Chocolate ball mill refiner AKBR

We offer different capacity ball mills, from laboratory mills to industrial mills at great price and highest quality which produce exceptional chocolate.

For more information, send us an email at sales@foodtechprocess.com

Chocolate ball mill grinds the chocolate cream homogeneously

Chocolate ball mill machines are batch type refiners which are used to mill the chocolate cream (natural or palm based chocolate, cream or similar products), by using some steel balls which will grind the chocolate cream homogeneously up to 22-26 micron in the double jacketed stainless steel tank with the temperature controller.

Different capacity ball mills┬Ā

We offer small capacity 10l/2h ball mill refiner suitable for laboratories or universities. The unit can be used for product development or educational use. We also offer bigger capacity AKBR 30, 50 and 100 for artisans & small work shops are with similar characteristics like the industrial ball mills.

OPTIONAL:

- Top lid with safety sensor

- stainless steel pump┬Ā

Industrial type ball mills AKBR 300, 500:

- Planetary gearbox is more durable against traditional ones

- Torque capacity of planetary gearboxes is very high thanks to shared load between the gearwheels

- Water jacketed and insulated AISI304 grade stainless steel reservoir.

- Self heating.

- Temperature control ensured by ON/OFF thermostat.

- Chocolate transfer pump.

- Water jacketed 3 way valve.

- Heat treated mixing arms and shaft.

- Solenoid valve to open or close gate of cold water.

- Cold water chiller (optional).

AKBR 30, 50, 100

Ball refiners for artisans & small work shops are with similar characteristics like the industrial ball mills.

- Directly coupled worm gearbox for the mixing shaft.

- Water jacketed AISI304 grade stainless steel reservoir.

- Self heating.

- Temperature control ensured by ON/OFF thermostat.

- Chocolate transfer pump.

- Water jacketed 3 way valve.

- Heat treated mixing arms and shaft.

- Solenoid valve to open or close gate of cold water.

- Cold water chiller (optional).

AKBR 10 Laboratory ball refiner

Ball mill refiner with suitable capacity for laboratories or universities. The unit can be used for product development or educational use.

- Directly coupled worm gearbox to the mixing shaft.

- Water jacketed AISI304 grade stainless steel reservoir.

- Self heating.

- Temperature control ensured by ON/OFF thermostat.

- Manually discharging.

- With a screw pump to allow mass circulation from bottom to top.

- Reverse rotation of the screw pump while discharging.

- Bottom discharging tray.

Industrial ball mill with heat treated mixing arm

Mixing arm is made of special material which is subsequently heat-treated. With coupled chocolate pump and three-way valve, there is possibility to circulate the mass or discharge (transfer refined product to the storage tank).

Suitable products for a ball mill

- chocolate cream

- natural based chocolate

- palm based chocolate

- cream

- other similar products

The washer-auger-mill machine is designed for washing, transporting and milling whole fruit or vegetable before further processing.

Price depends on your product and the production capacity. For more information, send us a request.

Grinding mill for continuous grinding of meat and ingredients such as seeds, small bones and cartilages that are unwanted in the final product.

For more information, send us an email at sales@foodtechprocess.com

The knife mill is used for grinding products such as sugar, pepper, dry leaves and other products that are used during the production of spices and sauces.

- Adjustable grinding size

- Easy maintenance

- Support structure

- Large capacity hopper

- Material: Stainless steel

- Engine power, kW: 5,5

- Principle of operation: Continuous mode

- Voltage: 380-400V

- Hopper volume, l: 30

Ball mills are used for the production of a chocolate mass, various types of chocolate glazes, nut and chocolate pastes (such as Nutella) and similar products.┬Ā

Chocolate flaking machine for automatically differentiating two blocks of couverture each time. The flakes are collected in plastic baking for food. The machine comes with two plastic bins.

Stand (support structure) for colloid mill machine - additional option for the colloid mill 132

For more information, contact: sales@foodtechprocess.com

We offer different types of washing equipment for various different fruits and vegetables.

For a price quote or a free consultation, email us at sales@foodtechprocess.com

The new and improved version of the colloid mill is used for continuous grinding, to obtain a finished nut paste product of various viscosities, without requiring additional processing or preparation!

You can send us a request at┬Āsales@foodtechprocess.com

- Simple and easy operation

- Three-point chopping adjustment

- Possibility of producing both creamy and crunch-type nut butters

- Compact design

- High performance

- Productivity: 180-240 kg/h

- Material: Stainless steel

- Principle of operation: Continuous mode

- Country of origin: Slovakia

- Voltage: 380-400V

The crusher is used for crushing fruits such as berries before pressing. The price depends on your production.┬ĀFor more information, send us a request.┬Ā

The industrial meat grinder is made out of food-grade stainless steel. The kit includes various accessories such as a sausage attachment and an attachment with two cross blades. The productivity of the meat grinder is around 120 kg of minced meat per hour.

- Compact

- Professional

- With anti-slip rubber feet

- Stainless steel housing

- Material: Stainless steel

- Operation mode: Automatic

- Principle of operation: Continuous mode

- Total power, kW: 0,75

- Voltage: 220-230V

This authentic grain mill is perfectly suitable to grind excellent quality flour even in big quantities.

For more information, send us an email to sales@foodtechprocess.com

Fruit crushing mill, entirely made of AISI 304 stainless steel is suitable for fruit, vegetables and for many other products such as apples, pears, carrots, lemons and others; easy to use, high productivity. It can be supplied with one or more sieves (screens or riddles).

For a price quote, send us an email to sales@foodtechprocess.com

- Productivity: 800 kg/h/ 1500 kg/h/ 3000 kg/h

- Engine power, kW: 1,35/ 2,1/ 2,6

- Hopper volume, l: 30/ 60/ 100

The nut grinding machine is used for processing sesame seeds to produce a tahini or a sesame paste.

For more information, please contact our sales department at sales@foodtechprocess.com

The mill is designed for milling whole fruit or vegetable before further processing. Price depends on the chosen fruit and production capacity.

For more information, send us a request.┬Ā

The price is stated for the basic version of the installation without balls.

The mill is designed for mechanical grinding of raw materials for the production of chocolate, nut butters and obtaining a creamy, homogeneous product structure with a fraction size of up to 20 microns.

- Compact installation on a self-supporting structure

- Simple and convenient maintenance

- Plexiglas cover for visual inspection

- Removable stirring device

- Jacket for the heat transfer medium

- Material: Stainless steel

- Principle of operation: Batch mode

- Country of origin: Slovakia

- Volume: 5l

- Total power, kW: 1,5

- Voltage: 380-400V

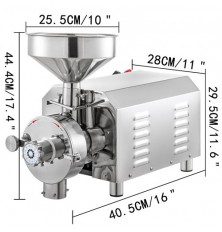

This powder making machine is made out of stainless steel. All parts that are in contact with food are made out of food grade 304 stainless steel for health and safety reasons.

For additional information, contact us at sales@foodtechprocess.com