Beer brewing kettle

You don't need professional equipment or special skills to brew beer at home; all you need is to buy a spacious kettle with an automatic stirring device!

- Special mixing device prevents malt from sticking to the bottom.

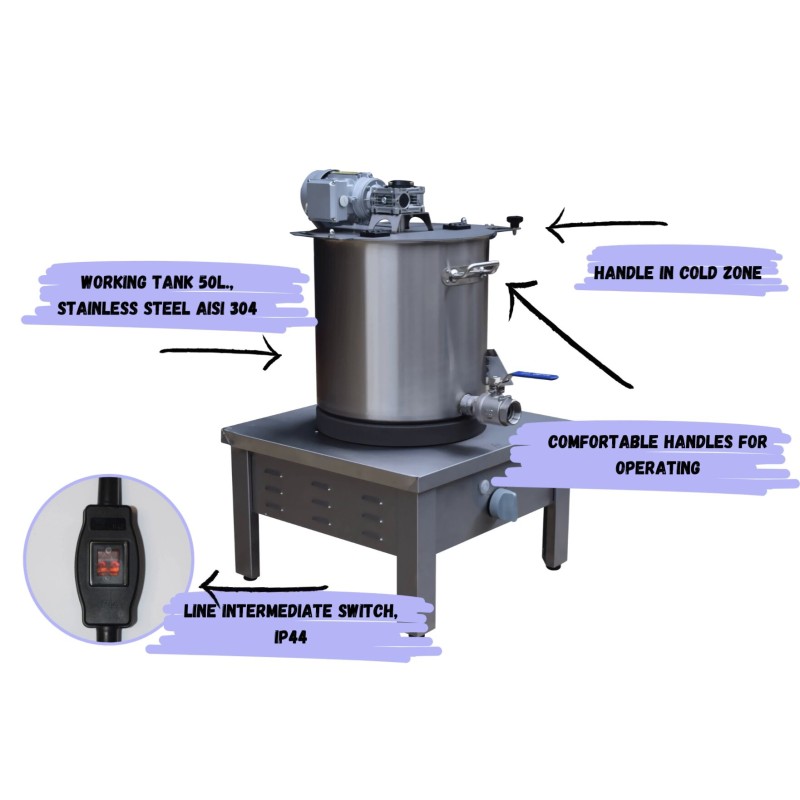

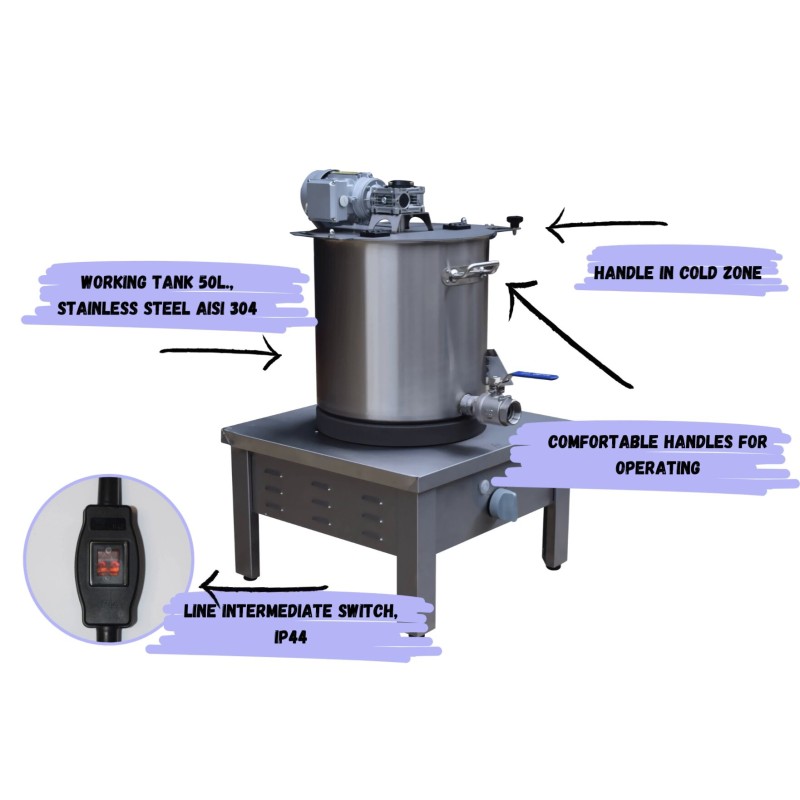

- The cooking kettle has two side handles for easy manipulation.

- The kettle, lid, and outlet valve are made entirely of stainless steel.

- The beer kettle can be used on any stove or you can purchase an electric base along with the kettle (optional).

A home brewing kettle allows you to make both light and dark beers. Depending on the recipe, you can brew either top-fermented or bottom-fermented beer if you prefer a hoppy taste.

For a classic recipe, it is enough to buy ready-made ingredients such as malt or malt extract, hops, and yeast. It's crucial to use high-quality water - it should not only be clean but also soft, meaning it is best to use filtered, boiled water or water from artesian springs. Depending on the recipe, you can add honey, bread, jam, or molasses to the beer.

Advantages:

- You can accurately control the beer brewing process thanks to a thermometer installed directly on the body of the kettle.

- The presence of a mixing device and intensive mixing is necessary to saturate the beer with oxygen during the brewing process.

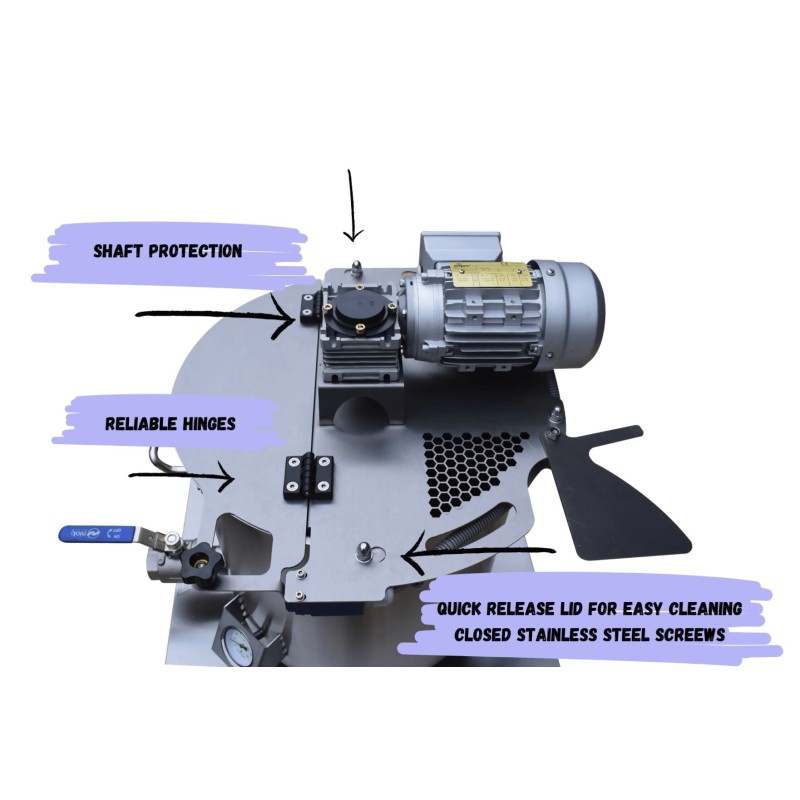

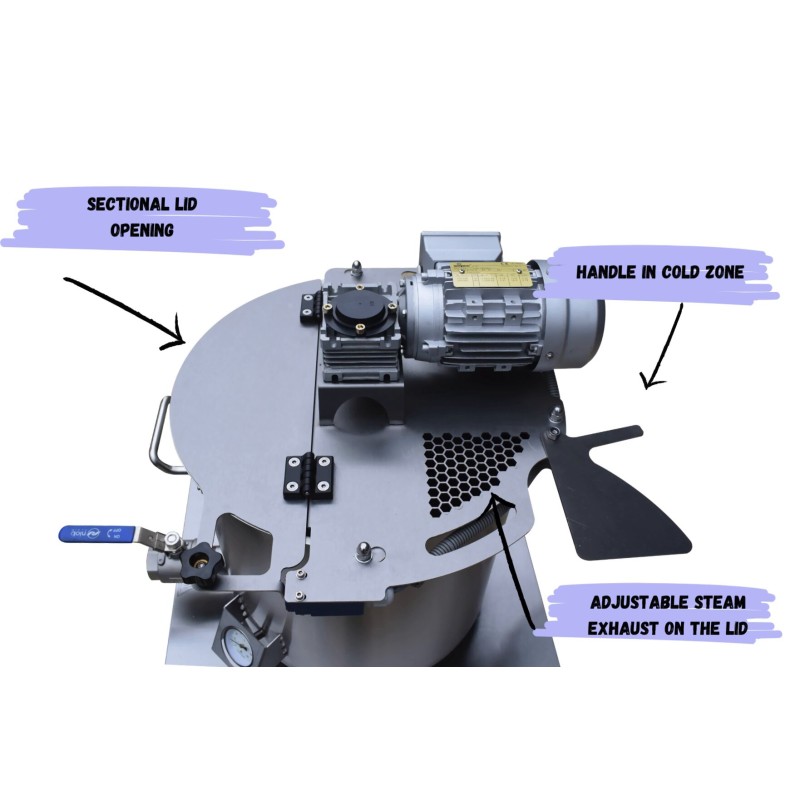

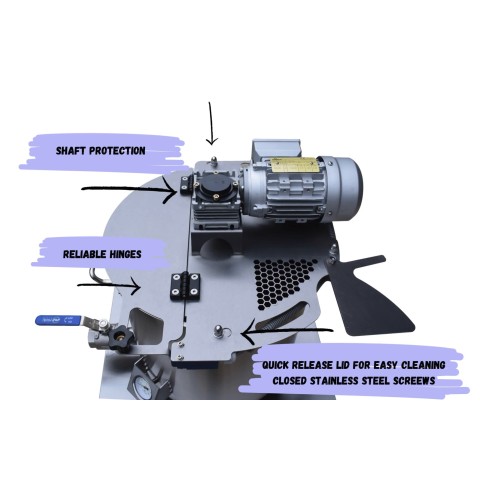

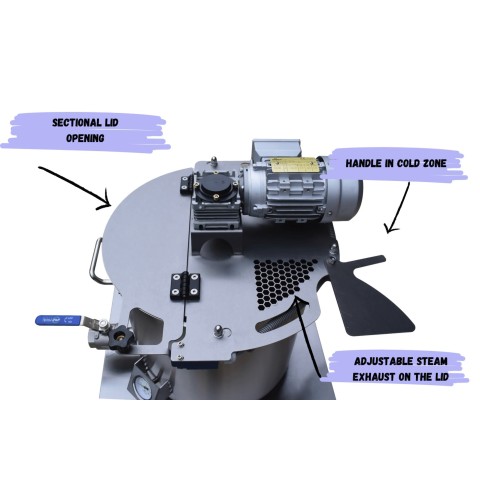

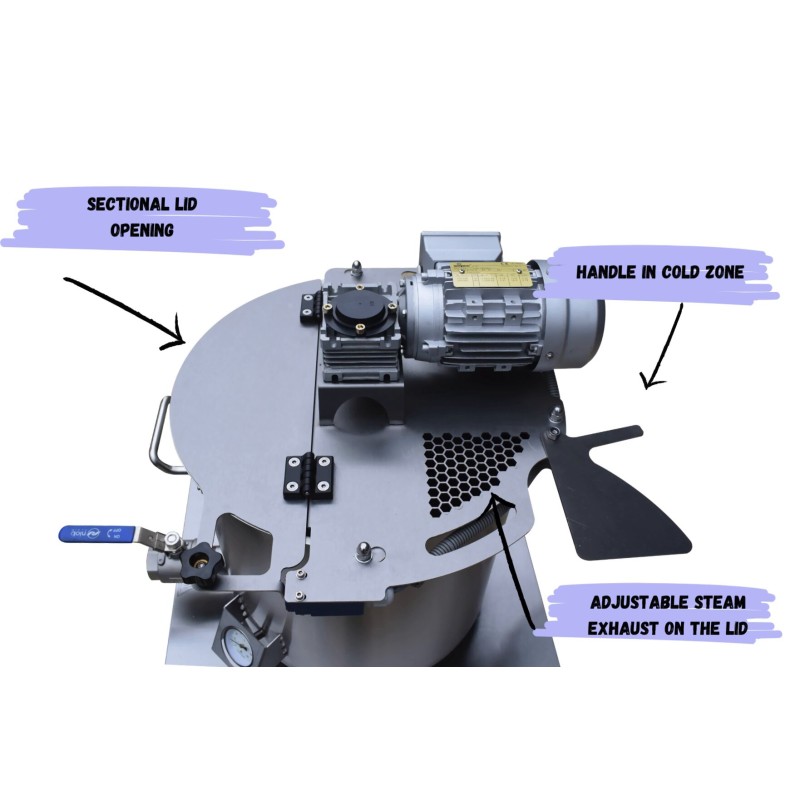

- The top hatch features a sectional opening and a special damper for removing secondary steam, which can be closed to completely isolate the product from aeration, which is particularly important during the beer fermentation process.

- The large outlet valve allows you to quickly and completely empty the kettle, which is important for high-quality filtration of malt porridge.

Basic Version:

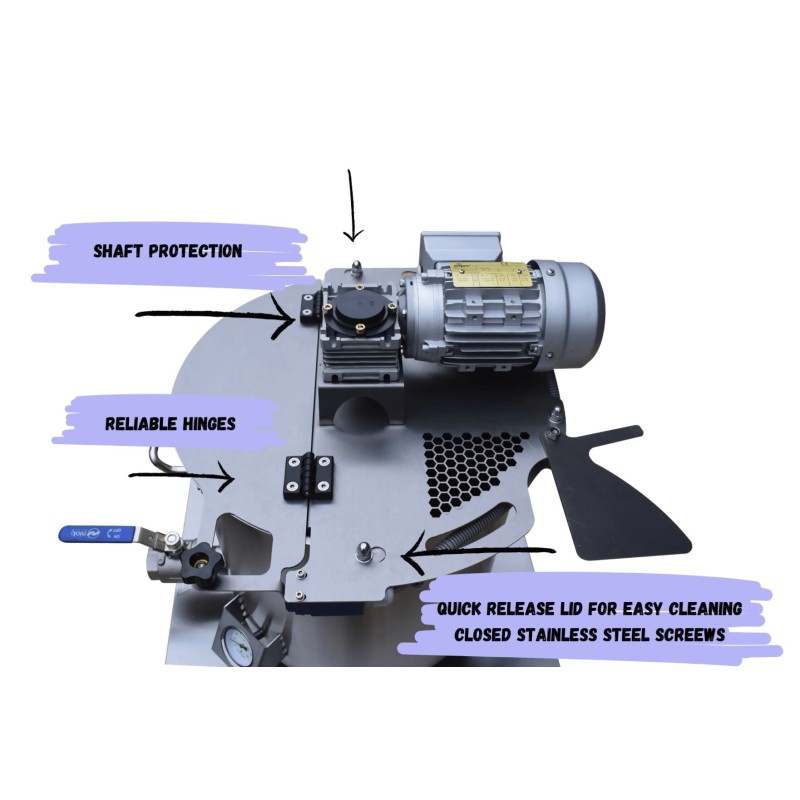

The beer brewing kettle consists of a thick-walled stainless container with a multi-layer bottom which allows for the possibility of using any heating source (electric, gas and induction), an automatic mixing device for constant mixing with fluoroplastic scrapers, a safe switch for turning the mixing device on and off, a quick-release hatch with a lid opening sensor, lid holders located in the cold zone, steam exhaust section with a damper, professional industrial single-phase motor connected to a regular 220-230 Volt outlet. The basic version also includes a thermometer for monitoring the processing temperature and a release valve at the lowest point of the kettle.

Examples of beer recipes:

Homemade Beer Without Malt

Ingredients:

- 10 liters of water

- 1/3 cup hops

- 1 cup liquid brewer's yeast

- 0.5 liters of molasses

Process:

Pour water into the kettle, add molasses, stir well, bring to a boil and cook until the smell of molasses disappears. Place hops wrapped in cheesecloth into the liquid and boil for 10 minutes. When the mixture has cooled, add liquid yeast and mix thoroughly. Pour the beer into bottles and leave them open until foam forms on the surface. Skim off the foam, seal the vials and store in a cool place for 4 days.

Hoppy Beer

Ingredients:

- 900 grams of sugar

- 90 grams of hops

- 1 kilogram of malt extract (or 8 kilograms of malt)

- 9 liters of boiling water

- 50 grams of brewer's yeast

Process:

Mix sugar, hops and malt with boiling water and cook for one hour. Add water to restore the original volume (9 liters) and add yeast. Leave the mixture in a closed container at 18â20°C (64â68°F) for 3 days. Strain, bottle, cork, secure the lids with wire and store in a cool place for a week.

Options

- Material: Stainless steel

- Engine power, kW: 0,18/ 0,25

- Principle of operation: Batch mode

- Volume: 50l/ 100l/ 150l

- Voltage: 220-230V

- Outlet valve, inches: 6/4

- Diameter, mm: 400/ 500/ 600

You might also like

The brewery boiler comprises a two-pot-shaped assembly, in which the integrated frame is a built-in lauter tun, a mash tank, a whirlpool, a laboratory sink and a control panel.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 1800l

The 5 kw stool-type electric heating stove with a diameter of 40 cm is designed to heat large pots and pans with a volume of up to 100 liters.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 5

- Type of the equipment: Optional equipment

A hydraulic crane hoist with a hook is a mechanical device designed to lift and move heavy machinery or engines, commonly used in industrial settings as well as automotive repair for safe and efficient handling of heavy loads.

- Type of the equipment: Optional equipment

The kettle is designed for cooking qualitative jam, marmalade, confiture from different fruits, vegetables and berries. It's an ideal and affordable solution for cooking various products.

- Material: Stainless steel

- Heating power, kW: 9/ 12/ 18/ 24

- Principle of operation: Batch mode

- Volume: 80l/ 120 l/ 200l/ 300l

The vacuum homogenizer is designed for whipping mayonnaise, ketchup, various sauces, confectionery pastes and fillings, condensed milk, jams and marmalades, canned goods, as well as similar liquid or pasty products with a homogeneous structure.

- Homogenizer in an external circulation loop

- Built-in vacuum generation and retention system

- Modular design with numerous options

- Possibility of automatic dosing of ingredients (optional)

- No additional pump required for loading/unloading

- Automatic top cover lifting system

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 650l

- Total power, kW: 13,5

- Voltage: 380-400V

- Max vacuum: -0,8 Bar

Wide range of catering equipment for restaurants, canteens and all kinds of food serving establishments.

- Material: Stainless steel

- Heating power, kW: 12/ 18/ 24

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: EU

- Voltage: 380-400V

The Steam Cooking Pot allows you to cook large batches of your signature soups, stews and pasta as well as steaming and boiling of semi-finished products.

- Heating: Steam

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 200l/ 300l/ 400l

The cost is indicated without the control panel, which can be selected and offered separately

A versatile cooking system, featuring an inclined reactor, a duplicator for heating and a frame mixing device, it is designed for processing a diverse range of products through methods such as cooking, boiling, and concentrating at atmospheric pressure. This system is commonly used for the production of syrups, jams, confiture, and honey processing.

- Slanted design with gravity mixing - 25% more efficient!

- External decorative casing made out of polished stainless steel with insulation

- Jacket for the bottom and the walls of the working container along the entire height

- Lid opening sensor for safe operation

- Scrapers are already included in the basic version of the installation

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l/ 300l/ 430l/ 600l/ 1000l

- Voltage: 220-230V 380-400V

Heating: integrated electric. Price depends on the production capacity and product.Â

- Heating: Electricity

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 300l

A Vacuum cooker is a versatile device used in culinary settings to cook food under vacuum conditions, enhancing flavors and textures while also reducing cooking times.

We offer various different cookers.

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 100l

- Voltage: 380-400V

These gas boiling cookers are manufactured for professional kitchens and also for other food processing factories. We offer 100l, 150l, 250l and 300l.

- Material: Stainless steel

- Principle of operation: Batch mode

- Volume: 150l/ 200l/ 300l

The vacuum cooking and mixing tank is used to boil products at low temperatures, which helps preserve the natural color, taste and nutrients in the product.

Vacuum equipment is used for cooking premium-quality jams, sauces, fruit and vegetable concentrates.

- Inclined design

- Efficient emptying

- High hygiene standards

- Material: Stainless steel

- Principle of operation: Batch mode

- Type of the equipment: Individual machine

- Country of origin: Slovakia

The electric kettle with a stirring device and manual tilting is suitable for a wide range of applications in food production or professional kitchens. It has an independent frame and built-in intensive electric heating with a wok-shaped, multi-layer âsandwichâ base, allowing the heating temperature to reach up to 200 °C.

- High processing temperatures of up to 200 °C

- Built-in, powerful 2,6 kW / 6,5 kW electric heating

- Manual tilting and unloading system with three working positions, allowing a maximum tilt angle of 110°

- Professional high-temperature thermometer with a probe in the product

- Air insulation of the outer casing

- Stirring device with stainless steel scrapers for high-temperatures

- Material: Stainless steel

- Engine power, kW: 0,25/ 0,37

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

- Stirrer speed, rpm: 18

A versatile atmospheric kettle suitable for cooking various products, including jams, syrups, sauces, fruit and vegetable juices, and many others.

- Material: Stainless steel

- Country of origin: Slovakia

- Volume: 250l/ 300l

Tilting pans with mixers cook the product with continuous stirring and subsequently discharge the food into receiving trolleys, ensuring the discharge spout remains at a constant height from the ground. Designed for the catering industry, large kitchens, school cafeterias, restaurants, and other food production businesses.

- Heating: Electricity Gas Steam

- Material: Stainless steel

- Engine power, kW: 0,75

- Heating power, kW: 24/ 36/ 48

- Volume: 200l/ 300l/ 500l

- Steam consumption, kg/h: 85/ 100/ 115

A vacuum evaporator is a device used to evaporate liquids at lower temperatures by creating a vacuum environment, which reduces the boiling point of the liquid and enables efficient evaporation without thermal degradation of sensitive materials. Working volume up to, l: 1900 l.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 30

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Working volume: up to 1900 l

The multifunctional cooking and pasteurization kettle with manual tilting is a simple device designed for the entire jam production process: from cooking the fruit mixture to the subsequent pasteurization of finished products directly in jars. It allows you to prepare the product in a container and then, using an additional basket, pasteurize the filled jars without the need for any additional equipment.

- 6-stage regulation of the built-in heating allows you to set the optimal conditions for cooking the fruits and subsequent pasteurization without the risk of burning or loss of quality.

- The manual tilting mechanism with a three-stage adjustment and a maximum tilt angle of 110° ensures convenient emptying of the container and dosing of the finished product with virtually no losses.

- Heating: Electricity

- Material: Stainless steel

- Heating power, kW: 2,6 / 6,5

- Volume: 50l/ 100l

SnackPro blancher will prepare different types of products making it a great solution for blanching large volumes of fruits and vegetables in a short time.Â

- Heating: Electricity

- Heating power, kW: 40/ 90

- Principle of operation: Continuous mode

- Country of origin: Slovakia

The steam cooker is intended for use in the food, hospital, catering industry, in large kitchens for making soups, pots, pasta, milk dishes, teaspoon cooking, stewing meat, fish, vegetables, mushrooms, frozen or semi-prepared, ready-to-cook meals, heating or steaming.

The cooking equipment is not suitable for roasting or baking.Â

- Material: Stainless steel

- Volume: 100l/ 150l/ 200l/ 300l

- Steam consumption, kg/h: 50/ 60/ 70/ 90