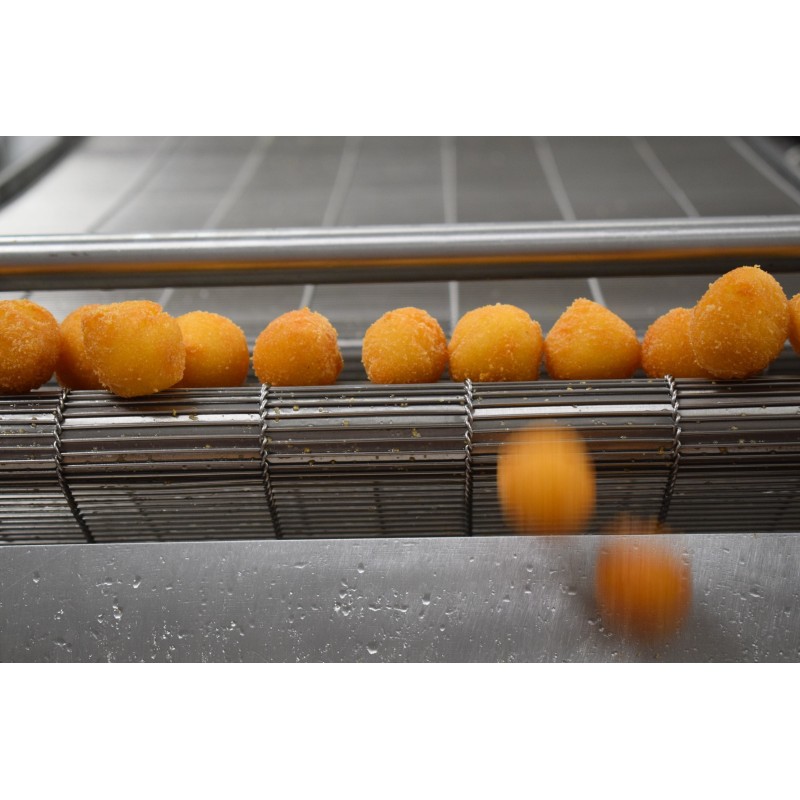

- Fine conveyor mesh made of food grade stainless steel â cell size 7x56mm.

- Safety thermostats on each heating element

- Simple and convenient maintenance

- Compact installation with the possibility of installing on work tables/surfaces* in professional kitchens** (* - with a maximum surface length of up to 1000 mm for convenient unloading of oil, ** - as part of additional equipment we offer work tables with additional built-in systems)

- Thermal insulation of the working bath to reduce heat loss and for safe operation or maintenance

- Guaranteed 100% oil discharge, outlet needle valve located at the lowest hydraulic point

- The controls are located directly on the fryer body

- The presence of a special âcold zoneâ for separated pieces of product, which, when dropped into, burn less and the process of oil spoilage slows down

- Immersion thermometer for monitoring the current oil temperature

- Maximum heating temperature - up to 200 degrees C*** (*** - depending on the type of oil)

- Small oil volume due to the reduced working bath depth, significant oil savings even with an immersion fryer module

- Work surface for pre-laying out the product

- Loading tray with a perforation section to get rid of excess breading/batter before loading into the fryer, this allows you to reduce carbonation of the oil and extend its service life

- Modular frying system with many additional equipment options for various products and additional accessories

- It provides a large working area for frying even with its compact size

Basic version

The compact tabletop fryer is intended for the continuous frying of processed food products. Its functions and capabilities are comparable to large industrial conveyor machines, and thanks to the additional modules, it opens up an opportunity of business diversification for smaller businesses!

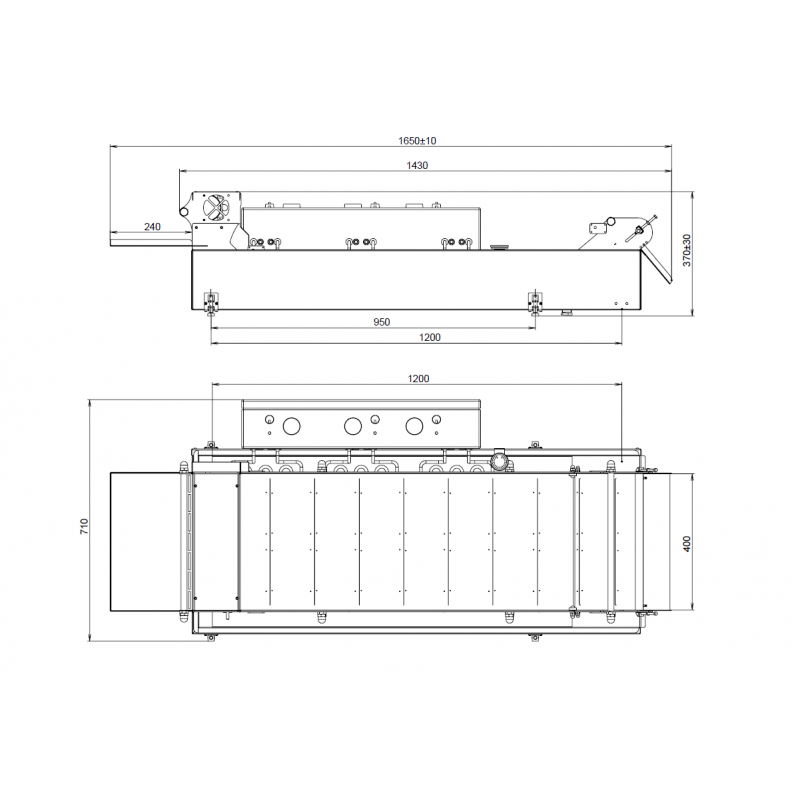

The basic version consists of a working bath made out of food-grade stainless steel, a body with thermal insulation and an external decorative casing made out of polished stainless steel, with a conveyor installed inside that features a fine-mesh steel sheet suitable for food industry use. The installation is equipped with a heating system with individual thermostats for each heating element and a system for smooth control of the conveyor speed with a wide range of settings; from a few seconds up to an hour. The control system is installed directly on the body of the working bath for convenient and quick adjustment of operating parameters. The electric control panel with heating elements can be easily dismantled for quick and easy cleaning of the unit, due to the system of brackets and connectors.

Below the heating working area there is a âcold zoneâ. Particles of the product, dry or wet breading, entering the frying zone, pass through the fine mesh directly into the âcold zoneâ, below the level of the heating elements. In the cold zone, the frying process stops, which slows down the process of oil deterioration, its carbonization and increases the service life. The walls of the case are equipped with 15 mm thermal insulation with a heat-reflecting effect.

The fryer is equipped with a needle valve located at the lowest hydraulic point of the working area, which allows you to smoothly regulate the flow of drained oil and completely empty the working bath of oil after work. In the entrance area there is a loading tray with perforations to remove excess breading and small particles separated from the product. The deep fryer can be additionally equipped with external blades for better unloading of the product from the working area after frying.

Operating principle

The product is loaded onto the working fryer conveyor; being stationary on the grid, it is immersed below the surface level of oil, moving along at a given speed and subsequently taken out for further processing, which guarantees uniform frying of the product without damage, with the same quality and degree of frying for each batch.

When using the basic configuration with a stainless steel conveyor, it is possible to fry nuts and other similar products with a low water content, which do not float to the surface during the frying process. The basic model is often used in professional hotel kitchens for continuous deep-frying of large volumes of various semi-finished products. Including in small food processing plants, for example in nut butter production processes.

To expand the range of products, we recommend purchasing additional modules that will allow you to easily switch from frying one type of product to another.

Options:

- Additional filtration cloth

- Oil quality sensor

- Compact extinguishing system

- Secondary steam extraction system with island type filtration

- Cover without insulation/with thermal insulation

Additional modules:

- The second upper (pressure) conveyor is used for frying products with a high water or air content, which will force such products below the oil surface for even frying.

- Conveyor with windmill shaped paddles - for frying light and thin products such as chips that are suspended on the surface of the oil during frying. Specifically curved paddles gently force food slices under the oil level and move them along the fryer's working area, allowing them to be completely and evenly fried.

- Stainless steel work table for the fryer.

- Oil storage tank with a capacity of 75 liters, built into the table structure.

- Hot oil filter (with a circulation pump for oil up to 60°C as an additional option). This module also allows for blanching the product at the inlet using a âwaterfallâ of hot oil. This option is only available when ordering a work table and an additional oil reservoir.

Optional equipment:

- Loading (unloading) conveyor

- Air knife cooling conveyor for removing excess oil

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

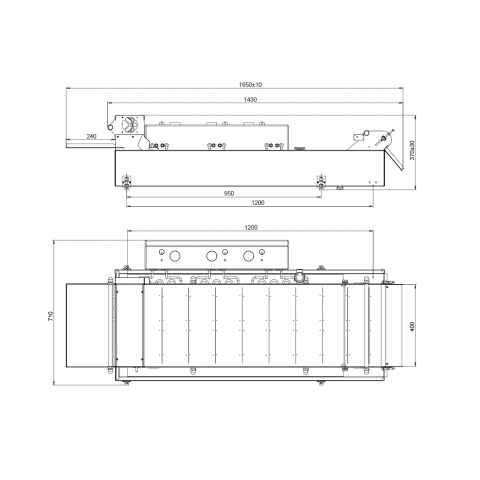

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V