Industrial pressure cooker VKPI

Industrial kettle for cooking and stewing meat, vegetables, seafood, legumes, cereals under pressure up to 0.5 and temperatures up to 110 ┬░C bar.┬Ā

Pressure kettle VKPI┬Ā is designed for highly efficient heat treatment under pressure. You can use it for cooking and stewing┬Āa wide range of food products at temperatures up to 110 ┬░C and pressure up to 0.5 bar.

Thanks to a considerably short cooking time, the finished product retains maximum amount of vitamins, minerals and nutrients, also its attractive appearance, perfect taste, and smell.

Suitable products:

- Meat

- Vegetables

- Seafood

- Legumes

- Cereals

- etc.┬Ā

The cooking process may controlled by a PLC display with the possibility of storing data with transmission┬Āon USB key.

The cooking kettle is made out of high-quality stainless steel AISI304 suitable for use in the food industry.┬Ā

Electric actuator for lid opening

The mechanism allows lids to he automatically opened from the ground using a controller that opens and closes the lid as desired.

Rapid heating allows optimum estimation of the heat treatment time of the product in the boiler and prevents its booming. Thanks to the intense circulation of water through the pump, the tank walls do not burn. The other option is direct steam.

Direct steam option benefits

- Instantaneous Heating

- Process Flexibility

- Reduced Energy Consumption

- Lower Maintenance Cost

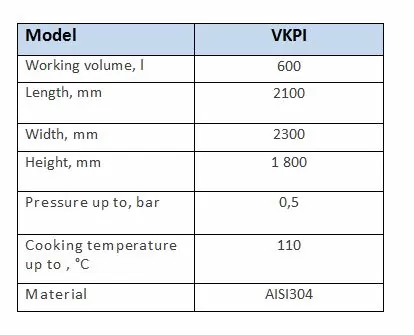

Technical data:

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 600 l

You might also like

Cooking kettles for cooking under pressure are designed for highly efficient heat treatment of a wide range of food products at temperatures up to 110 ┬░C and pressure up to 0.5 bar.

- Heating: Electricity Steam

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 220 l/ 500l/ 600l/

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: 220l/ 500 l

Heating: integrated electric. Price depends on the production capacity and product.┬Ā

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. This is 150l capacity.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l

The cooking boiler is equipped with a jacket for heating as well as a heating system, an electrically driven stirrer (with a geared motor) and Teflon scrapers, which allow for the processing of products with low to medium viscosity. The cooking device is also equipped with a vacuum system.

- Productivity: 100l

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

The compact line of double-type vacuum cooking kettles comprises a complex of batch food cooking units designed for periodic thermal processing, vacuum mixing, and deaeration of various products under sub-atmospheric pressure.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 2x300l/ 2x600l

A cooking kettle and a vacuum mixer for periodic deaeration of products such as mayonnaise, ketchup, various sauces, creams, gels and pastes. It is one of the modifications of a vacuum reactor and a vacuum evaporator. The presence of a vacuum system allows you to create a vacuum after the cooking process and perform vacuuming (deaeration) to remove air bubbles with potential contaminants and obtain a product with a denser structure. Thanks to vacuuming, the product has an extended shelf life, since pathogens and microbes contained within are removed together with the air.

- Inclined design with gravity mixing, which is 30% more efficient than usual

- 100% emptying of the product after processing due to the bottom valve

- Easy to disassemble removable mixing device

- Possibility of connecting it to a CIP station for cleaning and washing

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 100l

- Total power, kW: 0,12

- Max vacuum: -0,8 Bar

Modern equipment with a wide range of applications in pastries, bakeries, catering facilities.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 500l

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. We offer 100l, 150l, 250l and 300l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l

The price is stated including the unheated conical side panels

The frying pan of the WOK type with direct electric heating is designed for fast and intensive heat treatment of products with a maximum heating temperature of up to 220 degrees. This equipment allows you to saut├®, fry, stew, boil, cook and concentrate various products, including thick and viscous ones thanks to the frame mixing device and an automatic tilting system for unloading the final product.

- Fast and efficient heating of up to 220 degrees

- Automatic tilting and unloading system

- Lid opening sensors for safe operation

- Safe steam exhaust system on the top lid

- Lid latches in the open position

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 45

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Total power, kW: 46

- Voltage: 380-400V

Unbeatable price, excellent cooking results, designed to be placed in tight spaces where sharp edges or corners may create problems. We have different capacities boiling cookers.

- Material: Stainless steel

- Heating power, kW: 18

- Volume: 150l

- Voltage: 380-400V

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Heating: Gas

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 60l/ 80l/ 100l/ 150l/ 200l/ 250l/ 300l

A universal cooking & cooling system for preparing large batches of food and subsequently cooling them down to preserve their structure.

Price depends on the selected options. For more information, please send us a request.┬Ā

- Heating: Steam

- Material: Stainless steel

- Working volume: 700l

- Geometric volume: 1000 l

- Dimensions, mm: 3180x1860x1080

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

The innovative cooking device combines the advantages of cooking with automatic mixing and compact dimensions.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 50l/ 150l/ 200l/ 300l/ 500l

The electric cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, broths, pasta, milk dishes, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared meals, heating or steaming. The equipment is not suitable for roasting or baking.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 18/ 24/ 30/ 36

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Volume: 100l/ 150l/ 200l/ 300l

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.┬Ā

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90