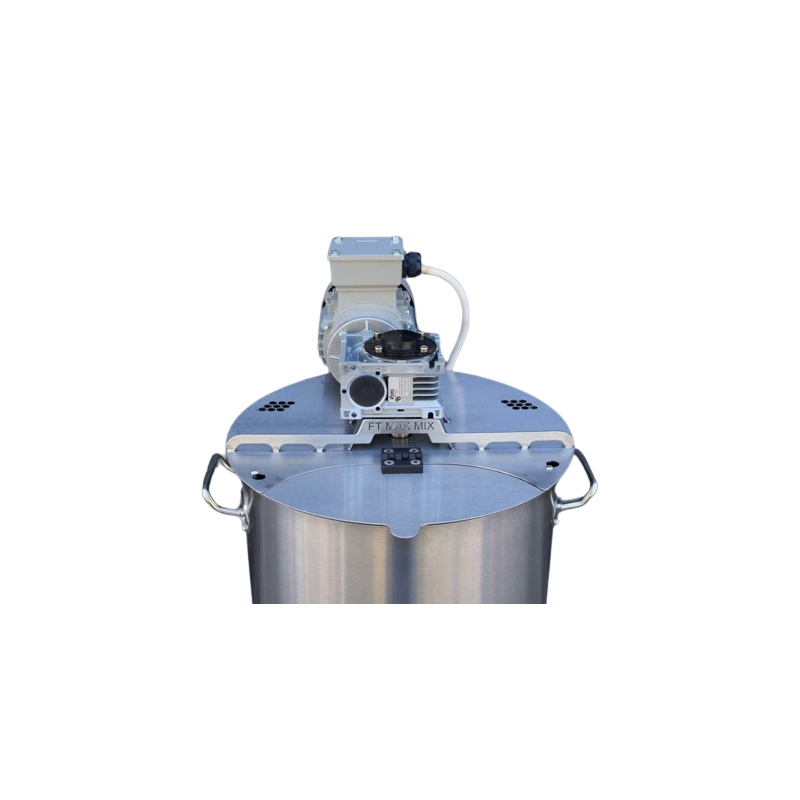

High speed mixing tank TurboMix

A universal vessel for mixing, whipping and stirring any products using a blade mixing device operating at high speeds.

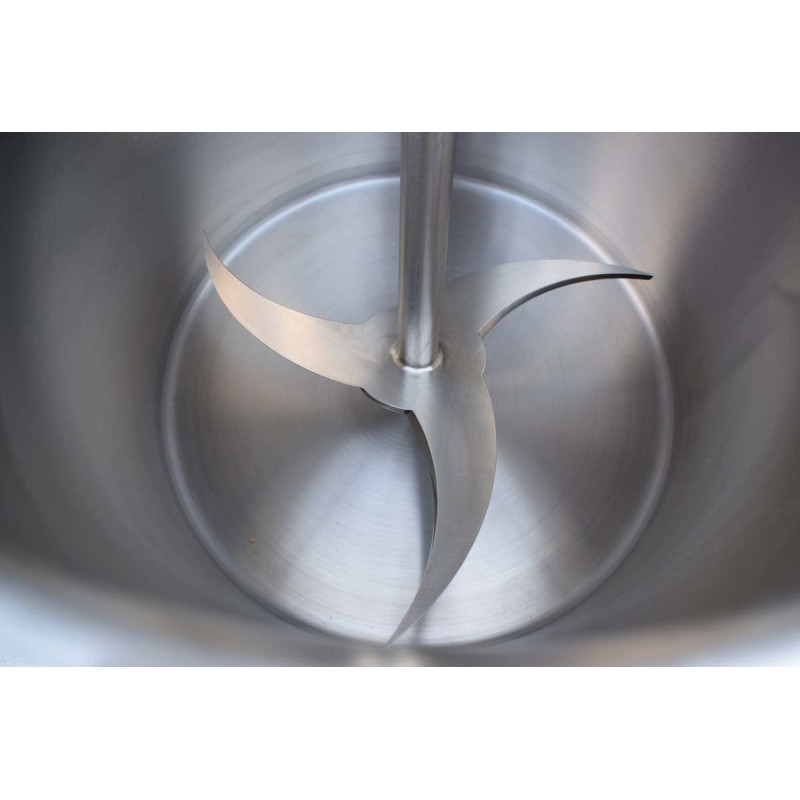

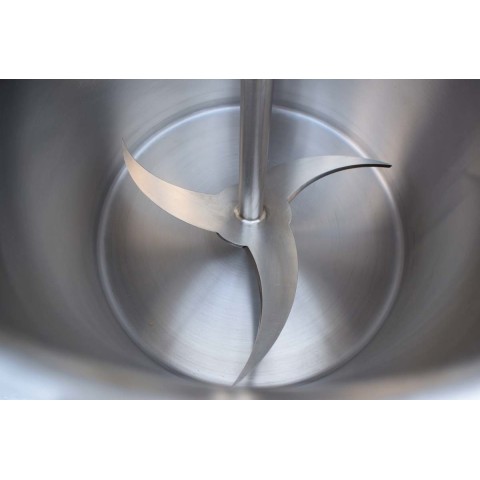

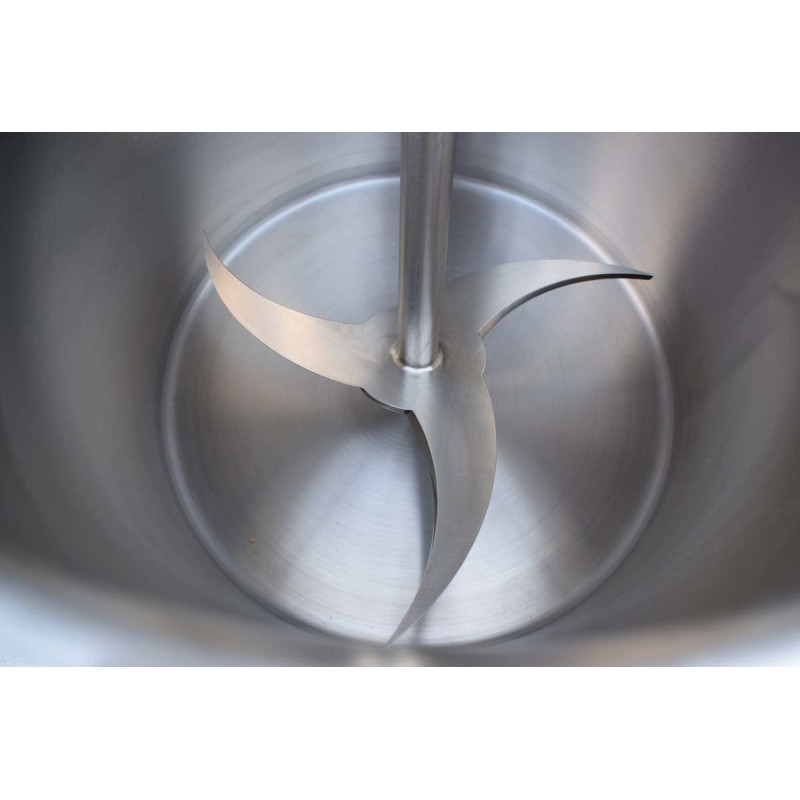

- Crescent shaped mixing device with three sharpened blades (cutter knives)

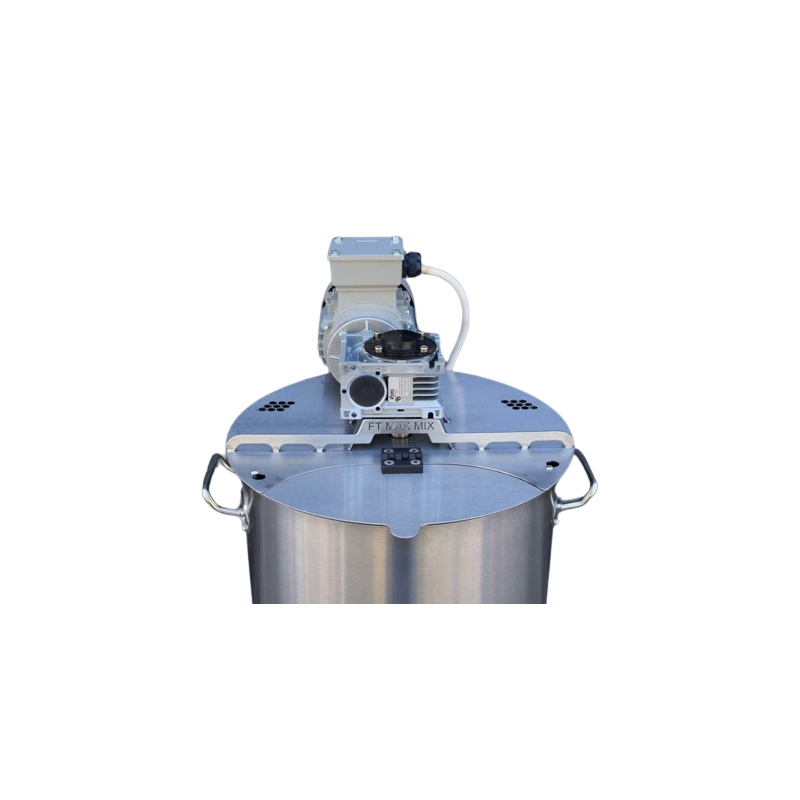

- Special high speed drive

- Sandwich bottom for all types of heating surfaces (electricity, gas, induction).

A mixer such as this, is one of the main devices utilized in large kitchens and catering facilities as well as small scale food production. This mixer with a high-speed stirrer allows for quick and efficient mixing of various liquid products to obtain solutions, multicomponent mixtures, dissolving powder ingredients in a liquid medium as for example, for the production of marinades.

Due to the fact that the mixing vessel has an additional option in the form of a heating source - an electric heating stool, mixing can be carried out simultaneously with the continuous thermal processing of the products.

With TurboMix you can easily mix products such as:

|

|

|

|

|

|

Advantages:

- High speed drive for cutting knives

- A special shape of the cutter knives on the mixing device, which effectively mix the product and prevent it from sticking to the bottom of the working container while effectively mixing a wide variety of ingredients

- Can be used with different types of heating surfaces for even more effective mixing, dissolving and stirring

- An easily removable lid with a stirrer for easy unloading of the finished product; just open two latches and remove the stirrer from the container.

- Safety grid - under the sectional opening lid there is a special grid with holes for safe visual monitoring of the process or adding small, liquid or bulk ingredients during operation.

Basic version

TurboMix is a stainless steel container with a wall thickness of 1 mm and a bottom thickness of 5 mm, which houses a specially shaped mixing device for effective mixing of components with a high rotation speed of the cutter's knives. The mixer is equipped with a quick-release lid that opens in sections for visual control of the process, it is also equipped with a safety mesh.

Additional options

Vertical mixing blade for mixing especially thick and sticky products.

Heating surfaces:

- electric "stool"

- gas burner

- Productivity: 50l/ 100l

- Material: Stainless steel

- Engine power, kW: 0,18/

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Diameter, mm: 400/ 500/ 600

You might also like

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

The durable single gas stove serves a versatile purpose, suitable for heating large cooking kettles. 7 kW.

- Heating: Gas

- Heating power, kW: 7

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Shaker mixer SMU6 is designed for mixing the contents of packaged products that are in foil or other protective packaging. The device is used in the food, pharmaceutical, chemical, construction and cosmetic industries, where it is necessary to thoroughly mix the contents without damaging the packaging.

- No need to remove the product from the packaging - mixing takes place in the original packaging

- Hygienic and safe mixing without contamination

- Robust and durable construction made of stainless steel AISI 304

- Material: Stainless steel

- Country of origin: Slovakia

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The AA50 adjustable industrial mixer is designed for efficient, high-performance mixing of liquid, viscous and pasty products, as well as for dispersing dry ingredients (pigments, dyes and other materials) in a liquid medium to obtain highly dispersed suspensions, emulsions and pastes.

- Material: Stainless steel

A spiral mixer with a fixed bowl and an electronic control panel. Available in various different capacities.

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 120 l/ 160 l/ 200l/ 250 l

- Voltage: 380-400V

The Z-Sigma Arm paddle mixer is designed for intensive mixing, stirring, kneading and plasticizing products with high and very high viscosity, such as chewing gum base, stiff dough with low water content, toffee mass, soap base, adhesives.

- Double Z-shaped blade

- Very high shear force

- Minimum gap between z blades and the working container

- Independent electric drive for each blade

- Electric tilting for automatic unloading up to 180 degrees

- The mixer is made entirely out of food grade stainless steel AISI304

- Possibility to choose the side of tilting and unloading

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 70l/ 140/ 300l/ 460/ 700l/

- Voltage: 380-400V

The price is indicated without the frequency converter

A twin-screw mixer for fast and intensive mixing, stirring of bulk solid products, such as granules, muesli with various powder additives.

- The mixing blades carefully move while thoroughly mixing the product

- The mixing mode allows you to move the product cyclically in a circle

- High mixing efficiency due to the counter-movement of the 2 shafts

- Compact design

- Possibility to install scrapers on each blade (optional)

- Reinforced drive, can be used for products saturated with moisture as well

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 500l

- Total power, kW: 3

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

This versatile 300 liter planetary mixer is a professional food processing equipment used for mixing, kneading, and blending ingredients in various culinary applications. It features a unique mixing action where the beater rotates on its axis while also revolving around the bowl, ensuring thorough and consistent mixing of ingredients.

The laboratory vacuum cutter mixer is designed for uniform grinding, emulsifying and mixing of food, cosmetic and pharmaceutical products, chemical mixtures with the addition of oil, dyes, concentrates or liquid flavors.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

- Engine power, kW: 3

- Principle of operation: Continuous mode

- Voltage: 380-400V

A universal homogenizing module for mayonnaise production. The special compact atmospheric unit with a bottom homogenizer and a circulation system allows to create stable fat emulsion in just a few minutes!

- Compact design

- No dead zones and corners due to the conical shape of the unit

- Powerful bottom inline homogenizer with circulation

- Hygienic design

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 300l

- Total power, kW: 9

The home cheese making unit is a simple and compact solution for producing homemade cheeses right in your kitchen or for small-scale food production, it can also be used as a laboratory unit for testing new cheese recipes in industrial factories. The unit is designed for processing milk and producing various cheeses and cheese-based products.

- Options to choose electric or gas heating (additional options)

- Special stirrer for automatic mixing, which prevents possible burning of milk

- Visual control during operation thanks to a special safety grid on the upper sectional opening hatch

- Quick-release lid with a stirrer for easy unloading of the product or cleaning of the unit

You can also choose a version of the cooking kettle with a thermometer and an outlet valve, making it suitable for milk pasteurization as well.

- Material: Stainless steel

- Engine power, kW: 0,12 0,18/ 0,25

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

Mixers are carefully designed, constructed and tested to handle a variety of industrial applications that require mixing, dispersive mixing, distributive mixing and more.

- Material: Stainless steel

- Country of origin: Slovakia

- Voltage: 380-400V

- Geometric volume: 500 l