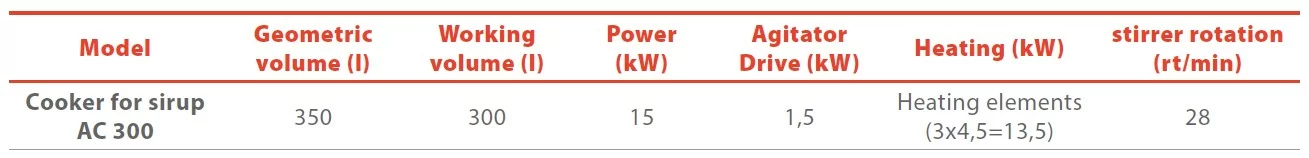

Atmospheric cooking kettle AC 300

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries. Working volume up to, l: 300 l.

Atmospheric cookers AC are designed for efficient mixing, heating and cooking products for the food, pharmaceutical and cosmetic industries such as food preparation, jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and the like.

Cooker / Boiling pan is a device used for heating, cooking and mixing of the product. It is designed to boil different kind of syrup.

The boiler is equipped with two temperature sensors PT 100 (which are used for sensing product temperature and heating fluid). Stirring of the product provides an anchor full-volume mixer, an agitator speed of 28 rpm. The engine is powered by a 1.5 kW motor. The boiler has adjustable legs. It contains the upper door (1/3 of the top cover surface).

The cooker / boiling pan is made of high quality stainless steel AISI 304 and has a double or three-layer construction with insulation. Part can be a stirrer, its type depends on the product. The most versatile is a frame full-volume mixer that perfectly mixes the entire contents of the boiler. A temperature sensor is placed in the boiler that gives the signal to a digital microcontroller that regulates heating. For steam heating, the solenoid valve opens and closes the supply of saturated steam after reaching the selected temperatures.

We offer the following versions of cookers / boiling pans depending on the purpose and requirements of the customer:

- Vacuum boilers

- Atmospheric boilers

- PLC for automatic process control

- Heating gas or el. spirals

- Mixer of choice

- Teflon scraper for stirrer

- Tilted cooker

- Domestic, submerged, inline homogenizer

- To measure the components, it is possible to install a flowmeter,

- Leveling device, strain gauge weighing system

- Sample collection device without process interruption

- Electric drive for product discharge

- Static or rotary CIP head for quick and easy sanitation

- Latch with valve

- Tilt positioning system

- Display window

- Rotating wheels

- Cooling system

- Data recorder, printer for recorder

- Light or acoustic signaling

- Preparation of GMP for Pharmacy

- Material: Stainless steel

- Engine power, kW: 1,5 KW

- Heating power, kW: 13,5

- Principle of operation: Batch mode

- Working volume: 300 l

- Geometric volume: 350 l

You might also like

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Price depends on the chosen option. Please send us a request.┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

This 550 l professional tilting kettle is gas-fired and is indispensable in the professional kitchen. It allows you to easily prepare the most delicious soups, broths, sauces and creams. With this tilting version, you can make your life even easier.

- Heating: Gas

- Productivity: 500 l

- Material: Stainless steel

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

This premium cooking kettle is gas-fired and has a volume of 160 liters. Ideal for preparing a wide variety of dishes in professional kitchens.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

Industrial kettle for cooking and stewing meat, vegetables, seafood, legumes, cereals under pressure up to 0.5 and temperatures up to 110 ┬░C bar.┬Ā

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 600 l

This electric cooking pot has a volume of 60 liters and is used to prepare a large number of dishes. It is comfortable to use and easy to clean.

- Material: Stainless steel

- Volume: 60l/

- Voltage: 380-400V

The universal cooking boiler with an integrated homogenizer and a capacity of 1200 liters is designed for efficient mixing, heating, cooking and homogenizing of products for food, pharmaceutical and cosmetic industries such as jams, marmalades, syrups, fruit juices, nectars, beers, creams, ointments, soaps and many others.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

This kettle is designed to be used by catering companies, canteens, restaurants, small productions and food manufactures.┬Ā

- Heating: Steam

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l/ 500l

The price is set for the basic fryer version without additional modules. If purchasing the fryer together with both of the additional conveyor modules ŌĆō the double conveyor fryer and the paddle conveyor fryer ŌĆō we offer a discount of 300 EUR.

The versatile modular conveyor fryer with a single conveyor belt is used for the continuous frying of a variety of products with a low moisture content, that do not require forced immersion beneath the surface of the oil for even frying.

- Adjustable frying time from a few seconds up to an hour!

- Ability to use the unit as a continuous blancher or boiler for cooking products with a delicate structure

- Modular system, expanding functions with each new module

- Compact, desktop version

- Possibility of periodic frying of products with automatic unloading

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Working Area Length: 1100 mm

- Working Area Width: 400 mm

- Oil volume: 60l

- Voltage: 380-400V

The Atmospheric Evaporating Pan efficiently concentrates liquids by evaporating them on a large surface area, while also being suitable for various cooking methods including braising, cooking, and roasting.

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The tilting cooker is produced in 2 versions: with gas or electric heating. The pan is designed for use in the food, hospital, catering industry and in large kitchens for making pasta, stewing and frying meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, etc.

- Principle of operation: Batch mode

- Volume: 50l/ 80l/ 120l

- Voltage: 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

A modern cooking and mixing device with a wide range of applications in confectionery, bakeries, catering establishments.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

Universal cooking kettle with a built-in steam generator up to 0.5 bar, frame stirring device and an automatic tilt and unloading system is a convenient and safe solution for processing various liquid products in large volumes.

- Safe design with a jacket (duplicator) and outer casing with insulation

- Intensive steam heating through the jacket using the built-in electric steam generator

- Automatic multi-stage tilt and unloading system

- Frame stirring device for dissolving, mixing, kneading ingredients

- Unloading of the product into rolling carts is possible due to the offset tilted axis

- Heating: Mixed

- Material: Stainless steel

- Country of origin: Slovakia

- Total power, kW: 13,5

Price depends on the chosen option. Please send us a request.┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The universal bath pasteurizer is used for processing a wide range of different food products, such as ready meals, sausages, hams or liquid products. Effective temperature regulation and a hygienic stainless steel design.