Industrial vacuum cooking kettle VAC U 1000

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

The batch vacuum┬Ākettle is designed for cooking caramel, toffee mass, condensed milk, fudge, gum base, as well as fillings, jellies and marmalades, and mixes of soft varieties of sweets.

Using a vacuum during the cooking process allows it to reduce the processing time and temperature, which is necessary for adding heat sensitive ingredients.

It is ideal for cooking light toffee and caramel masses without the browning effect often associated with cooking these types of sweets. The capability of atmospheric and vacuum cooking makes VAC-U 1000 the ideal solution for a variety of technological tasks.

Ongoing Processes:┬Ā

- mixing

- dissolving

- pre-cooking

- cooking

- deaerating

- caramelizing

- vacuuming

- tempering

A system of dosed ingredients to be added is supplied. This is not included in basic supply scope and can be offered as option.

Soft And Smooth Caramel The design and form of the vacuum cooker was developed in collaboration with leading process engineers with years of practical experience in the production of toffee and caramel masses.

This succeeded in achieving the optimal in the processes of moisture removal and caramelization.

The finished product has a smooth homogeneous structure. Can be equipped with all necessary equipment to complete the production cycle:

- Storage tanks for ingredients (syrup, condensed milk ŌĆ”)┬Ā

- Sugar syrup cooking plants z Measuring tanks z Mixer units

- Dosing machines and more.

Our experience in manufacturing process equipment for the production of caramel, toffee and jelly masses allows us to offer customers full cycle equipment with various levels of automation, including fully automated lines with minimal operator involvement.

The heat transfer medium can be: steam, thermal oil or heated water.┬Ā

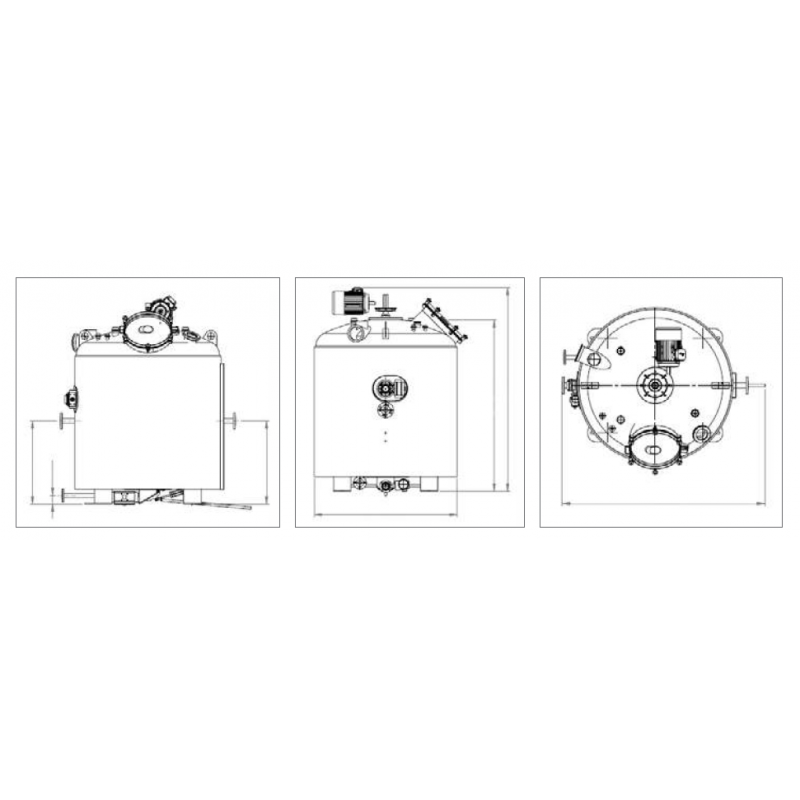

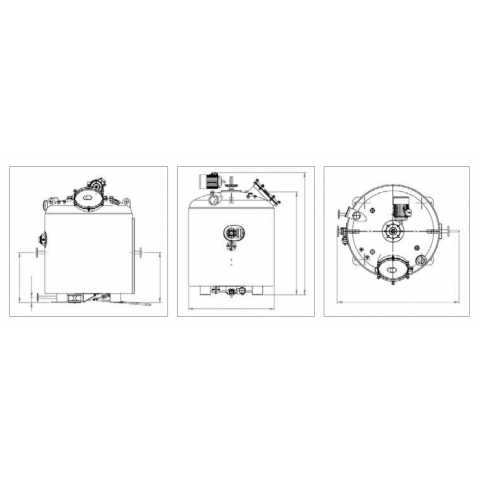

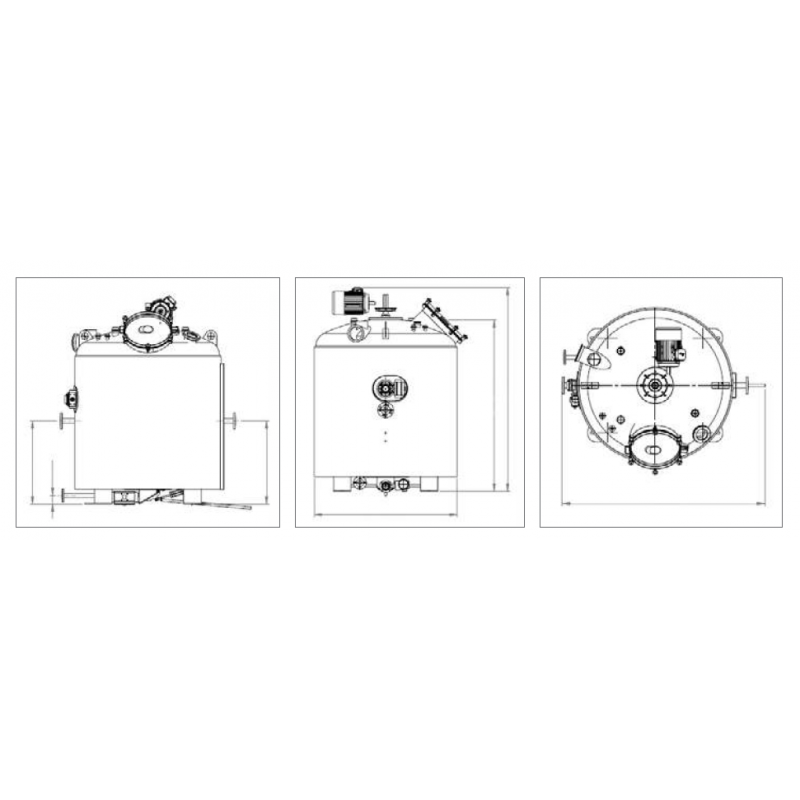

Design The design of the vacuum cooker consists of thermally insulated cylindrical vessel equipped with an agitator with scrapers specially shaped for effective mixing of viscous products and dissolving ingredients. The cookerŌĆÖs cover is equipped with a hatch to insert ingredients, processing fittings according to the customerŌĆÖs specifications. There is also an inspection glass, connecting fittings for CIP system, a vacuum gauge, a vacuum controller and steam condenser. At the bottom of the vacuum cooker is the specially designed bottom valve (with manual, pneumatic or mechanical drive, with mechanical locking), guaranteeing the absence of a dead zone when unloading the product.

The basic configuration includes a temperature sensor, gauge and torch lights.

The vacuum cooker VAC-U 1000 comes complete with a vacuum station and condensate recovery system.

Advantages:

- The high quality of the finished product. Thanks to the special form of the cooking vessel, the processes of moisture removal and caramelization take place as efficiently as possible, thereby reducing the cooking time of the confectionery mass and therefore improving the quality of the finished product.

- Vacuum execution allows cooking and water evaporation at lower temperatures, eliminating scorching and overcooking of the product. The finished product has a natural rich flavor with maximum preservation of flavoring substances. There is also the possibility of adding heat-sensitive ingredients.

- Economy. The excellent performance of heat exchange provides rapid heating that significantly reduces energy consumption for cooking in one batch.

- Ease of use. Ingredients are conveniently inserted through the top hatch or load fitting. The finished product (thick mass) is conveniently unloaded through the highly hygienic bottom outlet valve.

- Hygiene. The design of the vacuum caramel cooker is convenient for cleaning and maintenance. It is highly hygienic, with no dead zones. CIP cleaning.

- An automatic control system provides control over all processes in accordance with prescribed recipes.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

You might also like

Heating: integrated electric. Price depends on the production capacity and product.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

This automatic cooking machine is made for continuous production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basketŌĆÖs design.

- Material: Stainless steel

- Operation mode: Automatic

- Volume: 300l/ 600l/

- Voltage: 380-400V

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

The stated price does not include the steam generator

The unique sectional cooking kettle is intended for high-performance cooking/blanching/frying of a wide range of products with subsequent cooling to avoid damaging their structure. An essential part of this technology is the efficient cooling section, necessary for halting the cooking process after unloading. This function is also necessary when processing vegetables to the "aldente" state, when vegetables retain their structure and natural color after thermal treatment. This model provides heating by direct injection of purified steam into the heating section (steam generator - option).

- Suitable for cooking small-sized products

- Fast and intense heating due to direct steam injection

- Intensive hydro-stirring

- Automatic basket lifting system

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 2x250l/ 3x250l

- Voltage: 380-400V

- Working volume: 2x175l/ 3x175l

The cream-cooking kettle with manual tilting is designed for controlled heating, concentration, and thermal treatment of cream and cream-based products. Its adjustable temperature control, gentle handling, and uniform heat distribution enable processes such as thickening, reduction, pasteurization, and the preparation of dessert bases.

- 6-stage heating intensity adjustment

- Uniform heat distribution for a consistent product consistency

- Manual tilting system for complete and convenient emptying

- Suitable for cream, dairy desserts, sauces, and similar products

- Smooth stainless steel interior for easy cleaning and maintenance

A professional cooking boiler with built-in intensive bottom heating and a tilting system for the working container allows you to quickly heat the product to high temperatures (200┬░C). Suitable for blanching, boiling, frying and stewing various products where high-temperatures and efficient processing is required.

- Powerful bottom heating with uniform heat distribution (2600 / 6500 W)

- Professional stainless steel probe in the product with a thermometer for visual control

- Compact standing supporting structure for safe operation

- Three-stage adjustment of the tilt angle of the working container

- The unit is made entirely out of stainless steel

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 3,5/ 6,5

- Volume: 50l/ 100l

- Voltage: 380-400V

This automatic cooking machine is made for continuous production. Different types of food can be boiled, like pasta, rice (minimum 1.5 mm in size), vegetables, meat etc., thanks to the basketŌĆÖs design.

- Material: Stainless steel

- Operation mode: Automatic

- Volume: 300l/ 600l/

- Voltage: 380-400V

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

It's┬Ācompact cooking equipment for catering and gastronomic sphere:┬Ācafes, bars, canteens. The cooking equipment is designed for boiling, stewing, frying and mixing products of different viscosity.

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Automatic tilting cooking pots, with lateral support upright designed for cooking solid foods that are transferred by tipping of the container. Options: steam boiling, indirect electric, indirect gas, direct gas. Capacity options: 50, 100, 150, 200, 300, 500l.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Volume: 50l/ 100l/ 150l/ 200l/ 300l/ 500l

- Voltage: 380-400V

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

The price is indicated for the basic version of the set of equipment with a homogenizer

The equipment for the production of ice cream mixtures is based on a universal vacuum reactor with a coolant jacket and a multi-stage dispersant/homogenizer in an external circulation loop.

- Special type of a stirring device for easy disassembly and cleaning

- Processing with minimal product loss

- The bottom outlet valve is included in the basic version of the installation

- Multi-stage disperser for intensive wetting and homogenization of the flowing mixture

- External circulation circuit with a three-way valve for operation/washing of the equipment

- Reinforced agitator drive for thick and viscous mixtures

- Built-in vacuum pump

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Total power, kW: 3

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Vacuum evaporator with remote circulation using a heat exchanger is one of the most efficient evaporation methods. This evaporation system is suitable for boiling and concentrating heat-sensitive products such as milk, cream, etc.

- No mixing device required, the product has forced circulation!

- Modular system: possibility to choose the vacuum generator, power and heat exchanger type

- Inclined design and bottom valve for 100% product discharge without losses and blind spots

- Insulated upper hatch of the unit for heat retention and safety

- Tangential product inlet into the vacuum vessel for guaranteed evaporation in a thin layer

- Material: Stainless steel

- Volume: 50l/ 100l/ 300l

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l