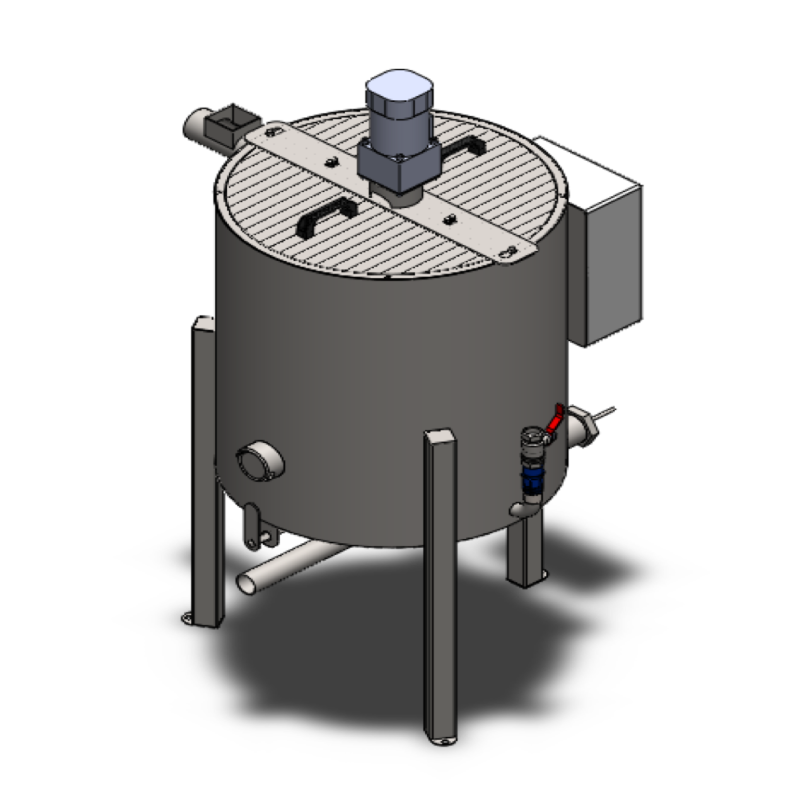

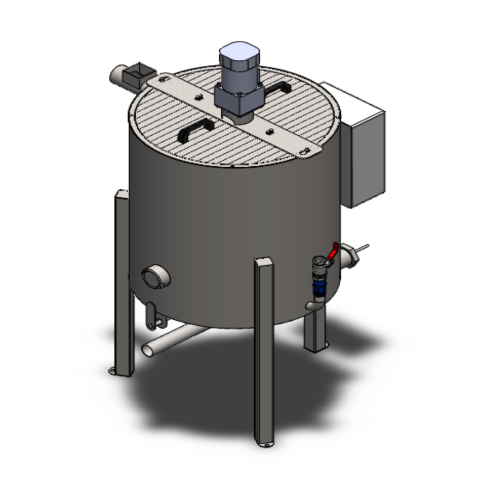

Milk pasteurizer

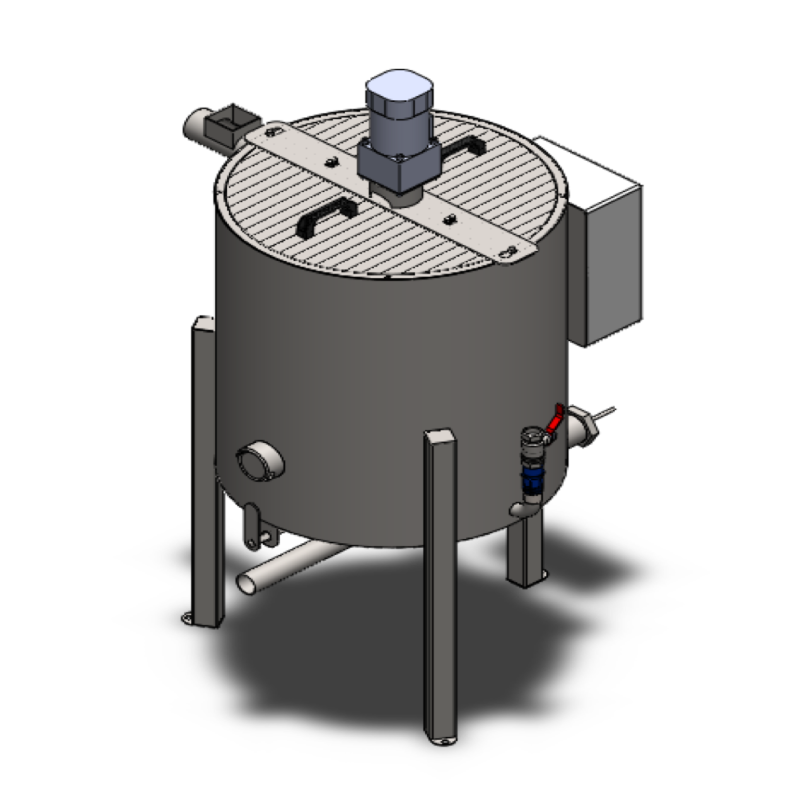

Milk pasteurizer for small and medium-sized enterprises, designed to carry out the pasteurization process of milk and other liquid products.

- Precision and stability of temperature control

- Maintaining the set temperature

- Uniform heating

A 100-liter milk pasteurizer is ideal for the needs of small and medium-sized enterprises. In addition to milk, it can also be used to pasteurize other products:

|

|

|

|

Advantages:

- Precision and stability of temperature control

- High energy efficiency

- Uniform heat distribution

- Hygienic and easy to clean

- Versatility - suitable for liquid products requiring pasteurization

- Durability and reliability - made from high-quality materials and components resistant to corrosion and wear

- Compactness - does not require a large area in production facilities

Basic version

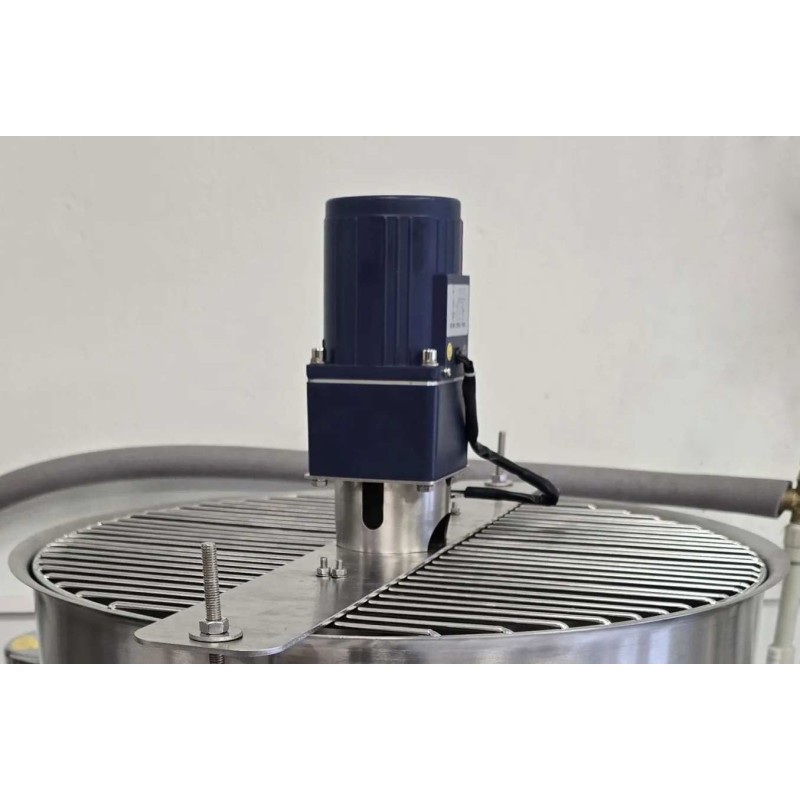

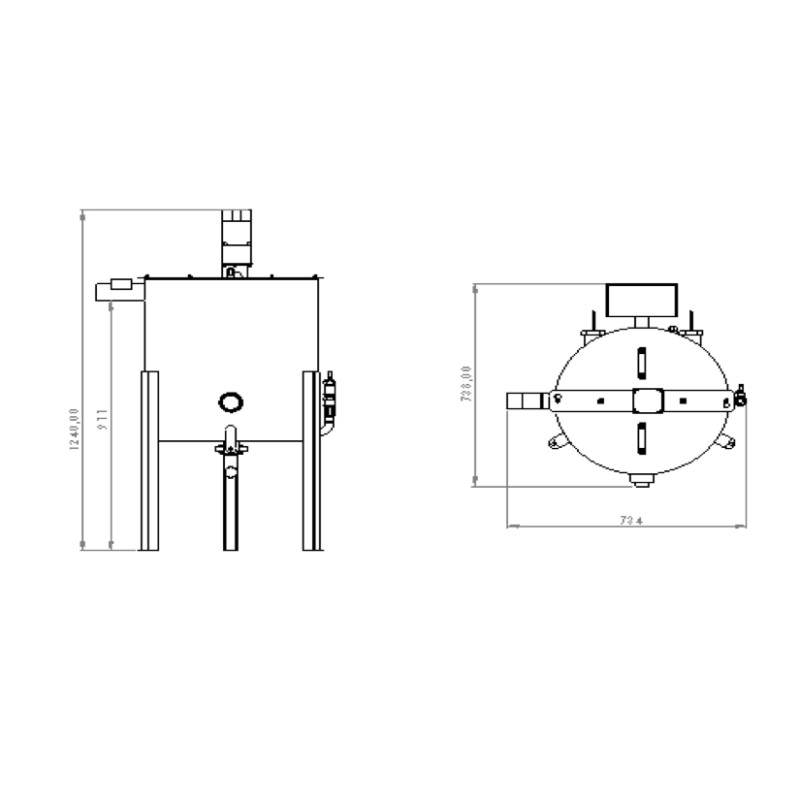

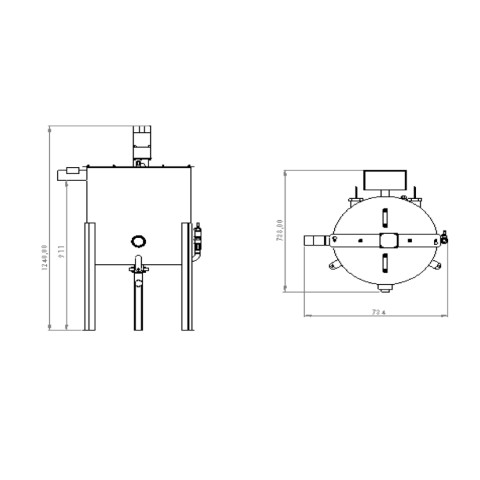

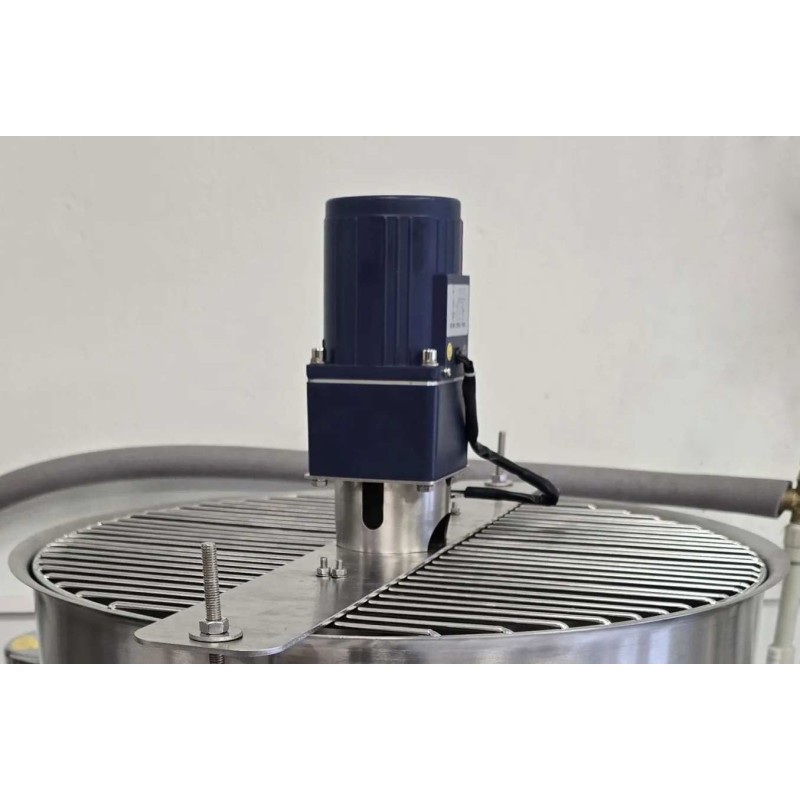

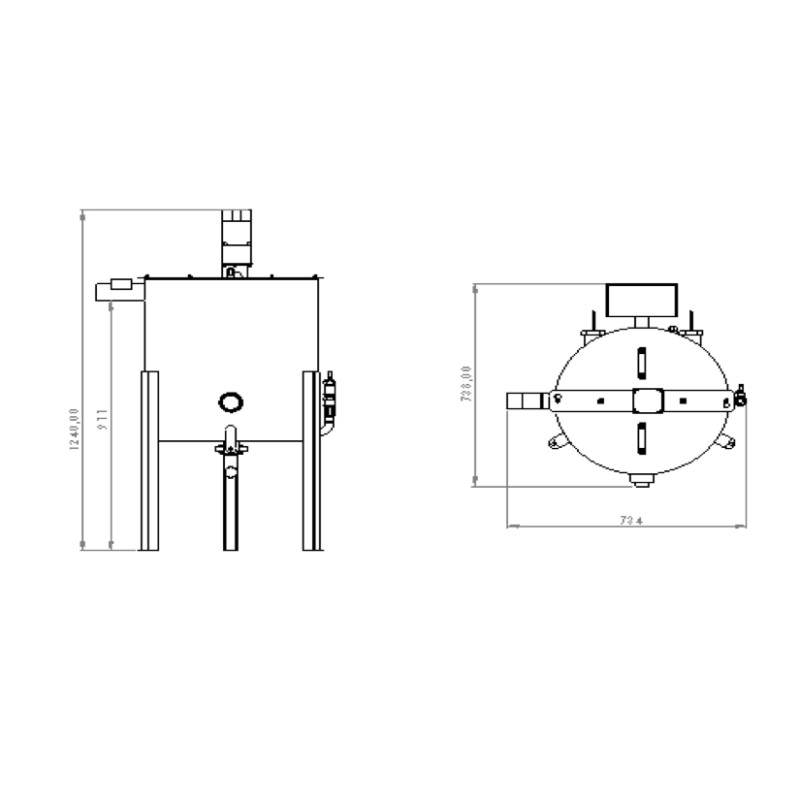

The basic version of the pasteurizer includes a working tank with a discharge ball valve, a mixing device, a thermometer, a lid, 2 heating elements of 3 kW each.

Operating principle

A milk pasteurizer is a device designed to destroy pathogenic microorganisms in milk through controlled heating. Milk is heated to a preset temperature - typically 72-75┬░C, held at that temperature for 15-30 seconds and then rapidly cooled to 4-6┬░C to prevent bacterial growth.

Options

- PLC control

- Wheeled support

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3/

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

- Volume: 100l/ 300l

You might also like

The concentration and thickening line line has been especially designed for industrial dairy production facilities with a small surplus of milk or smaller milk processing businesses that want to expand their product range. It has an estimated productivity of up to 50-120 kg/hour during continuous operation.

- Professional industrial technology with compact dimensions

- A large number of additional equipment and options to choose from

- Material: Stainless steel

- Principle of operation: Continuous mode

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The long-term pasteurization tank is a compact solution for the heat treatment of milk in order to disinfect the microflora and eliminate harmful microorganisms. This unit belongs to the category of long-term pasteurization systems, heating milk between 63 and 95 degrees Celsius, and maintaining it at a specific temperature for a set period of time. The special design allows not only for pasteurization of milk in the flow, but also for sequential cooling, by feeding cold water into the heat exchanger after heating.

- External forced circulation with a heat exchanger

- Highly efficient steam heating via the heat exchanger

- Can also be used as both a pasteurization and cooling unit

- High-performance milk pump

- Compact vertical design

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1000l

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

Electric pasteurizer suitable for pasteurizing beverages as well as filling up bottles or bag-in-boxes. We offer 3 production capacities. The basic pasteurizer model comes without the manual BiB filler module.

- Productivity: 180 l/h / 300l

- Material: Stainless steel

- Principle of operation: Continuous mode

- Voltage: 380-400V

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

Beverage Pasteurizer SB 750 refers to chamber types of pasteurizers used to pasteurize bottled beverages.

- Material: Stainless steel

- Principle of operation: Batch mode

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. Thanks to the 6-stage heating regulation of the powerful integrated heater, milk can be reliably pasteurized directly in a container with a sandwich bottom, which ensures even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip with a drain valve and a cooling/heating jacket (duplicator)

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

We offer different types of dairy pasteurizers. Tell us if you are producing cheese, milk, yoghurt or ice cream and we will help you pick the right pasteurizer for you.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: EU

- Volume: 200l/ 300l/ 500 l/ 800 l / 1000l

For a price quote or for a free consultation, send us a request.

- Productivity: 90l

- Material: Stainless steel

- Heating power, kW: 6/

- Principle of operation: Continuous mode

- Voltage: 380-400V

The price is indicated without the heating and cooling sources

The continuous heat treatment and filtration unit is suitable for processing products of various viscosities, such as honey, jam, baby food, sauces, ketchup, tomato soup and many other products. Depending on the model, it can have a productivity ranging from 250 up to 2000 kg/hour.

- Universal application for continuous pasteurization

- Suitable for pasteurization of heat-sensitive products

- Ideal solution for thick and viscous products

- For short-term pasteurization followed by cooling

- Productivity: 250 kg/h/ 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Principle of operation: Continuous mode

- Country of origin: Slovakia

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220