Electric cream cooker with a radiator MKH

This kettle with a radiator cooling system ranging from 30 to 500 liters is ready to cook according to the principle of a water bath.

MKH Series Electric Creamer with a Radiator.

This is a machine that heats and stirs at the same time, and has the additional option of cooling the finished product. The machine can heat and cool the product. The coolant is glycol. The maximum heating temperature is limited to 150C. Glycol cooling temperature down to 1┬░C. Control panel with heating/cooling switch. Glycol circulation pump, connecting pipes and glycol cooler are supplied with the machine.

It is the most popular and suitable installation for large bakeries, confectionery and other food industries businesses.

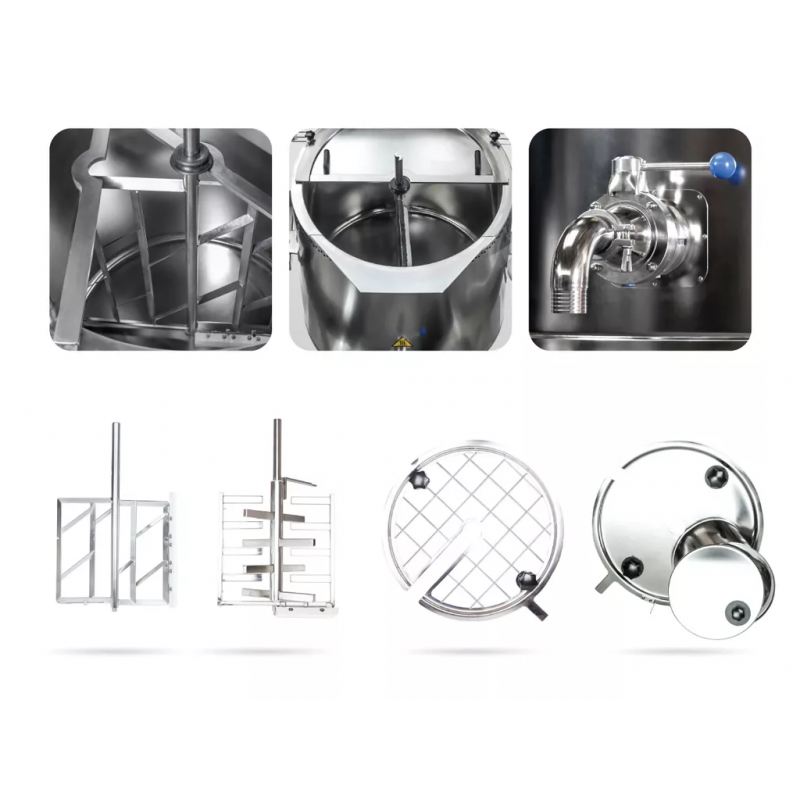

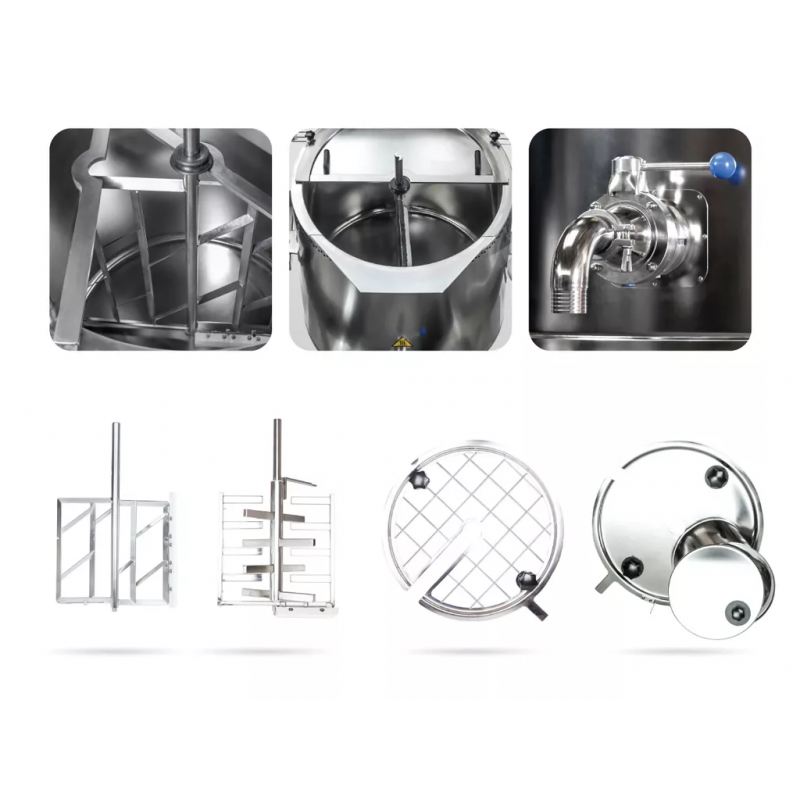

The bain-marie concept always delivers excellent and expected results. This model has a wide range of standard equipment such as a working timer, temperature controller, adjustable stirrer speed (inverter), motorized and easy-to-use bowl tipping system, and a DN-80 hygienic detachable bowl tap. Depending on actual needs, 33%/66% or 100% heating power can be used. This is a very useful feature that has a great impact on cost reduction. The maximum standard temperature is 150┬░C but can be increased upon request. The boiler is entirely made of high quality stainless steel, very durable and designed for heavy duty industrial applications.

The lid of the bowl has a small hopper for adding ingredients or checking the product without stopping the machine. The bowl lid, grate lid and right upright bowl position are protected by sensors so it is not possible to start a machine that is not ready for use. You can choose between standard or special double mix tools. Both tools are equipped with side and bottom scrapers to protect the product from sticking. The electrical system has a phase regulator to always control the correct rotation of the mixing tool. The body/stand of the machine is prepared for use with a standard pump rack, making it easy to move.

Universal boiler with a cooling system:

Machines of the MKH series are designed for the production and preparation of choux pastry, creams, chocolate, fondant masses, jams, glazes, fillings and various mixtures according to original recipes, as well as for any product that requires uniform heating and smooth mixing. Often used in confectioneries and bakeries. The mixing process is carried out by mixing the tool with side and bottom scrapers, which prevent sticking and burning of the mixture. Scrapers are designed to collect layers of mixture from the walls and bottom of the bowl.

- Quick scraper removal system with no tools to clean or replace

- Thermal oil, poured between two wall layers, ensures uniform heat distribution, safe for the product during operation.

- The outer third layer of the bowl prevents heat loss from the machine.

- 2 working speeds (variable on request)

- Maximum temperature up to 150┬░C

All parts in contact with food are made of high quality acid-resistant steel or food-grade materials. Tilting bowl with stop in any position for easy emptying and cleaning - rotating wheel for MK-30,60,80,120 and motorized for MK-200/300/500. A bowl lid with a viewing funnel is present to monitor the process and add ingredients without having to stop the machine. All important electrical components are located inside the electrical box on the side of the machine to prevent smoke and high temperatures.

- Timer - manual or automatic operation

- Safety thermal switch protects against overheating,

- Ball valve DN-80 ŌĆō standard for MK-200/300 and 500 series machines.

- Each machine can be equipped with a bowl tap

- Heating and cooling with glycol

- Cooling of the finished mixture in a short time

Additional configuration options for the cooker:

- Variable speed (inverter) - standard on MK-200/300 and 500

- Fan Cooling System - Available on all models.

- Lid/Bowl Grid - Available for all models.

- Special double mixer - available for all models.

- LCD - 7' - fully programmable control panel with recipes

- Laser product temperature sensor.

- Material: Stainless steel

- Volume: 30l/ 60l/ 80l/ 120 l/ 200l/ 300l

- Voltage: 380-400V

You might also like

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

Universal cooking kettle for thick mixtures: it works on the principle of a water bath and can be used in confectionery shops, bakeries and other catering establishments. Offers a wide variety of models.

- Mechanical tilting system for unloading

- Safety grill for the mixer drive

- Built-in electric heating up to 150 degrees

- Mobile support structure on wheels

- Heating: Electricity

- Principle of operation: Batch mode

- Volume: 30l/ 60l/ 80l/ 120l

This premium cooking kettle is gas-fired and has a capacity of 120 liters. Ideal for preparing a wide variety of dishes.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 120l

- Working volume: 100

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The automatic screw cooker is designed for cooking or blanching various food products in continuous mode, saving both time and energy during production.

- Heating: Mixed

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Stainless steel jam cooking pot with agitator 50l and electric stove 5kW, ideal and affordable cooking solution.

- Heating: Electricity

- Material: Stainless steel

- Engine power, kW: 0,18/

- Heating power, kW: 5

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

Designed for cooking or blanching vegetables, fruits, legumes, pasta, seafood and other products in a continuous manner.

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

Cooking tank with a bottom out of stainless steel AISI 316. Capacity of 150 liters.

- Heating: Steam

- Material: Stainless steel

- Volume: 150l

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Electric cooking boilers are cooking devices powered by electricity, designed for heating and cooking products intended for consumption. They are intended for use in catering kitchens, school kitchens, professional kitchens and other food processing plants.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l/ 150l/ 250l/ 300l/ 350l/

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

Cooking kettle for making syrups, caramel, sugaring paste as well as processing and producing various thick and viscous products. Often used for dissolving sugar and producing various saturated and supersaturated solutions.

- Built-in heating with thermal oil up to 150 degrees Celsius

- Anchor frame stirrer for rapid dissolution

- Conical bottom design of the working container without dead zones

- Heating: Electricity

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 200l/ 300l

- Total power, kW: 19