Milk pasteurization kettle MAK MIX

The pasteurization kettle with manual tilting is a modern device designed for gentle heat treatment of milk and dairy products, which allows for their effective pasteurization, extends shelf life and increases safety, while preserving the original taste and nutritional values. Thanks to the 6-stage heating regulation of the powerful integrated heater, milk can be reliably pasteurized directly in a container with a sandwich bottom, which ensures even heat distribution.

- Ideal solution for small-scale and home production of dairy products

- Removable lid for easy inspection and manual mixing of the product

- Option to equip with a drain valve and a cooling/heating jacket (duplicator)

- Even heating without burning thanks to the sandwich bottom

- Easy connection to a single-phase 230 V power supply

The pasteurization kettle with a tilting system is an effective solution for the heat treatment and stabilization of milk and dairy products.

This tilting pasteurizer is ideal for small producers, farmers, artisanal milk processors who want to obtain consistent results or for home production of cheese, yogurt and other dairy products. It allows for simple and reliable pasteurization of milk directly in a stainless steel container with a sandwich bottom, which guarantees even heat distribution, reducing the risk of burning the product. The temperature can be monitored with an optional thermometer.

The device can also be used for the pasteurization of sauces, jams, syrups, juices or soups, where it is important to preserve the natural taste, color and quality.

Thanks to the removable lid, the product can be visually inspected during pasteurization and manually stirred using a hand harp, which simplifies the production of cheeses and other dairy products. Optionally, the device can be equipped with a drain valve for convenient draining of the finished product or whey. Another option is a jacket (duplicator), through which cold water can be supplied for faster cooling after pasteurization.

The basic version of the device is equipped with an electric heater with a power of up to 2.6 kW, which can be connected to a single-phase 230 V power supply, without the need for a three-phase industrial electrical connection.

Suitable for:

- pasteurization of milk, cream and whey

- production of cheese and yoghurt

- pasteurization of syrups, sauces, broths, juices and juices

- heat treatment of baby food or plant-based drinks

Advantages:

- Compact and robust device suitable for domestic and commercial use

- Hygienic all-stainless steel design made out of food-grade AISI 304 steel

- Even heating without burning thanks to the sandwich bottom

- Removable lid - easy cleaning and possibility of visual inspection during pasteurization

- Manual stirring (e.g. harpfo) option when producing cheese or yoghurt

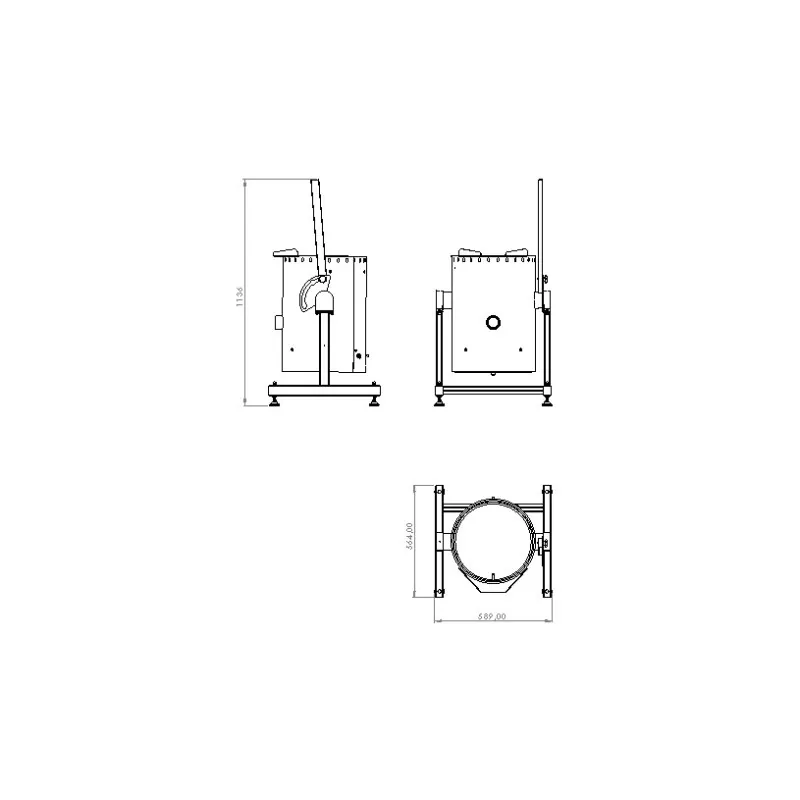

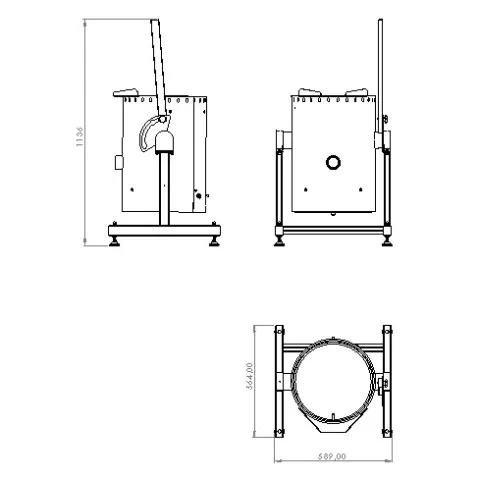

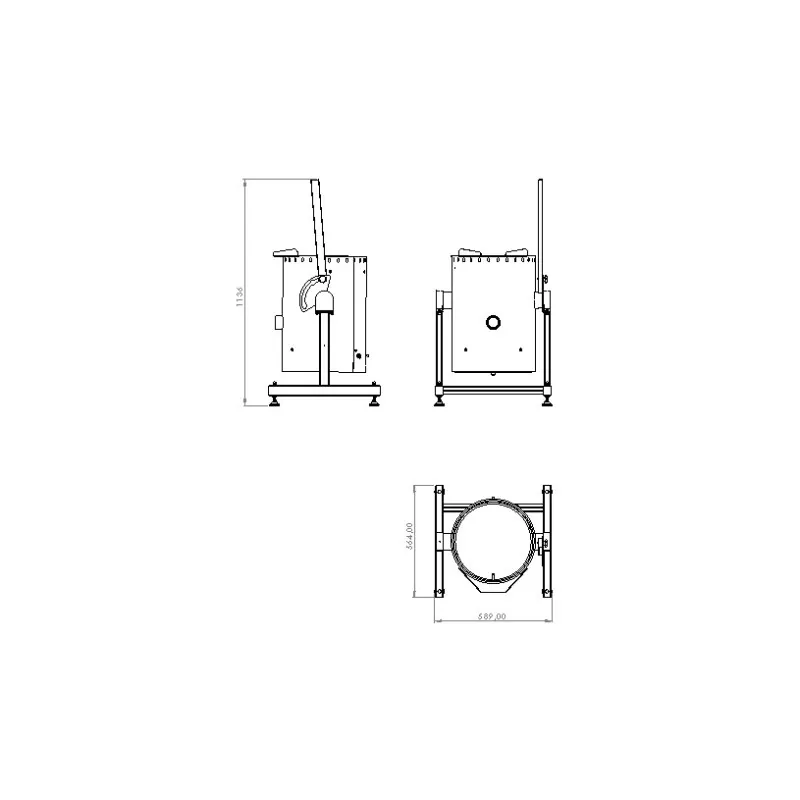

- Manual tilting system with 3 working positions and an angle of up to 110┬░ for easy emptying of the container

- Safe heating - 2600 W, single-phase power supply (230 V)

- Optional: drain valve for draining the product or whey

- Optional: cooling via a water jacket (duplicator) for faster cooling

The basic version includes:

- Pasteurization vessel with an insulating jacket

- Support structure with a manual tilting system (3 positions, angle up to 110┬░)

- Integrated heating with a power of up to 2.6 kW

- Precise temperature sensor located directly in the product or on the lid

- Wheels for easy transport of the device (optionally, legs can be selected)

Principle of operation:

Milk or other product is poured into the vessel, where it is gradually heated to the desired temperature. The layered bottom ensures uniform heating without burning and stable temperature maintenance throughout the entire pasteurization phase.

After the specified time, the product can be cooled either naturally or, in the version with a duplicator - by means of supplying cold water into the duplicator. After the process is finished, the container is simply emptied by tilting it manually or via the optional drain valve.

Optional equipment:

- Drain valve for the finished product or whey

- Jacket (duplicator) for cold water supply

- Height-adjustable legs instead of wheels

- Frequency converter as a control panel for mixing adjustment (IP66)

- Submersible and removable thermometer through the container lid

Technical characteristics:

- Material - Stainless steel AISI 304

- Volume - 50 / 100 l

- Heating power - 2.6 / 5 / 6.5 kW

- Power supply - 230 V (1-phase) or 400 V (3-phase, for higher powers)

- Pasteurization temperature - up to 100 ┬░C

- Material: Stainless steel

- Heating power, kW: 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

You might also like

A cheese kettle is a specialized cooking vat used in cheese making processes to heat and curdle milk, allowing the separation of curds and whey. It provides controlled heating and agitation to facilitate the cheese production process. Working volume up to, l: 300 l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 300 l

The price is set for the basic version of the vacuum evaporation unit with basic controls (mixer motor switch) and without additional options. The control unit is customized based on individual customer requirements. The pump is also selected separately depending on the product.

A compact vacuum evaporation unit that allows you to concentrate solutions, mixtures, and various products by evaporating the solvent. A modular version based on the basic version of the 110/100 vacuum reactor.

- Gravity mixing - 25% more efficient

- Reinforced agitator design with no blind spots

- Bottom ball valve with no dead zones

- Condensation and secondary vapor removal system

- Easy to disassemble mixing device

- Large heat exchange area

- Ability to measure and monitor condensate volume (optional)

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

- Working volume: 50-80l

- Condensing capacity, l/h: 45-55

- Steam consumption, kg/h: up to 150

Equipment for the production of condensed milk from pre-pasteurized milk. This equipment can be manufactured with a capacity of 50 to 500 kg/hour, or on request. We also manufacture condensed milk lines according to TU from dry milk┬Āor┬Ānormalized milk concentration lines.

- Material: Stainless steel

- Type of the equipment: Part of a production line

- Country of origin: Slovakia

A compact electric pasteurizer with a heating power of 5 kW is used for long-term batch pasteurization of milk, which includes heating milk to a temperature up to 100 degrees C and maintaining it for a selected period of time. The milk pasteurizer can also be used in the form of a Milk pot to heat milk for feeding calves.

- High heating power (5ŌĆ»kW) on a 220ŌĆ»V single-phase connection

- Stirrer with bottom scrapers that prevents milk from burning when directly heated

- Direct electric heating with a multi-stage power switch

- Hygienic design for simple and easy cleaning

- Simple system for removing and lifting the top hatch with an agitator

- Absence of blind spots where bacteria can grow

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Heating power, kW: 5

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Tell us if you are producing cheese, milk, yoghurt or ice cream. The difference between the milk pasteurizer and the yoghurt pasteurizer is that the yoghurt pasteurizer is equipped with a detachable arm with a detachable big stirrer and two half lids.

- Material: Stainless steel

- Country of origin: EU

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500 l/ 650l 800 l / 1000l/ 1250l/ 1500l

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.

The pasteurization equipment MGGP is suitable for the heat treatment of low viscosity foods as well as drinking water.

- Productivity: 500 l

- Material: Stainless steel

- Principle of operation: Continuous mode

MIP Y Pasteurizers are designed for the thermal processing of milk, for the production of yoghurt, white cheese (feta), hard cheese, ice cream and many other milk products.

- Material: Stainless steel

- Volume: 50l/ 100l/ 200l/ 300l/ 400l/ 500l/ 650l

The device is designed for the pasteurization of a wide range of products in various types of packaging material such as cans and jars.

- Heating: Mixed

- Productivity: 300 l 400 l 500 l

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The price is indicated without the heating and cooling sources

The continuous heat treatment and filtration unit is suitable for processing products of various viscosities, such as honey, jam, baby food, sauces, ketchup, tomato soup and many other products. Depending on the model, it can have a productivity ranging from 250 up to 2000 kg/hour.

- Universal application for continuous pasteurization

- Suitable for pasteurization of heat-sensitive products

- Ideal solution for thick and viscous products

- For short-term pasteurization followed by cooling

- Productivity: 250 kg/h/ 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Principle of operation: Continuous mode

- Country of origin: Slovakia

A vat or cooking kettle for milk is a large container or vessel used for heating and processing milk, typically in dairy production, to pasteurize, cook, or produce various dairy products such as cheese or yogurt.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 500l/ 1000l

This multifunctional cooking machine is designed to be used in a variety of different ways and is suitable for the majority of professional kitchens and catering businesses - any small enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Voltage: 380-400V

The electric pasteurizer is ideal for the heat treatment of various fruits, including apples, pears, blackberries, strawberries, blueberries, elderberries, currants, carrots, greens, quince, beets, sea buckthorn, rowan berries, and onions.

- Material: Stainless steel

- Principle of operation: Continuous mode

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

The plate pasteurizer is designed for partial decrystallization and pasteurization of honey preheated to a temperature of 30-35 degrees.

- Principle of operation: Continuous mode

- Country of origin: EU

This multifunctional cooking machine with two baskets is designed for different ways of use and is suitable for a lot of variety of businesses - any enterprise or any participant of the HoReCa market. With the help of this equipment, you can cook, pasteurize, or blanch.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 135 +135 / 220+220

Pasteurization dipping tub is suitable for the heat treatment of packaged fruit preparations, (jams, fillings, hams) or fermented preparations (vinegar, beer) and pickles to preserve them, and to eliminate harmful microorganisms.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

The tubular pasteurizer is typically designed for pasteurizing cream in butter production lines. These pasteurizers are commonly used in dairy processing industrial facilities, especially in butter production and other related sectors.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

We offer many different types of pasteurizers.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The professional yogurt making machine is designed to produce a wide range of yogurt production, e.g. creamy, liquid drinking, greek, white, organic, fruit yogurts. The machine can be used by farms and small dairy factories.

- Material: Stainless steel

- Principle of operation: Batch mode