Milk pasteurizer VAR E

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

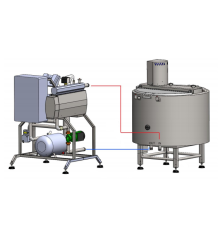

Milk pasteurizers can also be supplied with water heaters as an optional feature - these are external sources of hot water supply. The pasteurizer can also be used as a milk cooler if cold water is supplied to the unit's jacket from an external ice water station with a chiller (optional).

Suitable for heating, preheating, pasteurizing milk up to 95-98 degrees, as well as cooling milk when using a cold coolant. The installation serves as a universal solution for small milk processing plants, as it can change its functional properties depending on the coolant supplied into the jacket.

Suitable for the pasteurization or cooling of products such as:

|

|

|

|

Advantages:

- The unit is composed of high-quality materials made in Europe.

- The pasteurizer is made entirely out of food grade stainless steel AISI 304.

- 3-layer casing with thermal insulation and an external decorative casing.

- Temperature sensor for adjusting and monitoring the heat treatment temperature.

- The inclined paddle mixer is the ideal solution for both pasteurization and cooling of milk.

- Possibility of connecting a refrigeration unit and using the pasteurizer as a cooling tank for milk.

Basic Version

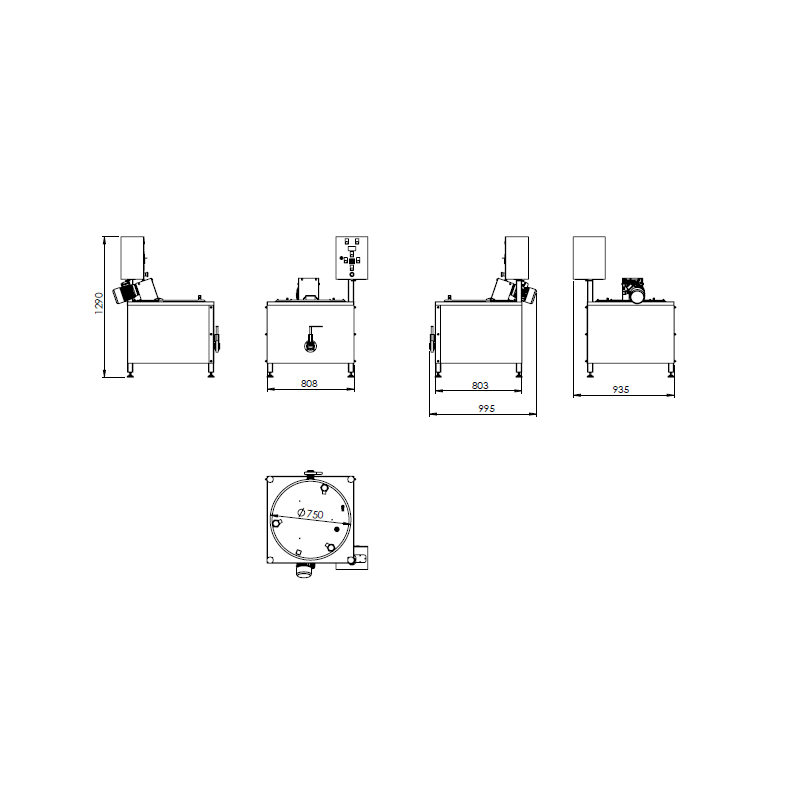

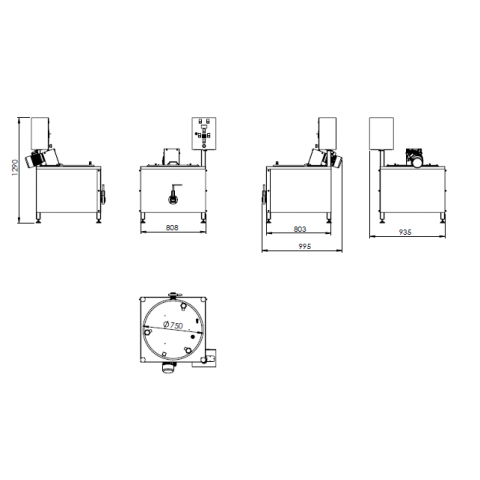

It comprises a three-layer stainless steel tank with thermal insulation, into the jacket of which coolant can be supplied under a pressure of up to 0.5 bar for indirect heating or cooling of the product. The pasteurizer is equipped with an inclined paddle mixer with an electric drive, a control panel, and height-adjustable legs.

Heating is carried out by supplying coolant into the jacket from an external source for heating or cooling, which can be offered as an additional option.

Operating Principle

Mixing of the product is ensured by an inclined paddle mixer. The upper housing opens by 1/3 using a hatch for loading raw materials. The finished product is discharged through a release valve located at the lowest hydraulic point

Options

- electric flow water heater

- steam generator

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

You might also like

Electric heating panel with three different power possibilities: 12, 24 and 48 KW ŌĆō excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

The generator is mounted on a stainless steel platform support, covered with stainless steel AISI 304 properly shaped with electrical and water connections already made. Stainless steel cocks AISI 316, malleable iron pipe fittings, feed water pump (mod. TP78A CALPEDA) with 1 stainless steel non-return valve, with VITON seal.

- Heating power, kW: 24/ 32/ 48

The pasteurizer equipment MGGP is suitable for the heat treatment of low viscosity liquids as well as drinking water.

- Productivity: 500 l/h/ 800 l/h

- Material: Stainless steel

- Principle of operation: Continuous mode

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

- Material: Stainless steel

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500l/ 650l

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. The 6-stage heating regulation of the powerful integrated heater, allows the milk to be reliably pasteurized directly in the container with a sandwich bottom, ensuring even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip it with a drain valve for discharging liquid products

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.┬Ā

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

Milk pasteurizer for small and medium-sized enterprises, designed to carry out the pasteurization process of milk and other liquid products.

- Precision and stability of temperature control

- Maintaining the set temperature

- Uniform heating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3/

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 100l/ 300l

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

- Material: Stainless steel

- Principle of operation: Continuous mode