Fruit Apple washer is designed for washing and cleaning products such as fruit or vegetables before processing.

Product in the washer is washed with water and soft brushes which leave it intact. Equipment designed for use in the food industry for fruit and vegetable processing.┬Ā

FRUIT WASHING EQUIPMENT - MAIN FEATURES:

- Mounted on pivoting wheels.

- Brushes made of non-toxic material.

- Detachable brushes for easy cleaning after use.

- Easy cleaning of the whole washer after use.

- Washer cover can be opened.

- Speed regulation with frequency converter ŌĆō the speed of the washer dictates the capacity of the processing line.

- Gradual exchange of water during washing: inflow of fresh water at the exit of fruits from washer, outflow of wastewater at overflow at the entrance of fruits in the washer.

- Long slide at the outlet for draining fruits and removal of impurities (e.g. leaves).

- Material: Stainless steel

- Principle of operation: Continuous mode

You might also like

The machine is used for brushing, cleaning as well as prewashing various root vegetables.

- Material: Stainless steel

- Engine power, kW: 2,2

The fruit mash pump is designed for efficiently transporting mashed fruits from a crusher to a press for extracting juice.

- Productivity: 6000 kg/h

- Material: Stainless steel

- Engine power, kW: 1,85

- Voltage: 380-400V

The fruit destemming machine eliminates seeds and kernels from the fruit's core, preparing it for subsequent processing.

- Productivity: 500 kg/h/ 1000 kg/h/ 2000 kg/h

- Material: Stainless steel

- Engine power, kW: 2,2/ 5,5

- Principle of operation: Continuous mode

Pneumatic fruit presses are intended for smaller winemakers who want to produce high quality wine. Price depends on your production parameters.

- Material: Stainless steel

- Principle of operation: Continuous mode

The mill is designed for milling whole fruit or vegetable before further processing. Price depends on the chosen fruit and production capacity.

For more information, send us a request.┬Ā

- Productivity: 6000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

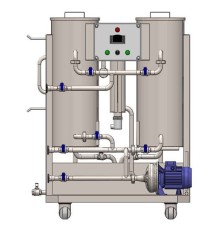

Clean-in-place (CIP) is a method of cleaning and disinfecting the internal surfaces of pipes, containers, water tanks as well as industrial equipment, filters, related fittings and other accessories without the need for disassembly.

- Material: Stainless steel

- Volume: 2x50 l/ 2x100 l/

The CEP washing machine is a mobile cleaning station designed to efficiently clean various containers, including mixers and boilers, suitable for use in the food, chemical, and pharmaceutical industries.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Weight: 85

We offer a wide range of washing equipment tailored to diverse food products, ensuring optimal cleanliness and preparing your fruits and vegetables for the next processing stage.

- Productivity: 2000 kg/h 3000 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: EU

- Productivity: 300 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Type of the equipment: Individual machine

- Productivity: 800 psc/h

- Material: Stainless steel

- Operation mode: Semi-automatic

Compact universal washing and spin-drying unit designed for gentle and effective cleaning of fruits and vegetables. The system combines adjustable whirlpool washing with centrifugal drying, allowing efficient removal of soil, dust, and water in just a few minutes. Constructed entirely from food-grade stainless steel, it ensures hygienic operation and easy cleaning. Ideal for restaurants, hotels, catering kitchens, and small food processors.

- Efficient combined washing and drying process - total cycle under 5 minutes

- Adjustable washing intensity for delicate or firm products

- Stainless steel perforated drum for thorough cleaning and durability

- Integrated spin dryer for quick water removal and extended product shelf life

- Compact, easy-to-clean design with low water and energy consumption

The drum washer is designed for washing potatoes and other roots as well as for seeds, nuts and grains.

- Material: Stainless steel

- Engine power, kW: 1,1

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Improve the cleaning process with the CIP-53, a mobile station designed for thorough sterilization and sanitation of vessels and pipelines. Ideal for breweries and the food industry, this comprehensive system with three 50 or 100 liter tanks ensures efficient cleaning of fermentation and storage tanks, offers digital temperature control and neutralization.

- Material: Stainless steel

- Voltage: 380-400V

Washing tank with wheels with conveyor belt for fruits and vegetables.

- Material: Stainless steel

- Engine power, kW: 2,4/

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 330 mm

- Voltage: 380-400V

CIP-52: Clean-In-Place - Machine for cleaning and the disinfection vessels and pipelines in breweries and other food processing plants with two 50 liter tanks.

- Material: Stainless steel

- Country of origin: EU

We offer different types of washing equipment for various different fruits and vegetables.

- Productivity: 1500 kg/h

- Material: Stainless steel

- Engine power, kW: 3

- Weight: 200

Vegetable washers are designed to clean and prepare vegetables for consumption or further processing.

We offer different types of vegetable washers.

- Material: Stainless steel

- Engine power, kW: 0,47 / 1,45 / 1,85

- Type of the equipment: Individual machine

- Country of origin: EU

- Volume: 160 l/ 300l/ 600l/

Bubble washer for gentle washing and cleaning of fruits and berries, for example peaches, cherries, strawberries and other raw fruits prior to their further processing.┬Ā

- Principle of operation: Continuous mode

- Country of origin: EU

- Working Area Width: 600 mm/ 800 mm/ 1000 mm

The brush washer/scraper is an industrial device for washing and scraping root vegetables depending on the degree of contamination.

- Productivity: 300 kg/h

- Material: Stainless steel

- Engine power, kW: 1

- Voltage: 230 V/ 380-400V

Keg washing and filling machine used for washing and filling kegs and barrels for beer, cider, wine and other beverages.

- Material: Stainless steel

- Engine power, kW: 0,75

- Operation mode: Manual

- Voltage: 220-230V 380-400V

The washer with external loading conveyor UNI M is specifically designed for the efficient and high-performance washing of vegetables, potatoes, and fruits, using gentle exposure to water to ensure thorough cleaning without harming the product.

- Material: Stainless steel