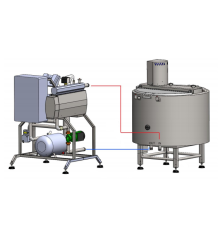

Plate type heat exchanger - pasteurizer PTP 500

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

The main advantage of this heat exchanger is its energy efficiency due to recuperation.

The basic version of the pasteurization system includes: a plate heat exchanger, consisting of two sections (for heating and recovery, which is used to cool the product to the "inlet" temperature), a screw pump-product and a double filtration system (single - for preliminary coarse filtration of honey near the inlet to the unit and a second one for fine filtration after heating).

The system is equipped with temperature and pressure sensors to adjust the honey flow rate. The size of the filter cell is selected additionally based on the properties of honey. Â

The filtration system is equipped with pressure sensors that indicate the degree of clogging of the filters. With fine filtration for continuous operation, a bypass is provided, the unit is equipped with two fine filters with the possibility of changing the flow. When one filter is clogged, the flow can be directed through the second filter and they can be cleaned without stopping the operation of the installation. To clean the unit, just open the filter, select the stainless steel cartridge, rinse it and put it back in.

Principle of operation:

Preheated honey is heated by supplying the heat carrier to the plate heat exchanger from an external source of hot water supply (additional option). Depending on the performance of the installation, the power of the heating system can range from 12 kW and up, based on the selected heating power.

The temperature of honey pasteurization depends on the âholdingâ time of the product, in plate honey pasteurizers it varies from 63 to 80 degrees, which can be adjusted by setting the operation of the product pump: the speed of honey flow through the plate heat exchanger.

After pasteurization, honey must be cooled. Honey is cooled using heat exchange processes between 30-degree honey at the inlet and heated honey after the fine filtration system (recovery), after which if necessary, it is enough to leave the honey to cool.

The plate heat exchanger can be easily dismantled, after work it can be disassembled and the plates washed.

Additional options:

- Hot water source

- Principle of operation: Continuous mode

- Country of origin: EU

You might also like

Electric heating panel with three different power possibilities: 12, 24 and 48 KW â excellent product manufactured by people who perfectly know the secret of product storage, maintenance and processing.

- Heating power, kW: 12/ 24/ 48

- Country of origin: EU

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

- Material: Stainless steel

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500l/ 650l

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

We offer different pasteurizers for different applications.

- Heating: Gas

- Productivity: 300 l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Country of origin: EU

- Voltage: 220-230V

The price is indicated with a semi-automatic control panel

The vacuum cooking kettle is designed for use in public catering establishments (restaurants, hotels, catering companies) and small manufacturing businesses. This equipment enables boiling, blanching, frying, evaporation, pasteurization, mixing or stirring.

- A unique multifunctional device

- Possibility to cook/fry under atmospheric or vacuum conditions

- Laboratory version of a Vacuum Fryer

- Built-in condensation and secondary steam removal system

- Intense electric heating

- Sectional basket with a lid

- Built-in system for separating and removing excess liquid from the product

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Volume: 20l

- Oil volume: 8l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

Milk pasteurizer for small and medium-sized enterprises, designed to carry out the pasteurization process of milk and other liquid products.

- Precision and stability of temperature control

- Maintaining the set temperature

- Uniform heating

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3/

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 100l/ 300l

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

A milk pasteurizer is designed for quick and effective pasteurization of milk, where the heating of the product in the working container is achieved by supplying hot water into the jacket.

- Special mixing device

- Large outlet valve at the lowest point of the pasteurizer

- Insulation of the working container to reduce heat loss during pasteurization

- Compact installation

- The control panel is located directly on the unit's body

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 300l

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode

The cheese boiler is used in the dairy industry for the production of cheese grains during the production of natural hard, semi-hard, soft cheeses, and other cheese or curd products. The cheese maker is equipped with a special knife-mixer (lyre) for cutting the cheese curd. Suitable for both small and large scale production. Using this cheese-cooking boiler you can also pasteurize other dairy products, produce yogurt, cottage cheese kefir, fermented baked milk, varenets, sour cream and more.

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

Pasteurizer, cheese boiler is designed for processing milk, yogurt, fruit juice or other liquids.Â

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Volume: 200l/ 300l/ 500l

The price is indicated without the heating and cooling sources

The continuous heat treatment and filtration unit is suitable for processing products of various viscosities, such as honey, jam, baby food, sauces, ketchup, tomato soup and many other products. Depending on the model, it can have a productivity ranging from 250 up to 2000 kg/hour.

- Universal application for continuous pasteurization

- Suitable for pasteurization of heat-sensitive products

- Ideal solution for thick and viscous products

- For short-term pasteurization followed by cooling

- Productivity: 250 kg/h/ 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Principle of operation: Continuous mode

- Country of origin: Slovakia