The mixing tank facilitates efficient heating and cooling through two interconnected pressure duplicators, ensuring the optimal temperature control of the product.

For heating, a heat exchanger, assisted by a pump, is employed. Constructed from high-quality stainless steel AISI 304, the tank features a three-layer design with an insulating double conical bottom and two interconnected pressure duplicators.

To prevent product adhesion and enhance cleaning efficiency, Teflon wipes sweep the container walls. A bottom ball valve is provided for drainage.

The interconnected duplicators also play a crucial role in effective cooling using cold water. A temperature sensor inside the container signals a digital microcontroller, precisely regulating the heating and cooling processes. The solenoid valve manages the cold water supply based on the set temperatures.

As the microcontroller initiates the heating process, the pump circulates hot water into the duplicator at the bottom of the vessel. Temperatures are meticulously recorded on the digital temperature recorder, all managed through the equipment's electric control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

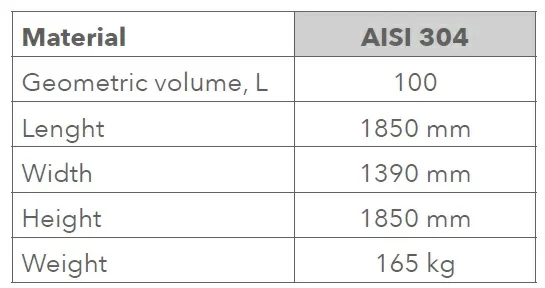

- Geometric volume: 100 l

You might also like

Heating boilers are designed to cook sausages, hams and o’¼Ćal. Technology for superior performance and hygiene.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l/ 400l/ 500l/ 600l/ 800 l / 1000l/ 1200l/

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

Price depends on the chosen option. Please send us a request.┬Ā

- Heating: Electricity Steam

- Material: Stainless steel

- Engine power, kW: 2,2

- Volume: 300l

- Dimensions, mm: 1070x1120x1040

If you need to cook the product at low temperatures, to better preserve the appearance and nutritional properties of the product, or to add components that are sensitive to heat, we recommend using the universal TiltCook boiler.

- Heating: Electricity Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 250l/ 300l

Double-jacket stainless steel cooker for marmalade and jam production.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 100l/ 200l/ 300l

- Voltage: 380-400V

The price is set for the basic version of the reactor without additional options and the control panel

The vacuum vessel with a coolant duplicator and a mixing device is a universal solution for processing various products at sub-atmospheric pressure. Based on this simple device, you can select and modulate it into complex installations such as a┬Āvacuum evaporator, a┬Āvacuum cooking kettle, and a┬Āunit for the production of cream honey.

- Sloped Design - Gravity Mixing

- Bottom valve DN40 included in the basic version

- Small-volume duplicator - low costs for coolant heating/cooling

- Modular system: customization of the equipment and its functionalities by ordering additional options

- An easy to disassemble mixing device

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The 1000 L vacuum cooker is used for cooking, concentrating, and evaporating food products under reduced pressure, allowing gentle heat treatment, improved flavor retention, and precise control of moisture content.

For a price quote, send us a request.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 1000l

- Dimensions, mm: 1385x1283x1892

The vacuum cutter is intended for large processing enterprises dealing in the confectionery, fruit and vegetable processing industries. They are intended for processing food down to a homogenous mixture with minimal air content.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

A vacuum cooker is used in the food processing industry to cook ingredients under reduced pressure, typically in a vacuum environment. This method allows for precise temperature control and faster cooking times while preserving the quality and flavor of the ingredients.

We offer different vacuum cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2500 l

The VMG S 650P vacuum homogenizing unit can be used for making toothpaste as well as a variety of similar products with complex production requirements.

- The vacuum ensures effective air removal, eliminating the conditions for the development of bacteria and other pathogenic organisms.

- The special shape of the mixing device is tailored for the thickest and most viscous products.┬Ā

- The Ultra Shear submersible homogenizer creates a stable emulsion.

- The cavitation processes aid in activating hydrodynamic mixing.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 29

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 52

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

This 800-liter capacity dissolver with a circulation pump is designed for preparing liquid solutions by dissolving substances directly in water or other working fluids. It is used in the food and beverage industries for ensuring uniform dissolution through hydrodynamic mixing in a forced recirculation loop.

Recirculation with a food-grade pump ensures rapid and uniform dissolution without sedimentation or the formation of stagnant zones. The working tank is mounted on a mobile platform with wheels, allowing for easy and quick movement between production areas.

- Fast and uniform dissolution without sediment thanks to hydrodynamic mixing

- Forced recirculation loop with product pump/inline homogenizer (optional)

- Mobile stainless steel platform on wheels

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Geometric volume: 800 l

The price is set for the basic version of the installation without additional equipment.

The vacuum homogenizer is designed for a wide range of processes such as for the production of mayonnaise, ketchup, various sauces, confectionery pastes and fillings, liquid or paste like products with a homogeneous structure. It is also suitable for the production of various creams, gels, shampoos and other products in the cosmetic industry.

- Built-in Ultra Shear bottom homogenizer

- Mixing device with movable scrapers

- Tilting version for easy unloading

- Wide range of applications

- Entirely made of food grade stainless steel AISI304/ AISI316 - option

- Compact design

- Lots of additional options to choose from

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 20l/ 50l

- Total power, kW: 2,3/ 2,4

- Voltage: 220-230V

- Max vacuum: -0,8 Bar

Multifunctional vacuum unit MINI5 - is ideal for cooking, drying, concentrating, mixing and much more. Suitable for laboratories and small-scale production.

- Processing heat-sensitive products at lower temperatures

- Ideal for making creamed honey

- Possibility of vacuum drying honey

- Material: Stainless steel

- Engine power, kW: 0,12

- Country of origin: Slovakia

- Volume: 5l

A vacuum deaerator is extensively used in the food industry to remove gases from products that may retain some bubbles post-processing. Additionally, a flow deaerator is utilized to minimize foaming in products, ensuring a denser structure, especially prior to packaging. Vacuum deaerators play a crucial role in eliminating specific odors from the products, such as in the production of juices, purees, and herbal drinks. This process significantly contributes to enhancing the overall quality and taste of the final product.

- Enhances product quality, structure, and shape

- Prevents oxidation by removing gases

- Preserves organoleptic properties and extends the shelf life

- Suitable for thick and viscous products

- The flow principle allows for the installation of this equipment in existing production lines

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

It is ideal for cooking jams, marmalades, syrups, sauces, creams and other products.

Price depends on the chosen option.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

- Geometric volume: 350 l

Universal cooking kettle with a built-in mixer, used for cooking and stirring a variety of food products, cosmetic emulsions, creams and much more.

- Easily removable self-adjusting scrapers

- Lid opening sensor for safe stirrer maintenance

- Hygienic temperature sensor for the product

- Large diameter outlet valve

- Safe steam outlet on top of the boiler lid

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

The vacuum evaporation unit is specially designed for thickening dense food products in industrial quantities. The evaporator can be used for the production of thick syrups, caramel masses, dense fruit masses, as well as for the production of pectin, or heat-stable fillings with a high productivity.

- High performance

- Rotary spraying system with a powerful electric drive

- Evaporation in a thin layer with a large heat transfer area

- Low investment installation costs

- Tangential entry for product swirling

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Voltage: 380-400V

Professional cooking boiler with a stirrer for particularly thick and viscous products. An excellent technical solution for the production of caramel, syrups and sugar paste for sugaring. The heating source is selected separately.

- The kettle can be used on all types of cooking surfaces, including induction

- The basic version has easily removable, self-aligning stainless steel scrapers

- High torque of the stirrer with 14-18 revolutions per minute

- Professional 3-phase industrial motor

- The stirrer is turned on independently using a remote control with IP66 protection, connected to the boiler using quick-release connectors

- The unit can be connected to a 220-230 volt network even with a 3-phase motor!

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Volume: 20l/ 50l/ 100l/ 150l

- Voltage: 220-230V

- Diameter, mm: 400/ 500/ 600

This equipment is often used for temporary storage and transportation of liquid products, equipped with a specially shaped stirrer and heating / cooling "jacket".

- Material: Stainless steel

- Engine power, kW: 0,25

- Principle of operation: Batch mode

- Voltage: 380-400V